Burning-resistant conveyor belt

A conveyor belt, integrated technology, used in the field of material conveyor belts, can solve the problems of surface peeling, reducing the strength of the tape, damage to the skeleton material, etc., to achieve excellent burning resistance, improve flexural resistance, and ensure the effect of normal use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

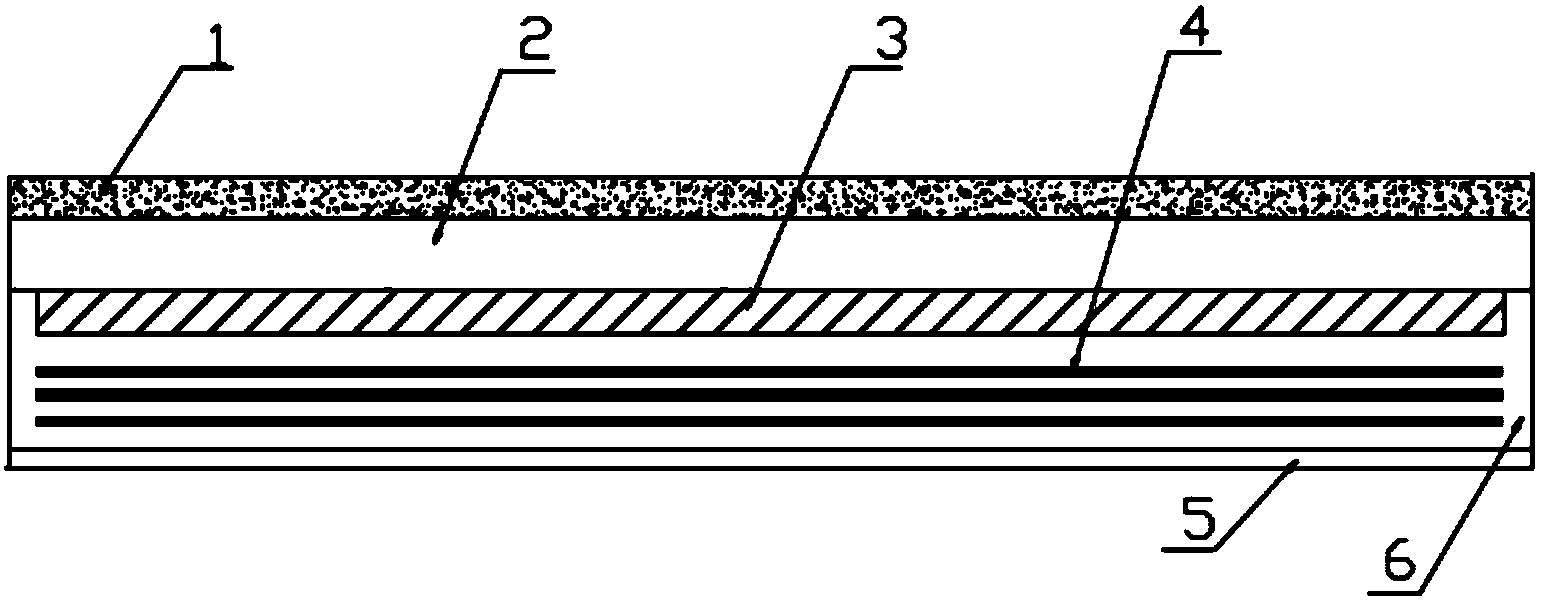

[0017] Such as figure 1 As shown, a burning-resistant conveyor belt has a cross-sectional structure; including a lower covering rubber layer 5 arranged from bottom to top, at least one layer of skeleton 4 and an upper covering layer 2, and the two sides of the skeleton layer 4 are provided with The edge glue 6 which is an integral structure with the lower covering adhesive layer 5 and the upper covering adhesive layer 2 is provided with a heat insulating layer 3 between the skeleton layer 4 and the upper covering adhesive layer 2, and the upper covering adhesive layer The top is provided with a burn-resistant layer 1.

