Axially sealed vacuum insulation ultralow-temperature rotating joint

An axial sealing, vacuum insulation technology, applied in the direction of pipe/pipe joint/pipe fitting, heat preservation, adjustable connection, etc., can solve the problems of cumbersome operation, difficult rotation, etc., to overcome leakage, no need for nitrogen protection, to overcome radial runout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

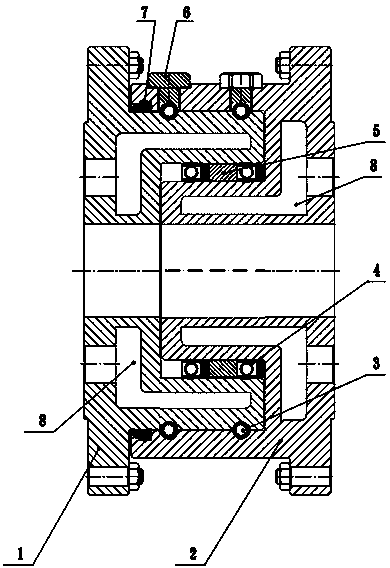

[0011] Such as figure 1 As shown, the axially sealed vacuum insulated ultra-low temperature rotary joint of the present invention includes an inner ring 1 , an outer ring 2 , rolling elements 3 , an axial sealing ring 4 , an isolation ring 5 , ring blocking bolts 6 , and a dustproof sealing ring 7 .

[0012] The inner ring 1 and the outer ring 2 are connected by rolling elements 3 and rotate with each other. The axial sealing ring 4 and the spacer ring 5 are installed between the inner ring 1 and the outer ring 2 and rotate freely with the inner and outer rings. The dustproof sealing ring 7 is installed on the The extreme end where inner ring 1 and outer ring 2 join. The inner and outer rings are connected with their respective raceways through steel balls and rotate freely. The sealing ring realizes the sealing of the inner and outer rings of the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com