Synthetic method of 2-mercaptobenzimidazole allyl sulfide

A technology of mercaptobenzimidazolene propylene sulfide and mercaptobenzimidazole, which is applied in the fields of iron and steel, petrochemical, electric power and construction, and petroleum, can solve the problems of high production cost and unfavorable industrialization, and achieve high yield and synthetic reaction The effect of mild conditions and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

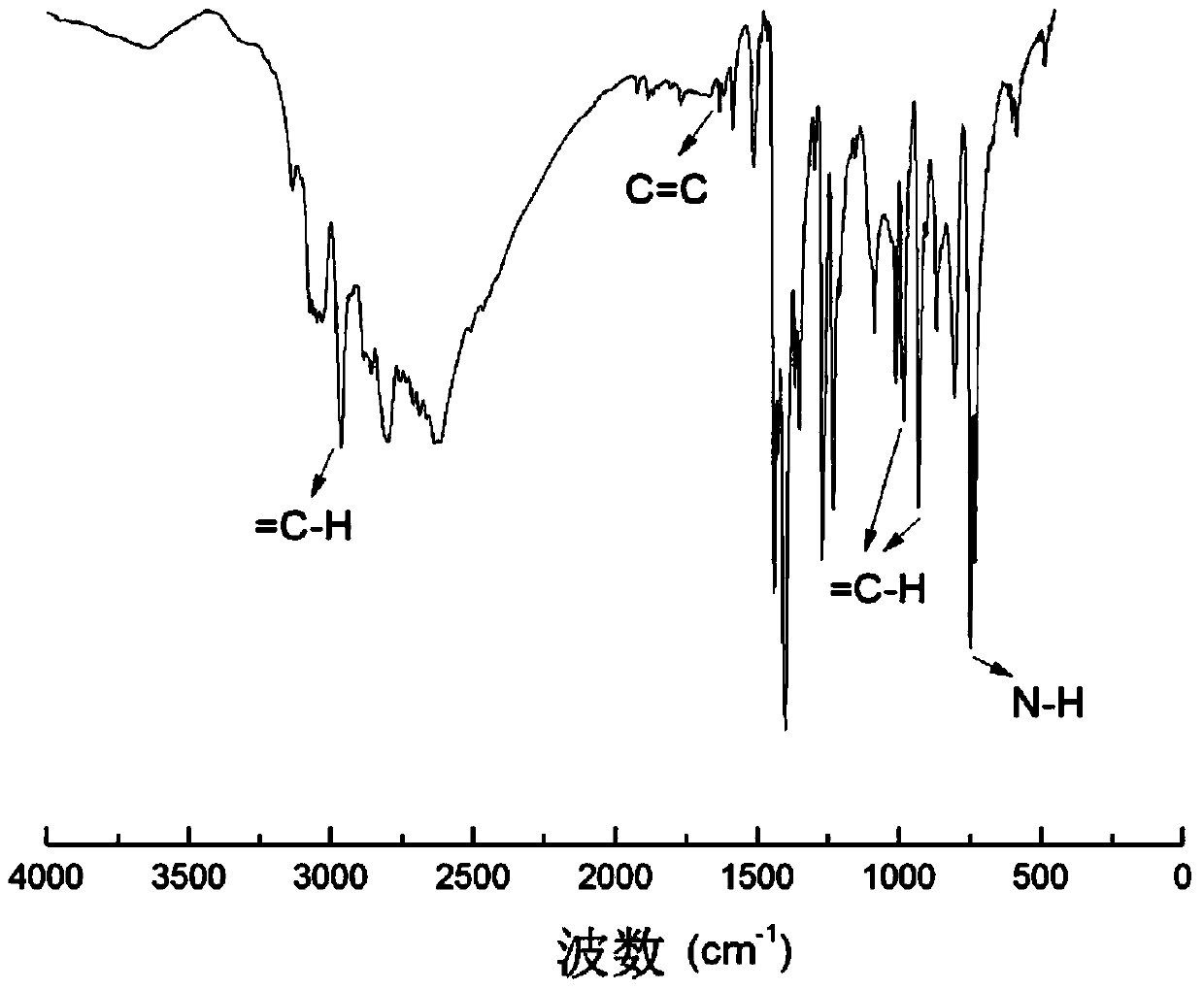

Image

Examples

Embodiment 1

[0022] 1) Under the protection of nitrogen, add 1 part (2.4g) of 2-mercaptobenzimidazole and 4 (9.6g) parts of acetone into the reaction kettle, and magnetically stir until 2-mercaptobenzimidazole Fully dissolve evenly.

[0023] 2) After dissolving evenly, add 5 parts (12g) of potassium hydroxide solution with a mass fraction of 26% into the reaction kettle, then quickly add 0.2 parts (0.48g) of tetrabutylammonium bromide, and stir magnetically to make it uniform.

[0024] 3) Add 1 part (2.4g) of allyl chloride dropwise and keep stirring at room temperature for 3h.

[0025] 4) Collect the product after filtration and drying, and further recrystallize and purify with acetone to obtain the product.

