Cooling device for annular cooling machine and annular cooling machine

A technology of annular cooler and cooling device, applied in the field of material cooling device, can solve problems such as powder leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

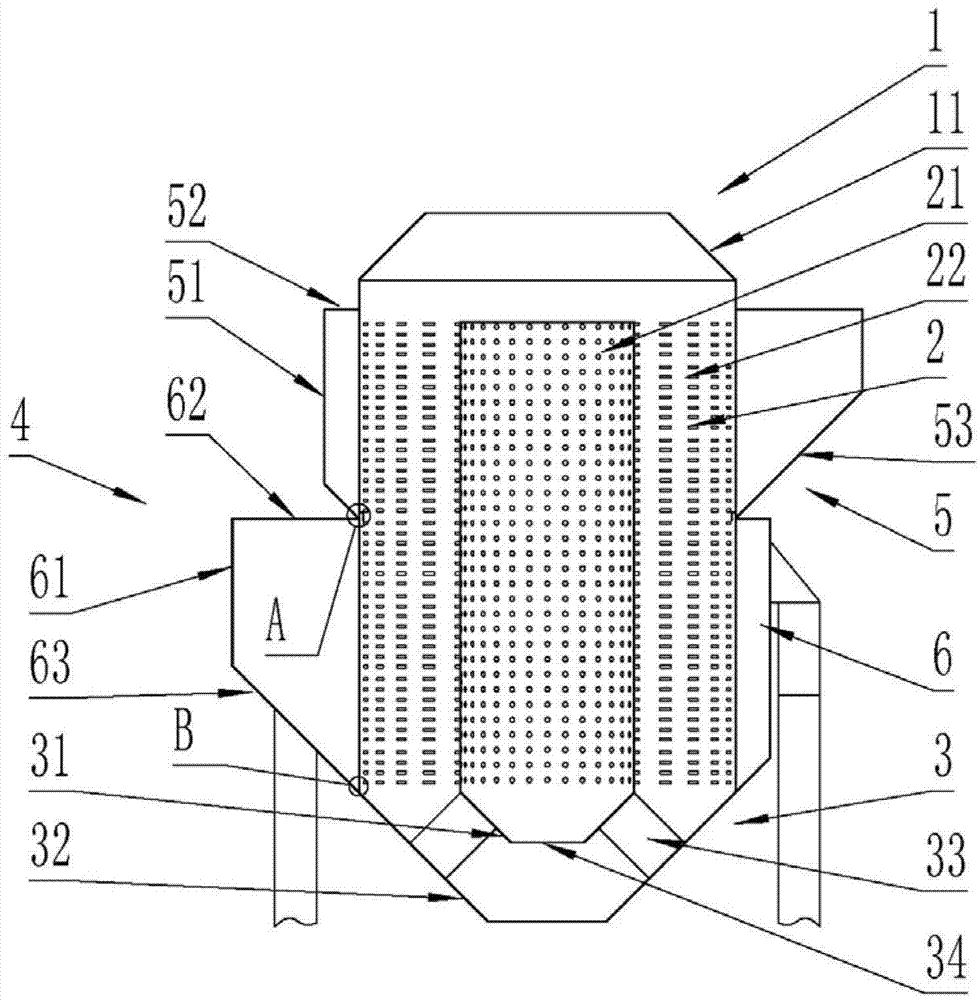

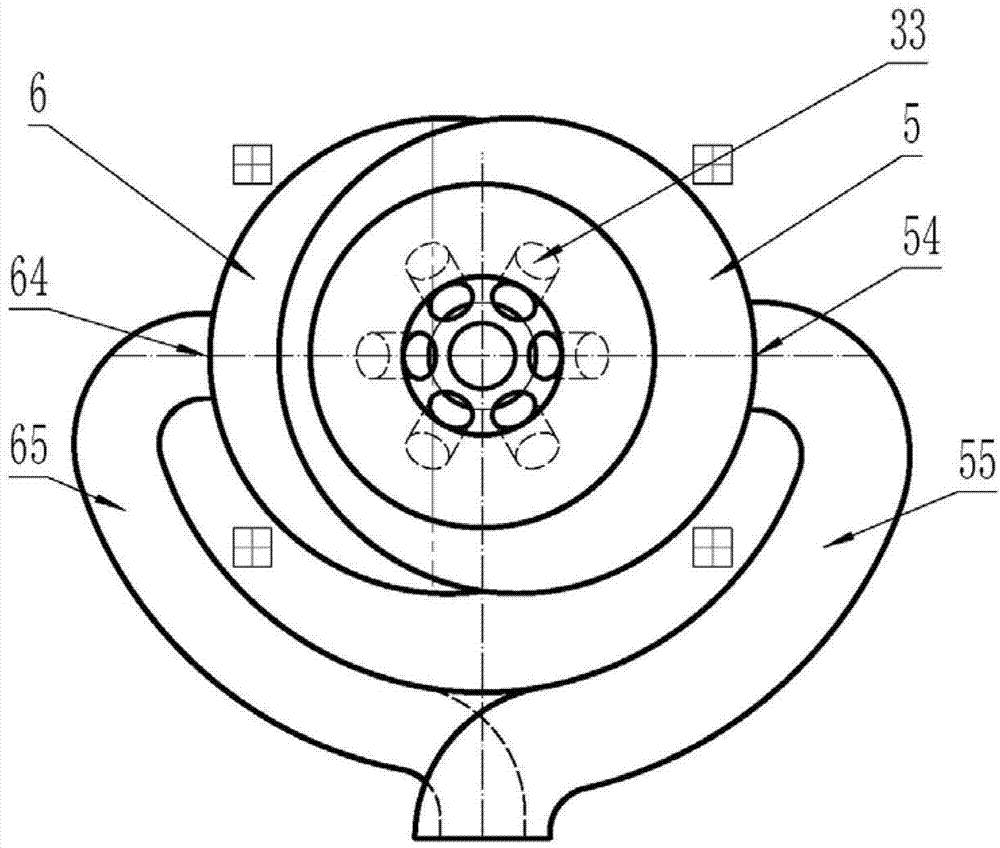

[0041] reference figure 1 with figure 2 , Respectively are the structural schematic diagram and the top view of the annular cooler with cooling device of the present invention. The annular cooler includes a feeding device 1, an annular material channel 2, a discharging device 3 and a cooling device 4. The material enters from the feeding device 1, and is discharged from the discharging device 3 after passing through the annular material channel 2. The cooling device 4 is used for Cool the material in the annular material channel 2.

[0042] The feeding device 1 includes a hollow structure and the top sealed end of the inner cylinder. The upper end of the hollow structure 11 is the upper open end for material entry, the lower end of the hollow structure and the top end of the outer cylinder 22 are along the circumferential direction. Fixed connection. The sealed end of the top of the inner cylinder 21 can be a flat structure; or a conical side surface of a conical structure, whe...

Embodiment 2

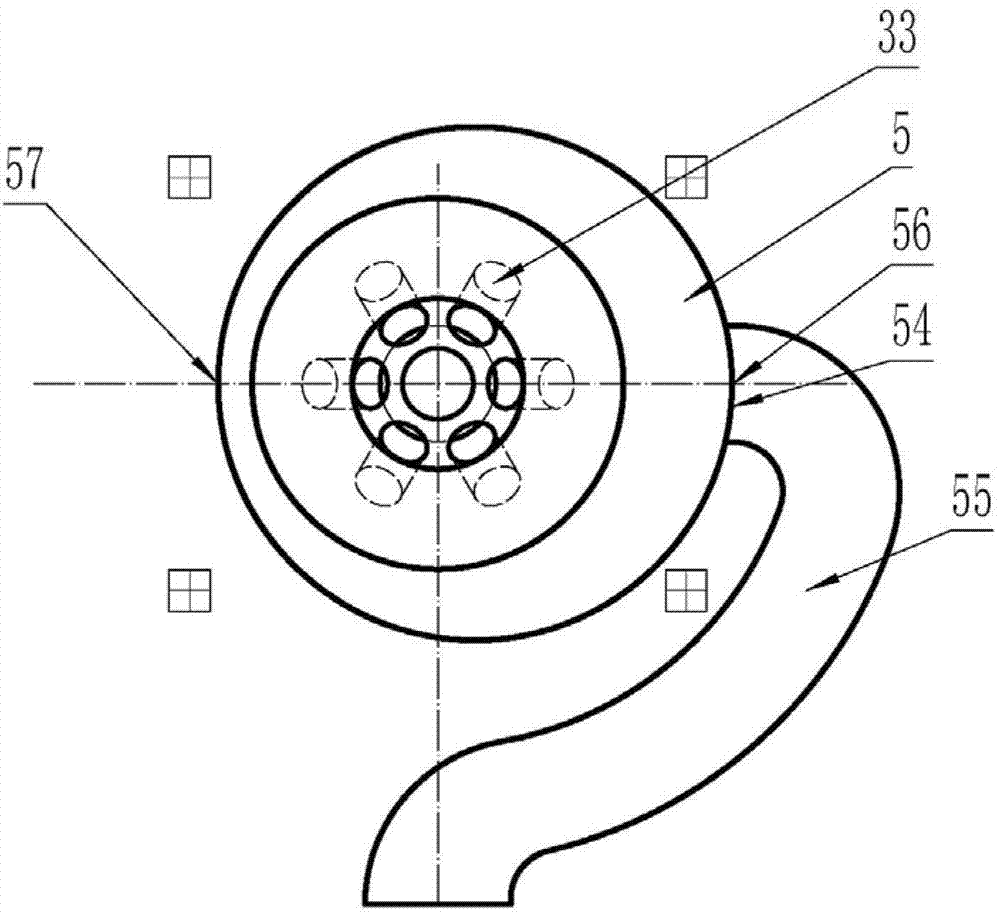

[0055] The difference between the second embodiment and the first embodiment is that the sealed suction chamber at the upper part of the outer cylinder 22 is replaced by a sealed air supply chamber. The sealed air supply chamber is an annular closed space covering the ventilation holes of the outer cylinder. The air chamber is provided with an air inlet, which is connected with a cold air source (air cooler). The cold air source enters the annular material passage through the air inlet and the vent on the outer cylinder. The hot air after heat exchange with the material can pass through the upper part of the annular material passage. The opening is returned to the upper level device (for example: rotary kiln) for reuse, the generated dust can also be returned to the upper level device (for example: rotary kiln) with the hot air, and the dust entering the inner cavity of the inner cylinder 21 can be opened from the bottom of the inner lower hopper End 34 is discharged.

Embodiment 3

[0057] The difference between Embodiment 3 and Embodiments 1 and 2 is that for each sealed suction chamber, more than one suction opening can be provided, and each suction opening is connected with a suction fan to draw air from different suction openings. Preferably, for a sealed suction chamber, a plurality of suction openings are evenly distributed along the circumferential direction to ensure uniform cooling of the material. Another preference is that all the air extraction openings of each sealed air extraction chamber are evenly distributed in the circumferential direction, which also ensures uniform cooling of the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com