Circulatory ink supply system of printing ink photogravure press

A gravure printing machine and ink circulation technology, which is applied to the general parts of printing machinery, printing machines, printing, etc., can solve the problems of ink loss due to proportion, printed product color difference, etc., to achieve the effect of reducing waste and realizing dynamic circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

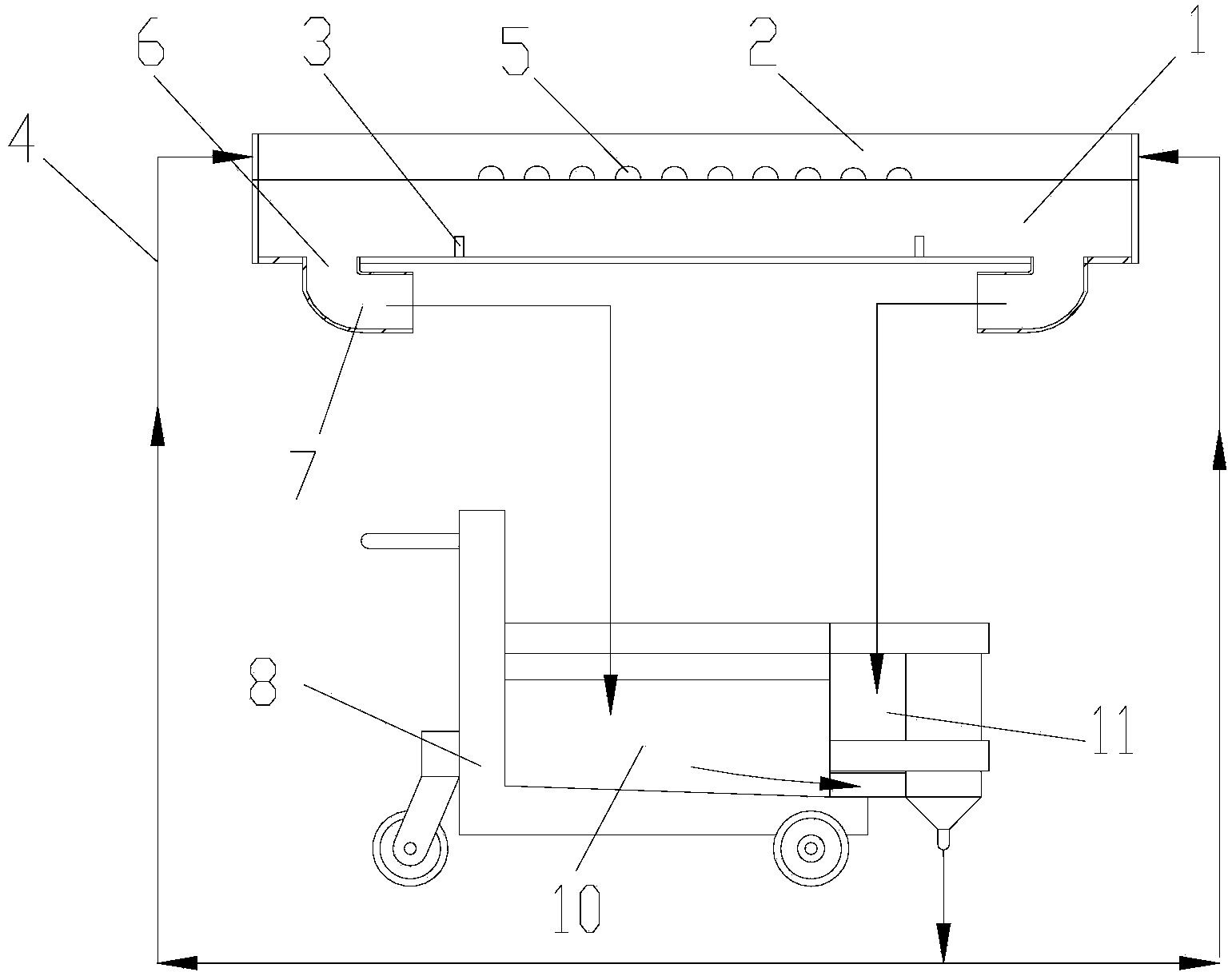

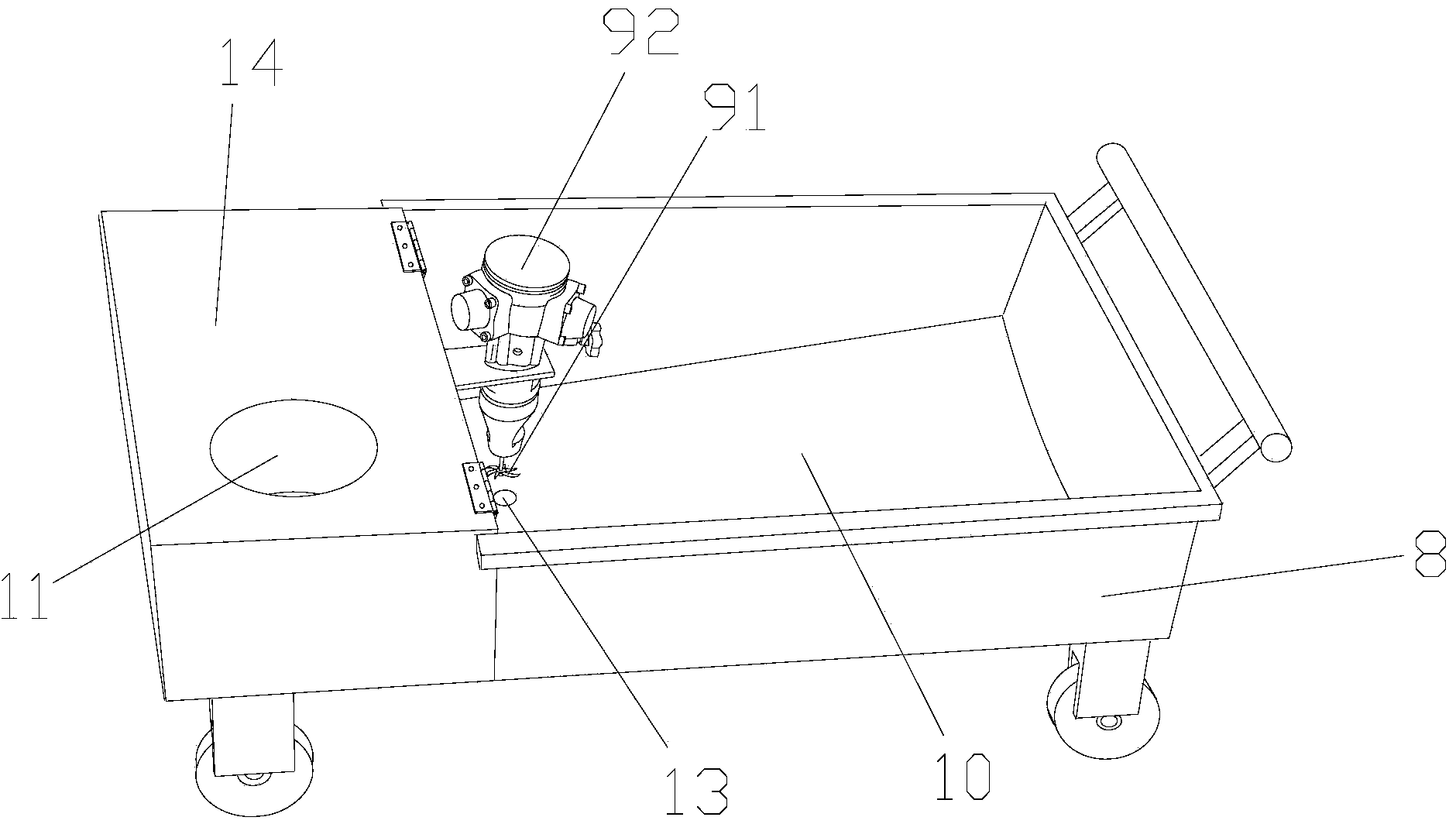

