Device for sorting and recycling broken cigarette paper and tobacco powder in tobacco shreds

A technology for cigarette paper and shredded tobacco, which is applied in the direction of solid separation, separation of solid from solid by air flow, and filtering and sieving, which can solve the problems of increasing tobacco powder content, separating shredded cigarette paper, reducing the content of shredded cigarette paper, etc., to achieve Effects of reducing content and fines content, improving shredded tobacco quality, and improving cigarette quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

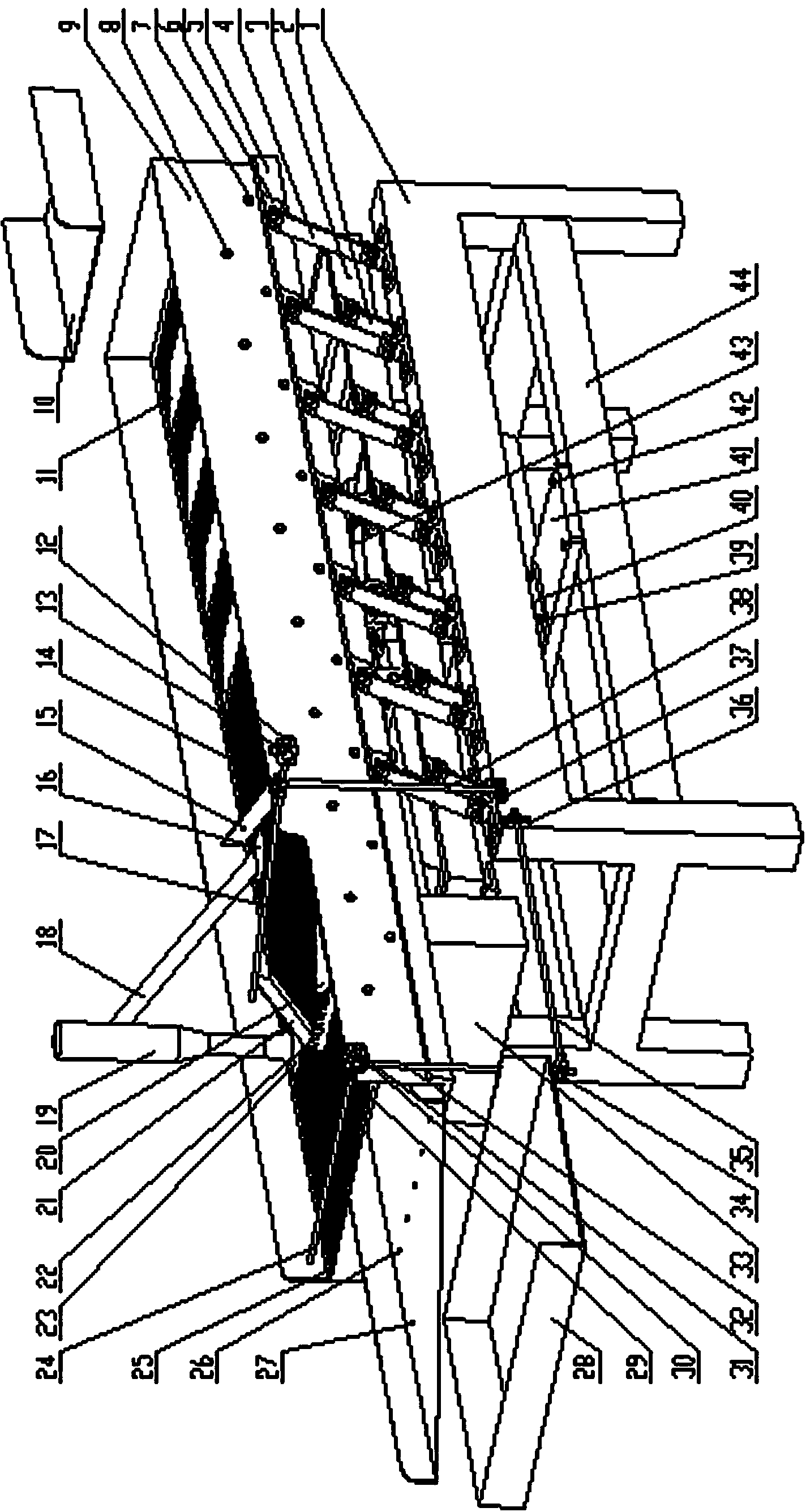

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings.

