Vulcanized rubber or thermoplastic rubber and metal adhesive

A technology of thermoplastic rubber and vulcanized rubber, which is applied in the field of vulcanized rubber or thermoplastic rubber and metal adhesives, and can solve problems such as weak interface layer and product damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

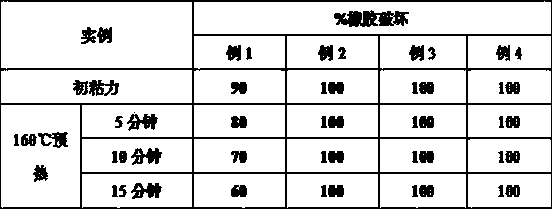

Examples

Embodiment Construction

[0034] The foregoing description and the following examples are intended to disclose and illustrate the present invention, and the specific amounts and combinations of the ingredients described herein are not intended to limit the scope of the present invention defined by the claims.

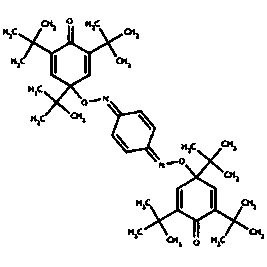

[0035] The p-benzoquinonedioxime-bis(1,3,5-tri-tert-butyl-4-oxocyclohexyl-2,5-dienyl)-ether of the present invention was prepared as follows:

[0036]

[0037] p-Benzoquinonedioxime-bis(1,3,5-tri-tert-butyl-4-oxocyclohexyl-2,5-dienyl)-ether

[0038] 90 g of 2,4,6-tri-tert-butyl-phenoxy radical was added to the benzene solution under the condition of flowing sufficient argon gas, and then 52 g of p-dinitrosobenzene was added. The reaction temperature was kept at about 20 °C until the color of the solution changed from light green to yellow. Then the unreacted p-dinitrosobenzene and benzene were distilled off at 30°C, and the residue was recrystallized with ethanol. 75 g of p-benzoquinonediox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com