Ammonia purification system

A refining system and crude ammonia technology, applied in the field of ammonia refining system, can solve the problem of semiconductor function reduction and achieve the effect of suppressing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

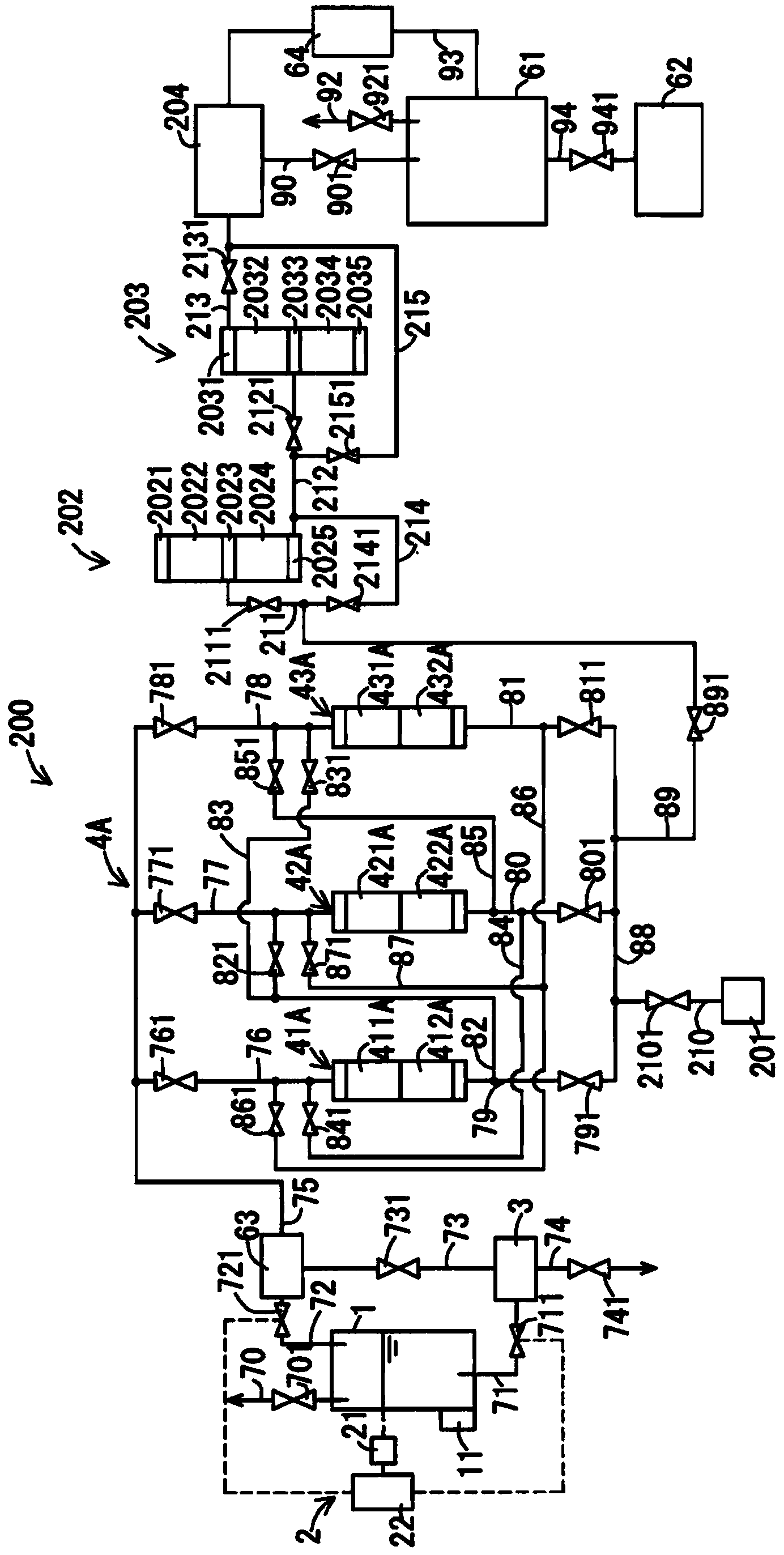

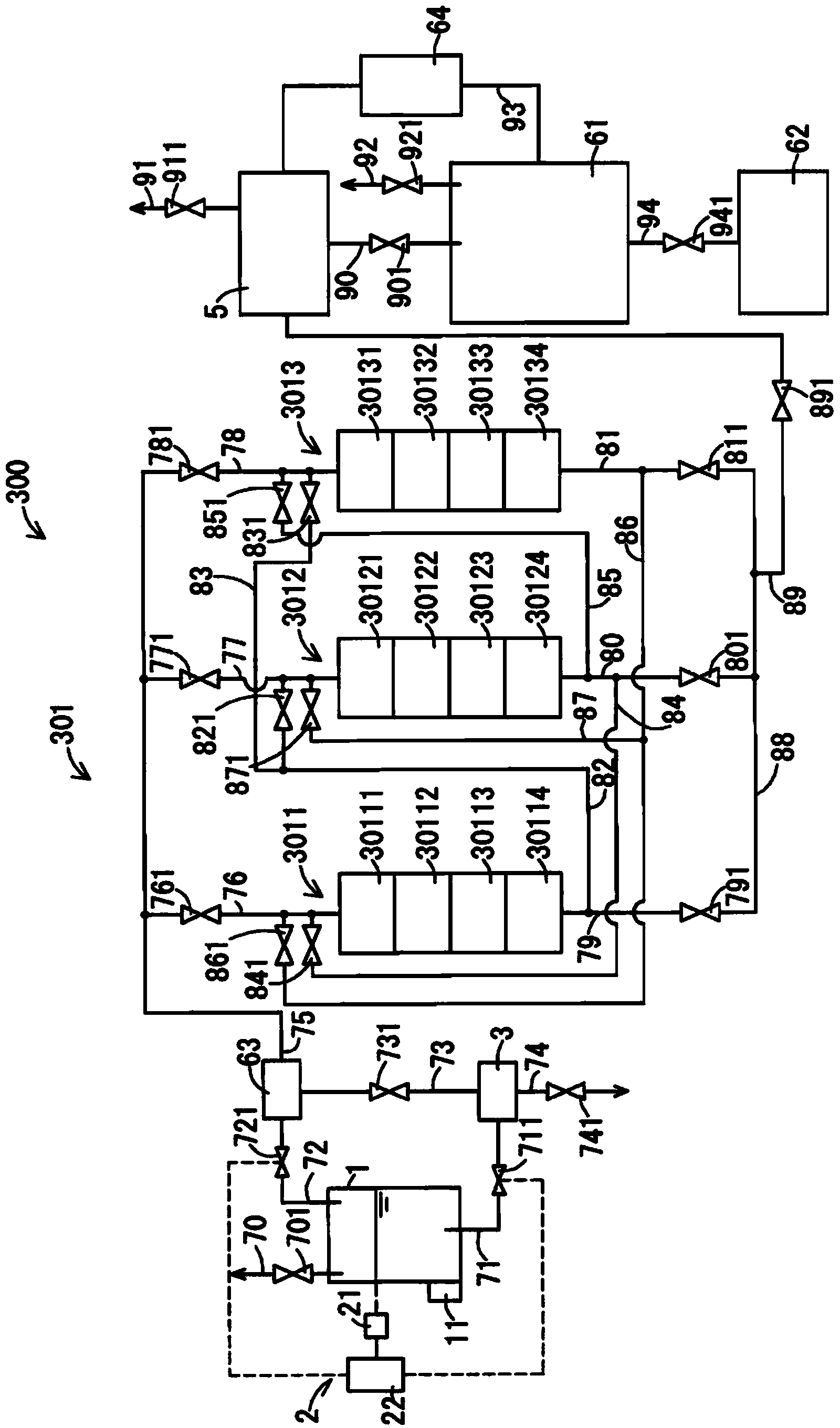

[0038] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0039] figure 1 It is a figure which shows the structure of the ammonia purification system 100 which concerns on 1st Embodiment of this invention. The ammonia purification system 100 of the present embodiment is a system for refining liquid crude ammonia containing impurities. The ammonia purification system 100 includes a raw material storage tank 1 as a storage part, a control unit 2 as a derivation control part, a vaporizer 3 as a gasification part, an adsorption unit 4 as an adsorption part, and a condenser 5 as a partial condensation part. , And recovery tank 61 and constitute.

[0040] The raw material storage tank 1 is a container for storing crude ammonia. In this embodiment, the crude ammonia stored in the raw material storage container 1 has a purity of 99% by weight or more, preferably a purity of 99.0 to 99.9% by weight.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com