Oil-gas well testing remote monitoring and management system

A remote monitoring and management system technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of large differences in specifications, models, configuration levels, equipment relocation, equipment without on-site data acquisition system, etc. Achieve the effects of reducing well patrol management costs, avoiding installation and deployment, and improving operation and management efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

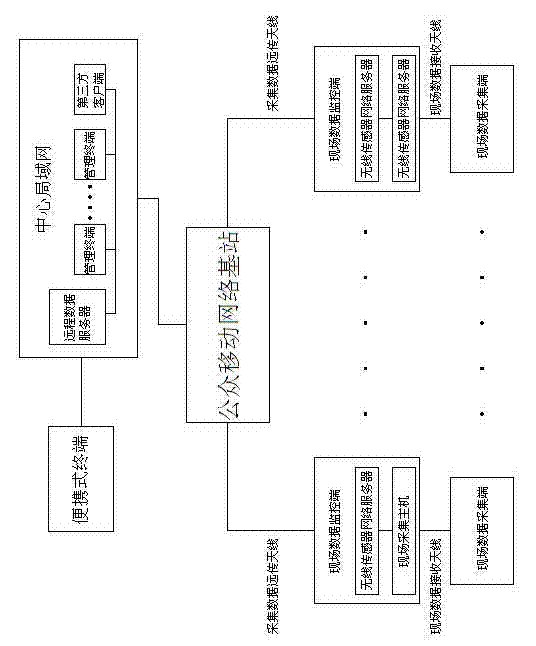

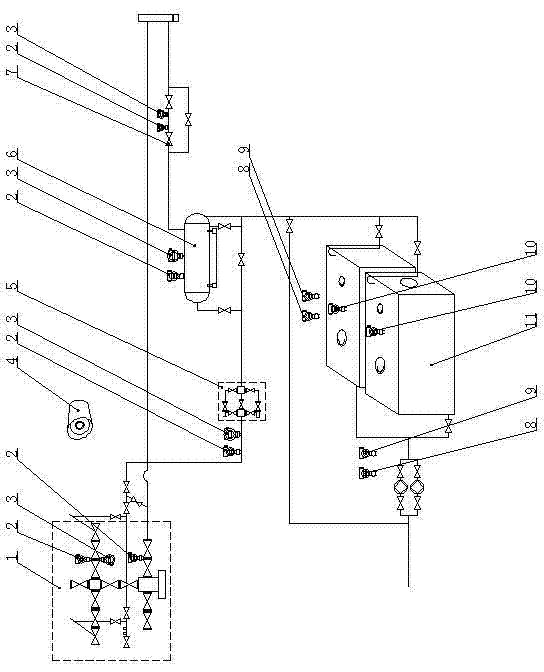

[0011] Example : Such as figure 1 , 2 As shown, the remote monitoring and management system for oil and gas well testing is composed of on-site data acquisition terminal, on-site data monitoring terminal, public mobile communication network, and central local area network. The on-site data acquisition terminal includes a wireless pressure transmitter 2 , a wireless temperature transmitter 3 , a wireless combustible gas monitoring sensor 8 , a wireless hydrogen sulfide monitoring sensor 9 and a wireless liquid level sensor 10 . The on-site data acquisition terminal realizes on-site data communication through the on-site data receiving antenna, wireless sensor network server and on-site acquisition host, monitors on-site production parameters in real time and completes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com