Ultrahigh-strength prestressed steel wire

A prestressed steel wire, ultra-high strength technology, applied in the direction of building reinforcements, structural elements, building components, etc., can solve the problems of time-consuming connection and disassembly, loss of strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

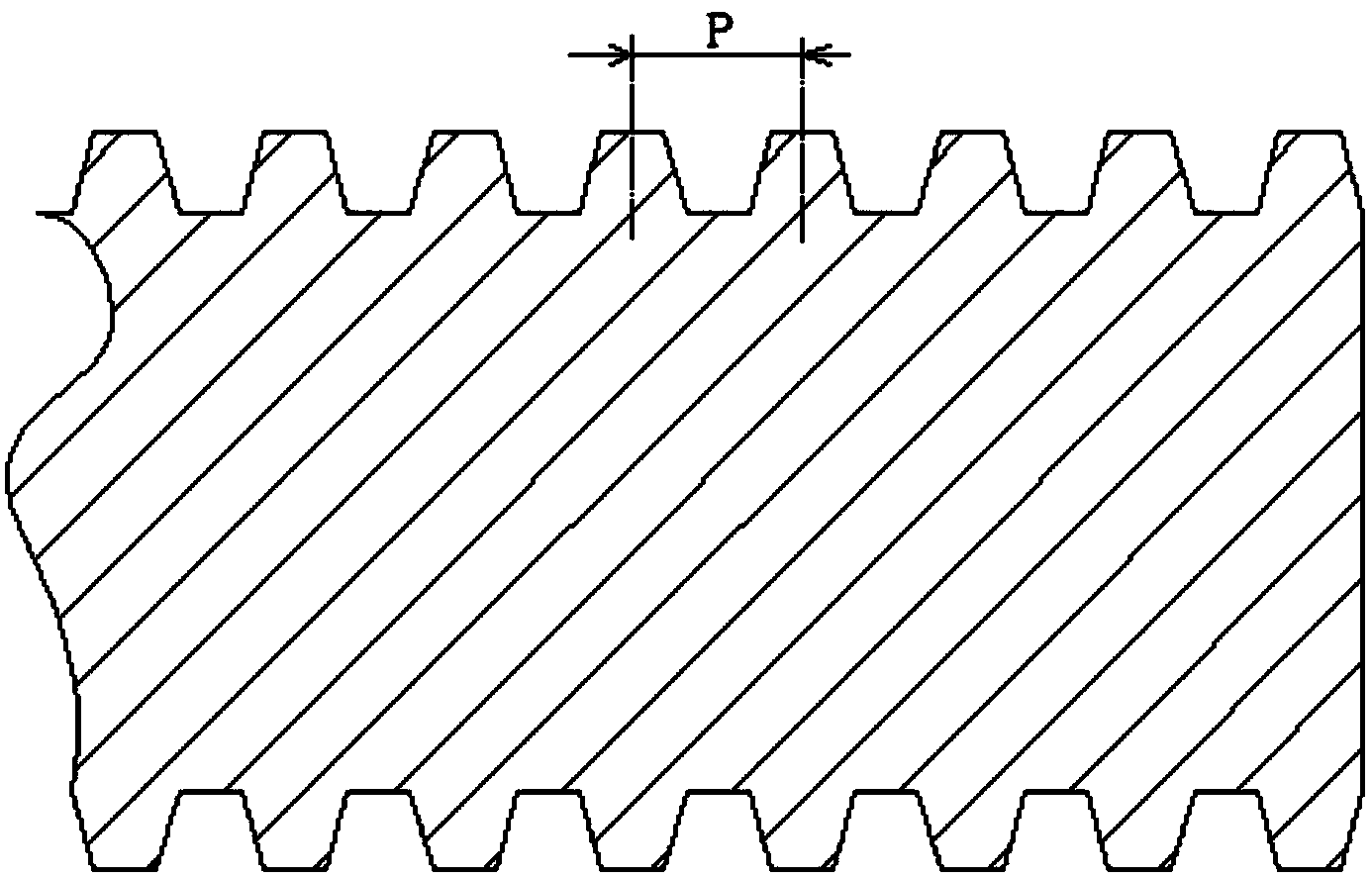

[0020] Such as figure 1 , figure 2 As shown, the present invention includes a 2.3m-long spiral rib steel wire with a diameter of 8mm, one end of the steel wire has an external thread, the length of the external thread is 10mm, and the external thread is 2 threads, each The widths of the threads are equal, the spacing is equal, and the axial included angle is consistent with the radial rise angle. The pitch P of the external threads, that is, the axial distance between each thread is 0.5 mm. The distance between the middle diameter of the external thread and the outer diameter or inner diameter is 0.2 mm. The tooth form of the external thread is a triangular thread.

Embodiment 2

[0022] Such as figure 1 , image 3 As shown, the present invention includes a 3m-long spiral rib steel wire with a diameter of 30mm, one or both ends of the steel wire are provided with external threads, the length of the external thread is 65mm, and the external thread is 4 threads , The width of each thread is equal, the spacing is equal, and the axial angle is the same as the radial angle. The pitch P of the external thread is 3 mm. The distance between the middle diameter of the external thread and the outer diameter or inner diameter is 2.5 mm. The tooth profile of the external thread is a trapezoidal thread.

Embodiment 3

[0024] Such as figure 1 , Figure 4 As shown, the present invention includes a 2.5m long spiral rib steel wire with a diameter of 20mm, one or both ends of the steel wire are provided with external threads, the length of the external thread is 40mm, and the external thread is 3 threads. For thread, the width of each thread is equal, the spacing is equal, and the axial included angle is consistent with the radial rise angle. The pitch P of the external thread is 2 mm. The distance between the middle diameter of the external thread and the outer diameter or inner diameter is 1.5 mm. The tooth profile of the external thread is an R arc thread.

[0025] This technical solution adopts the special process of multiple threads to reduce the strength loss in the threaded area, improve the durability of concrete products, especially the high-speed rail ballastless track slab, increase the lead of the thread, improve the efficiency of installation and disassembly, and upgrade the existing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com