[0018] The heat insulation layer 3 is glass fiber.

[0019] The burn-resistant layer 1 is made of styrene-butadiene material, and the thickness of the burn-resistant layer is 2 mm.

[0020] The skeleton layer 4 is three layers, and the layers are bonded with high-temperature-resistant styrene-butadiene glue.

[0021] The material of the skeleton layer is hea...

Embodiment 2

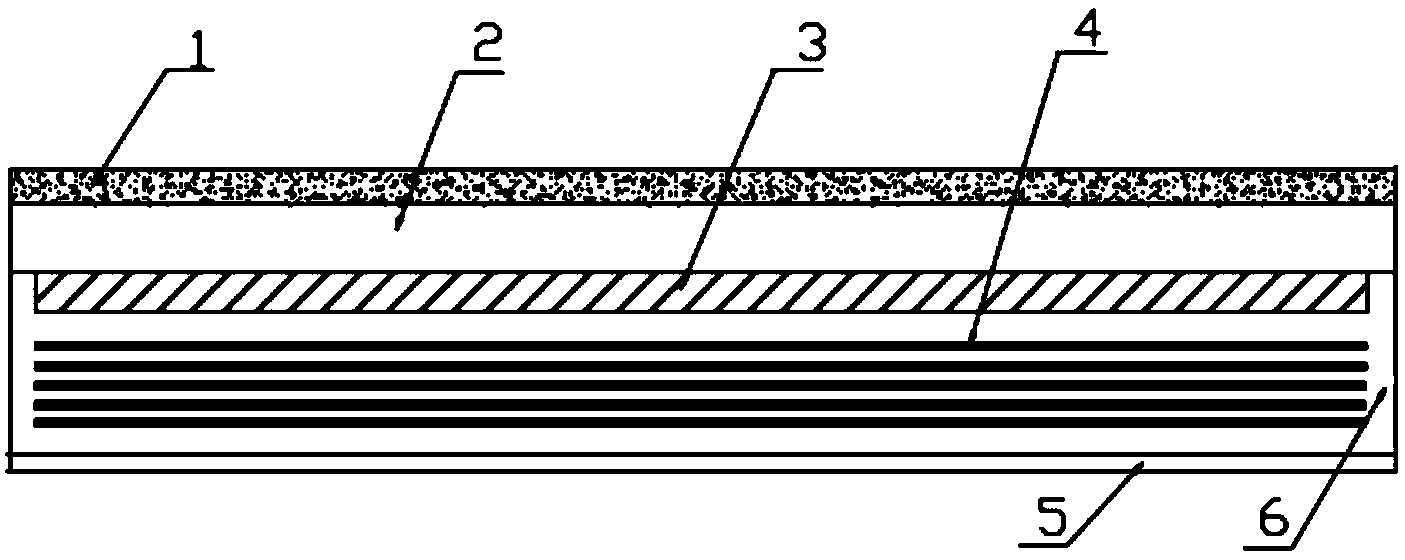

[0023] Such as figure 2 As shown, a burning-resistant conveyor belt has a cross-sectional structure; including a lower covering rubber layer 5 arranged from bottom to top, at least one skeleton layer and an upper covering layer 2, and the two sides of the skeleton layer 4 are provided with The lower covering adhesive layer 5 and the upper covering adhesive layer 2 form an edge adhesive 6 with an integrated structure, and a heat insulating layer 3 is provided between the skeleton layer 4 and the upper covering adhesive layer 2, and the upper covering adhesive layer A burn-resistant layer 1 is provided on it.

[0024] The heat insulating layer 3 is polyurethane.

[0025] The burn-resistant layer 1 is made of styrene-butadiene material, and the thickness of the burn-resistant layer is 6 mm.

[0026] The skeleton layer 4 is five layers, and the layers are bonded with high-temperature-resistant styrene-butadiene glue.

[0027] The material of the skeleton layer is modified glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com