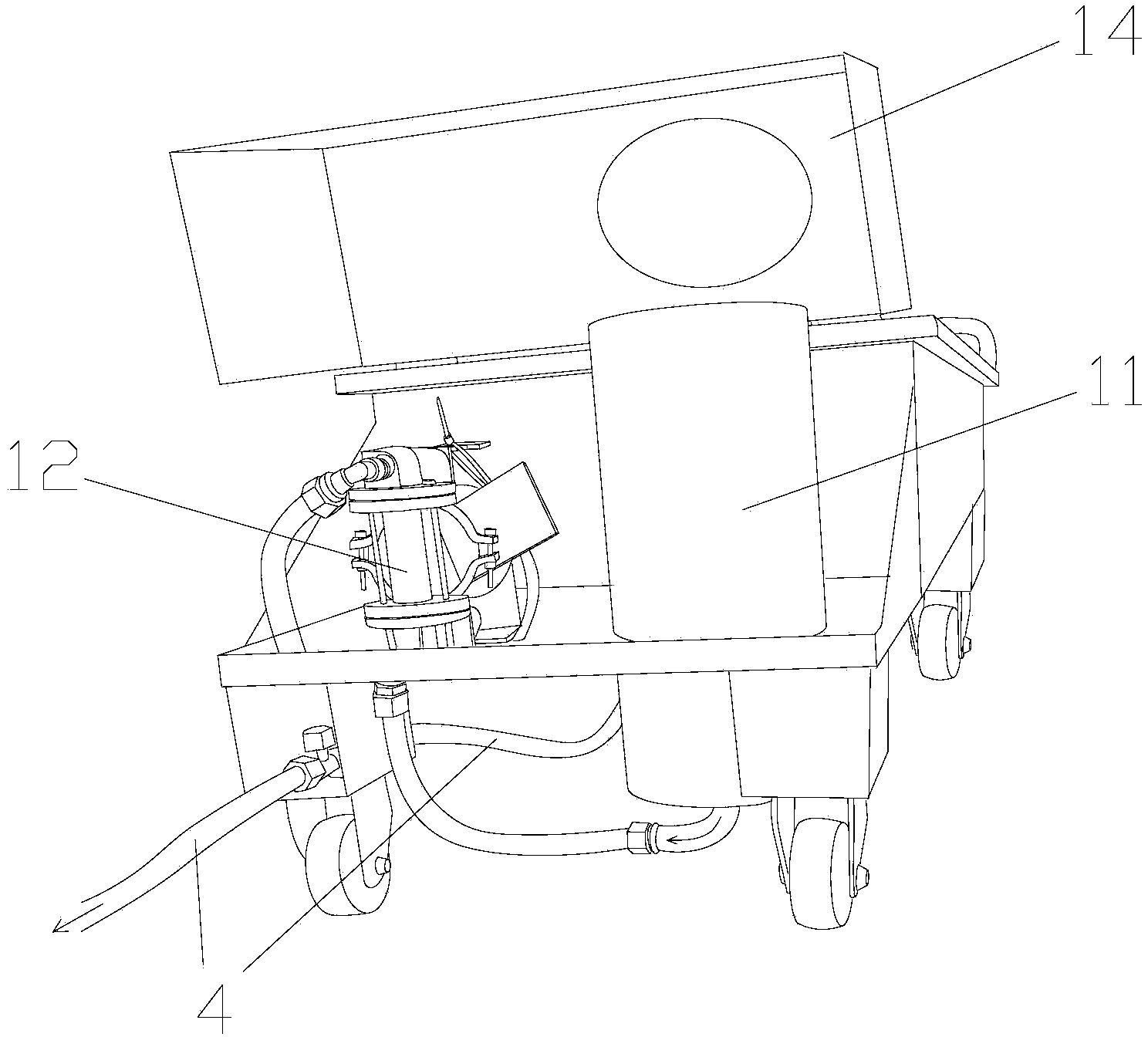

[0017] Examples, please refer to Figures 1 to 4 , a circulating ink supply system for an ink gravure printing machine, including an ink fountain 1 and an ink circulating vehicle 8 .

[0018] The ink fountain 1 is provided with an ink inlet pipe 2, and a group of through holes 5 are opened on the pipe wall of the ink inlet pipe 2. The diameter of the through holes 5 is 0.5 cm, and they are evenly arranged on the ink inlet pipe 2 every 10 cm. There is a backflow hole 6 on both sides of the inside of the ink fountain 1, and a set of overflow plates 3 for controlling the amount of ink are correspondingly arranged between the backflow holes 6. The backflow holes 6 pass through the ink outlet pipe 7 and the ink circulation vehicle 8 connected. Preferably, the ink inlet pipe 2 is a PPR pipe.

[0019] Ink circulation car 8 comprises a car body, the first ink tank 10 arranged on the car body, the stirring device installed on the side wall of the first ink tank 10, the second ink tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com