Method of detecting casein in dairy products by using tetraphenylethylene derivatives

A technology of tetraphenylene and derivatives, applied in chemiluminescence/bioluminescence, analysis by chemical reaction of materials, etc., can solve the problems of poor specificity, low sensitivity, easy interference of milk protein determination methods, etc., to prevent the effect of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

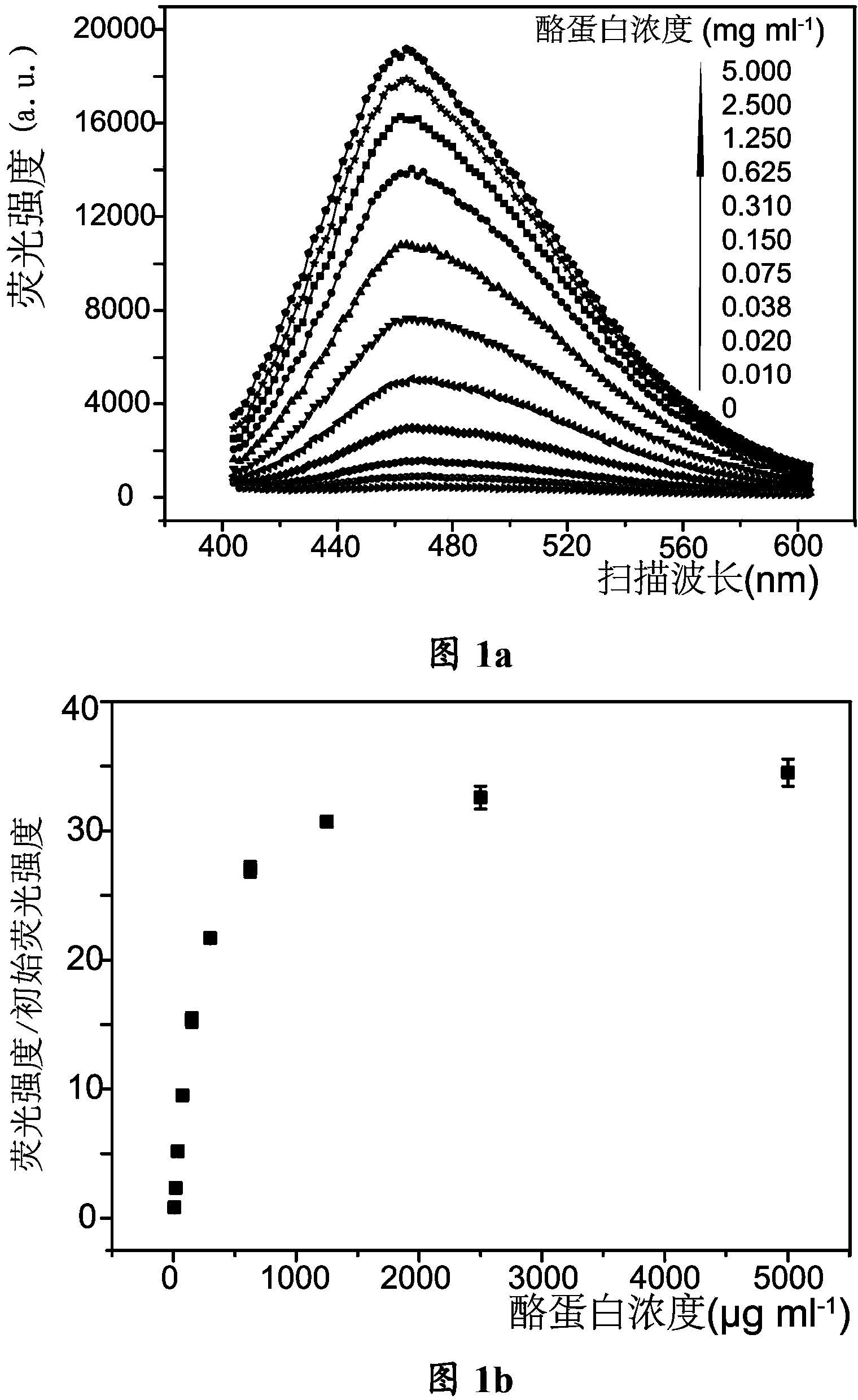

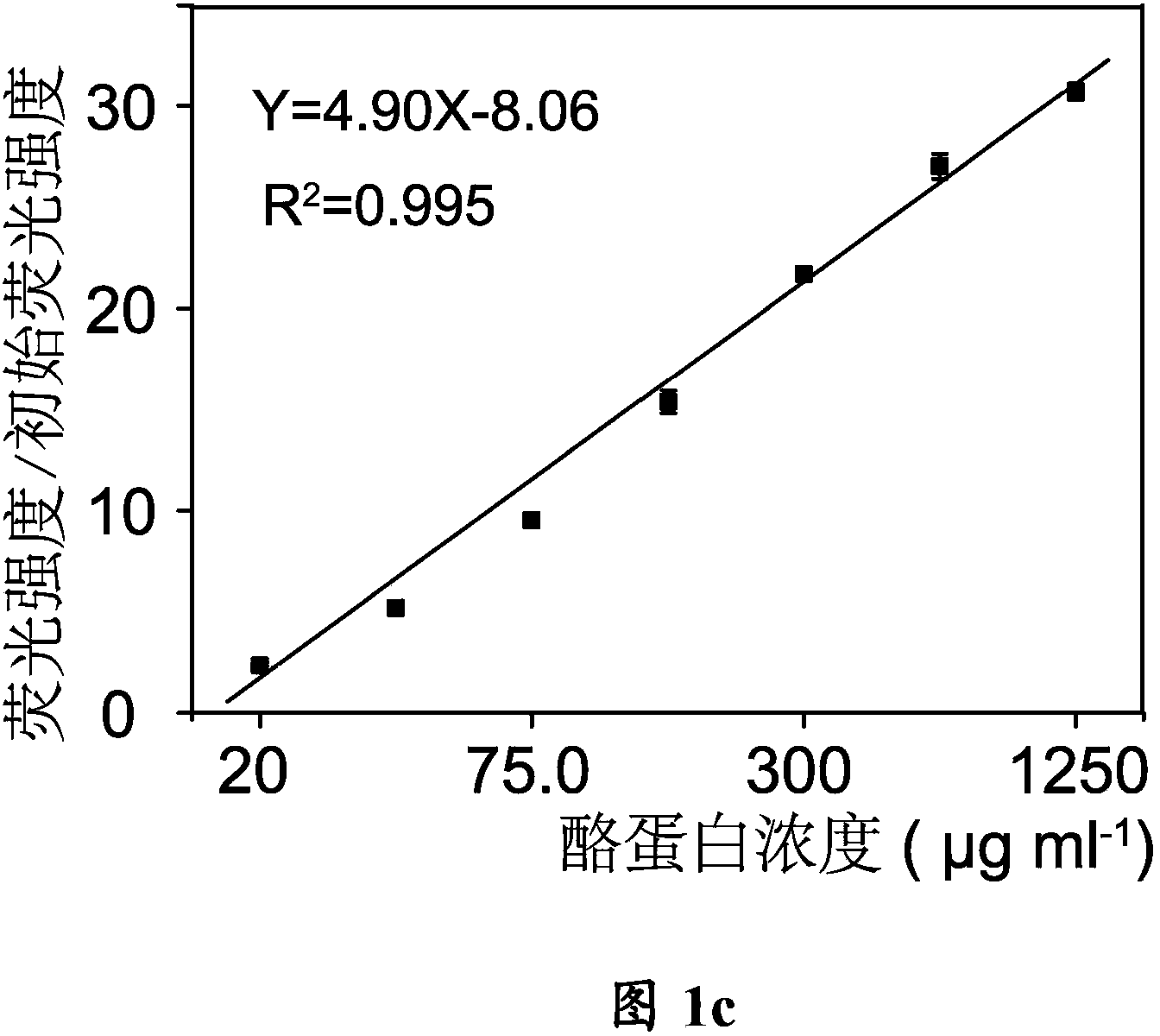

[0055] Preparation of standard curve: Mix 100 μl of casein solution with concentrations of 5, 2.5, 1.25, 0.625, 0.3125, and 0 mg / ml with 100 μl of 1 μM BSPOTPE molecules, excite at 370 nm, emit at 450 nm to measure fluorescence, and make a standard for fluorescence and concentration changes curve. The result is shown in Figure 1.

Embodiment 2

[0057] The test sample is whole milk powder. Take 5 mg of whole milk powder 1, whole milk powder 2, whole milk powder 3 and whole milk powder 4 respectively, and dissolve them in 1 ml of water respectively to make a 5 mg / ml milk solution, and put the solution in a centrifuge at 2000rpm Centrifuge for 10 minutes to skim off the fat on the surface of the solution. The pH of the lower layer solution was adjusted to 4.7 with 2M acetic acid, at this time the casein would precipitate, and it was centrifuged in a centrifuge at 5000rpm for 10 minutes to take out the