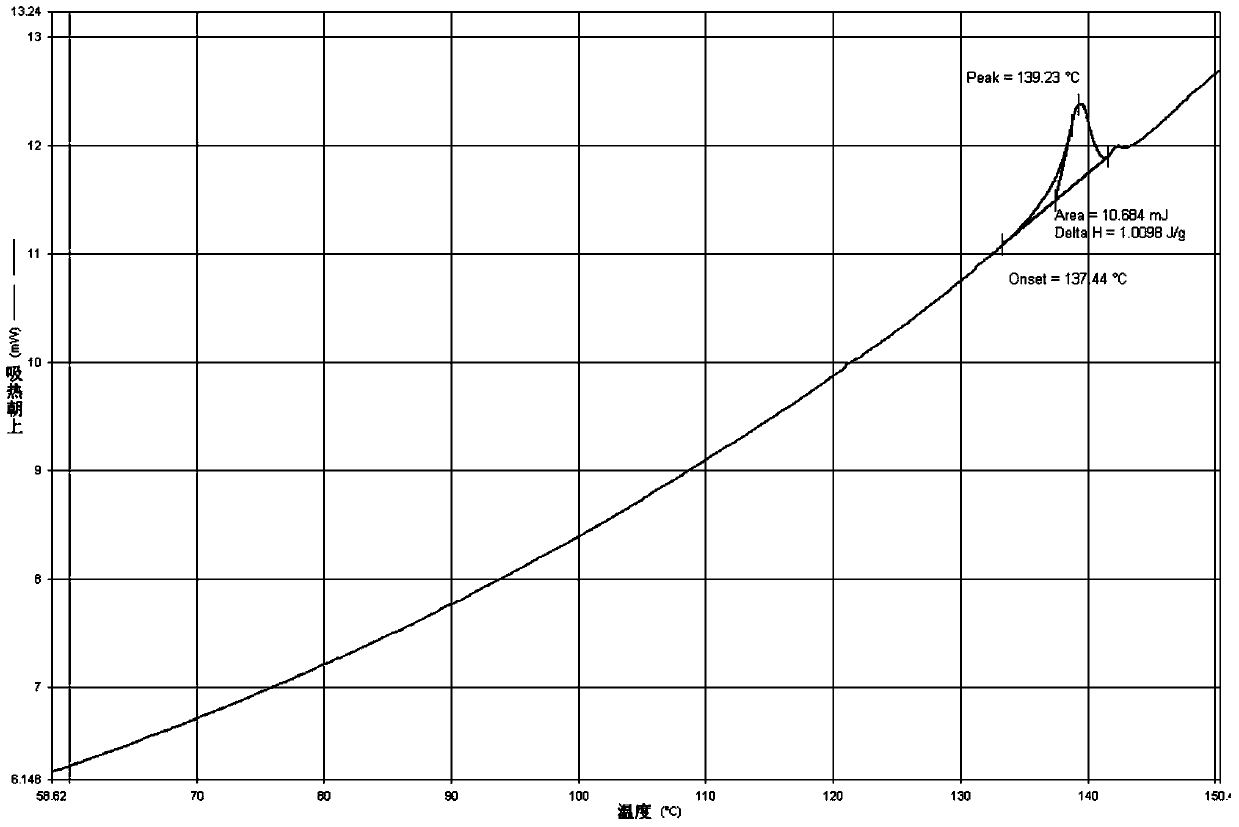

[0026] The prepared 2-mercaptobenzoallyl sulfide is a pale yellow solid crystal with a melting point between 125°C and 131°C.

Embodiment 2

[0028] 1) Under the protection of nitrogen, add 1 part (2.4g) of 2-mercaptobenzimidazole and 4 parts (9.6g) of tetrahydrofuran into the reaction kettle, and magnetically stir until 2-mercaptobenzimidazole Fully dissolve evenly.

[0029] 2) After dissolving evenly, add 5 parts (15g) of potassium hydroxide solution with a mass fraction of 26% into the reaction kettle, then quickly add 0.2 parts (0.48) of tetrabutylammonium hydroxide, and stir magnetically to make it uniform.

[0030] 3) Add 1 part (2.4g) of allyl bromide dropwise, and keep stirring at room temperature for 3h.

[0031] 4) Collect the product after filtration and drying, and further recrystallize and purify with acetone to obtain the product.

[0032] The prepared 2-mercaptobenzoallyl sulfide is a pale yellow solid crystal with a melting point between 125°C and 131°C.

Embodiment 3

[0034] 1) Under the protection of nitrogen, add 1.25 parts (3g) of 2-mercaptobenzimidazole and 5 parts (12g) of acetone into the reaction kettle, and stir magnetically until 2-mercaptobenzimidazole is fully dissolved uniform.

[0035] 2) After dissolving evenly, add 4 parts (9.6g) of potassium hydroxide solution with a mass fraction of 26% into the reaction kettle, then quickly add 0.1 part (0.24g) of tetrabutylammonium hydroxide, and stir magnetically to make it uniform.

[0036] 3) Add 2 parts (4.8g) of allyl chloride dropwise and keep stirring at room temperature for 3h.

[0037] 4) Collect the product after filtration and drying, and further recrystallize and purify with acetone to obtain the product.

[0038] The prepared 2-mercaptobenzoallyl sulfide is a pale yellow solid crystal with a melting point between 125°C and 131°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com