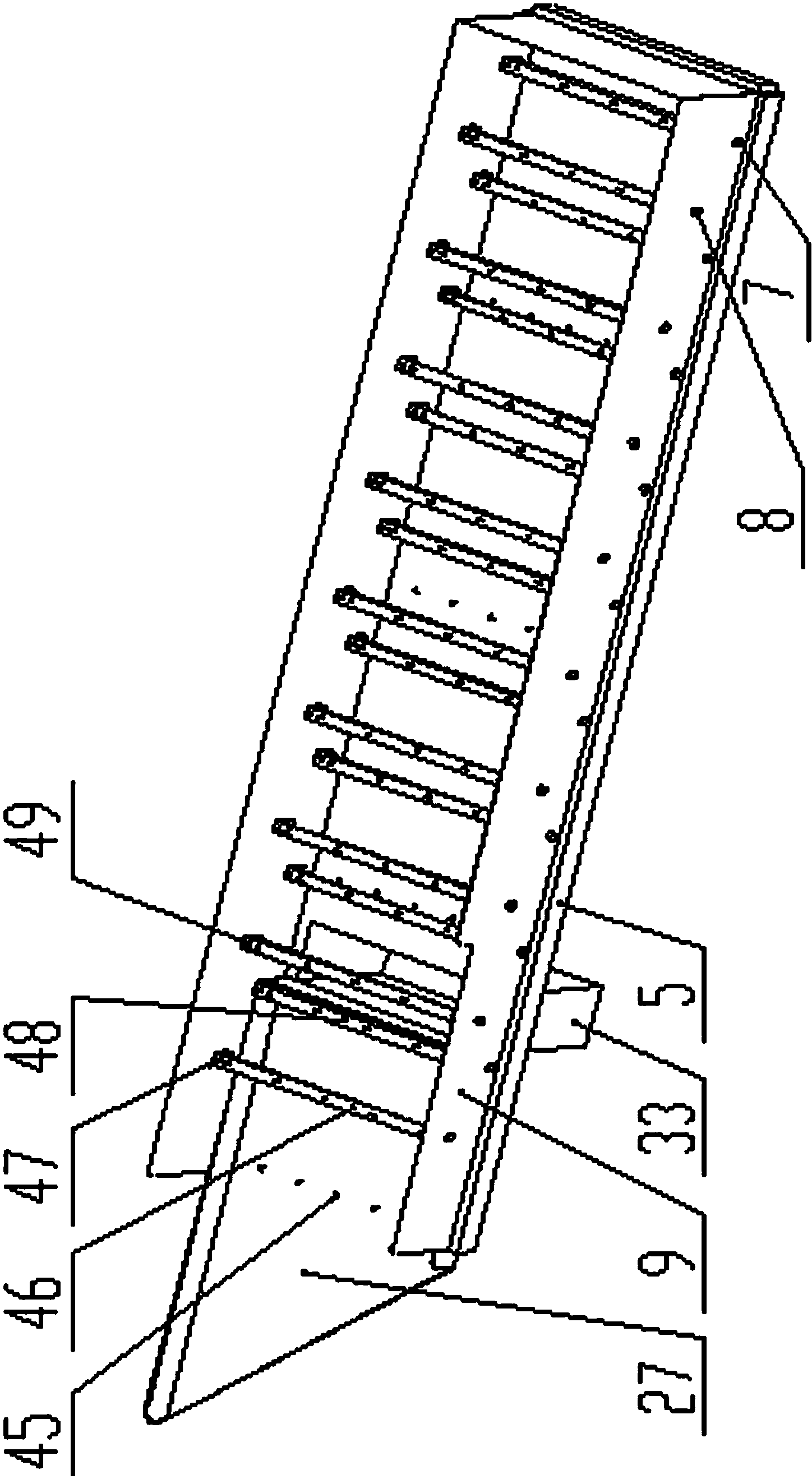

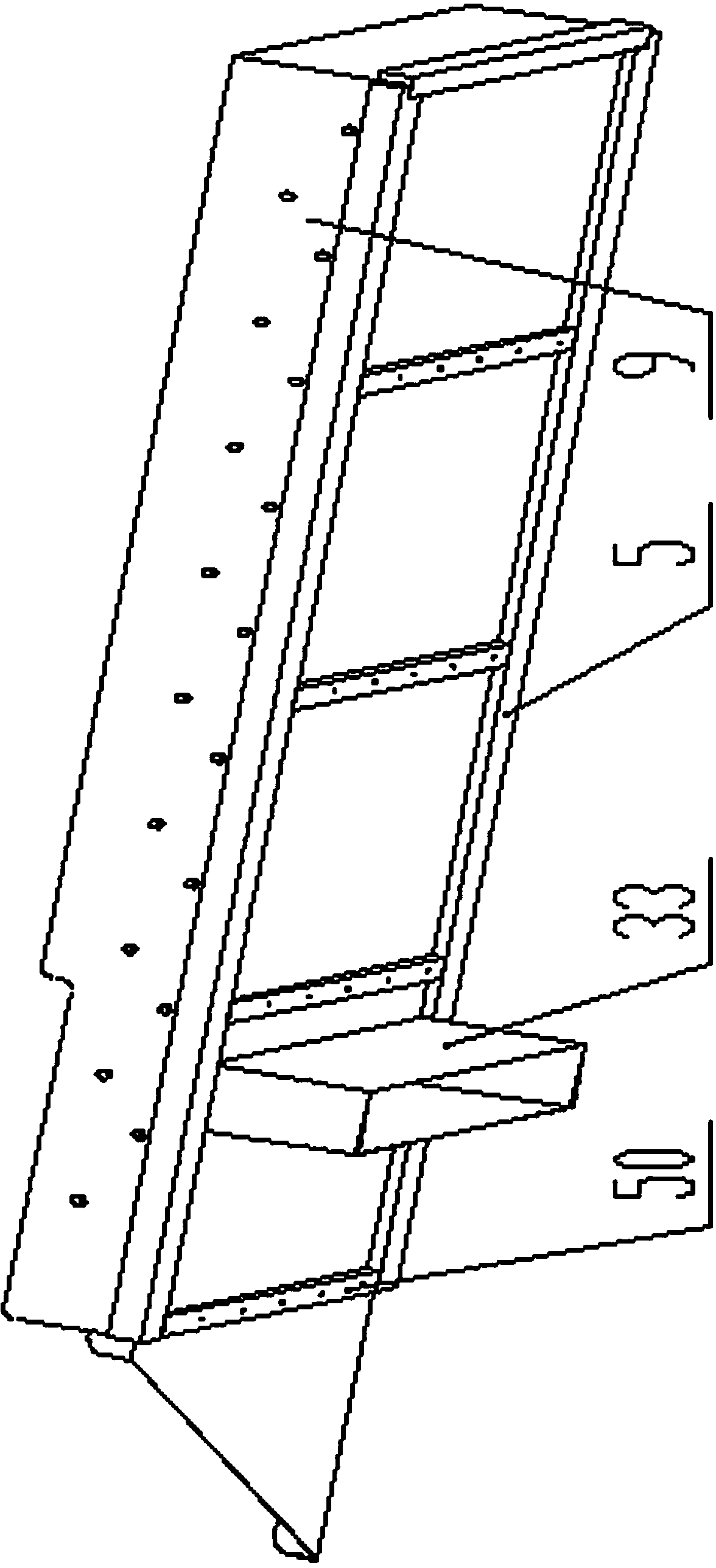

[0042] Design the vibrating trough frame 9 with baffles on three sides, and its width is 100~150mm larger than that of the feed trough. mm , length 3000~4000 mm , the bottom is designed with a smoke outlet, which is used to install the smoke outlet frame.

[0043] Design the screen trough frame, made of angle iron, the size is consistent with the bottom of the vibrating trough frame, several ribs are welded on the screen trough frame to improve its structural strength, the vibrating trough frame is installed on the ribs of the screen trough frame and the corners of the screen trough frame by screws On the iron, the discharge chute is installed in the vibration trough frame through screws and bolts, and the top of the discharge chute is the second layer of sieve plate.

[0044] Design the vibration trough frame ribs and install them in the vibration trough ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com