precipitate. The precipitate was washed with ethanol and ether at a ratio of 1:1. Dissolve in 1 ml of water after washing. Mix 100 μl of casein solution with 100 μl of 1 μM BSPOTPE molecules, excite at 370 nm, and emit at 450 nm to measure fluorescence. The fluorescence value was compared with the standard curve to read out the casein content. The results are shown in Table 1 below.

[0058] Table 1 Comparison of the ...

Embodiment 3

[0061] The test sample is whole milk, which is Yili pure milk produced in China. Dilute 100 μl of milk in 1 ml of water, centrifuge the solution in a centrifuge at 2000 rpm for 10 minutes to skim off the fat on the surface of the solution. The pH of the lower layer solution was adjusted to 4.7 with 2M acetic acid, at this time the casein would precipitate, and it was centrifuged in a centrifuge at 5000rpm for 10 minutes to take out the precipitate. The precipitate was washed with ethanol and ether at a ratio of 1:1. Dissolve in 1 ml of water after washing. Mix 100 μl of casein solution with 100 μl of 1 μM BSPOTPE molecules, excite at 370 nm, and emit at 450 nm to measure fluorescence. The fluorescence value was compared with the standard curve to read out the casein content. It can be obtained that the casein content per 100ml of whole milk is 2.0 grams. The label of the packaging bag is that the protein content of 100ml of milk is 3.0g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com