Control switch for increased operational safety

A technology to increase operation and control switches, which is applied in the direction of electric switches, electrical components, emergency actuators, etc., can solve the problems of switch jamming, leakage, and unguaranteed service life of switches, and achieve rapid return and guaranteed service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

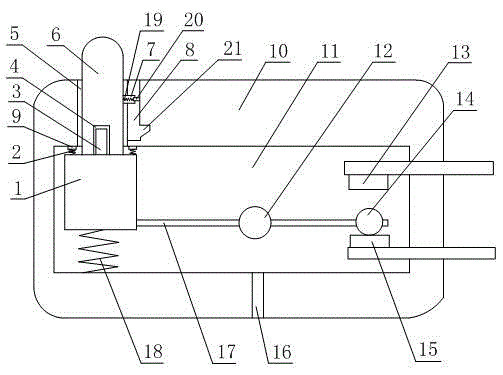

[0011] like figure 1 As shown in the figure, the control switch capable of increasing the operational safety includes a housing 10 with a cavity 11 provided therein, a through hole 5 is provided on the housing 10, and the through hole 5 communicates with the interior of the housing 10, and the cavity 11 There is a limit bump 1 in the middle, a push button 6 is fixed on the top of the limit bump 1, and the push button 6 can rotate along its own axis on the limit bump 1, and the push button 6 passes through the through hole. Hole 5, the side wall of the through hole 5 is concave to form a strip groove 8, and the strip groove 8 is communicated with the top of the through hole 5, the bottom surface of the strip groove 8 is concave to form a clamping groove 21, and the clamping groove 21 The depth is greater than the depth of the strip groove 8, and a smooth connection is formed between the side wall of the clamping groove 21 and the strip groove 8. The side wall of the push button...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com