A high temperature electric head

A pan-tilt, electric technology, applied in machine/stand, optics, instruments, etc., can solve problems such as increased cost, inability to observe local details, monitoring dead ends, etc., to reduce work intensity, improve visualization, and reduce monitoring dead ends. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

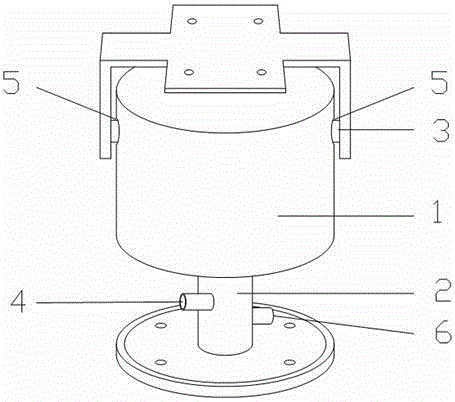

[0007] Below in conjunction with accompanying drawing, the present invention will be further described: with reference to figure 1 , a high-temperature electric pan-tilt includes a vertical rotation shaft 2 and a horizontal rotation shaft 3 assembled with the pan-tilt 1, the vertical rotation shaft 2 is a hollow shaft, and a cooling air inlet 4 is provided on the side wall at the bottom of the vertical rotation shaft 2, and the cloud There is a gap after the assembly holes on the two side walls of the table 1 are assembled with the two ends of the horizontal rotating shaft 3 , and the gap is the exhaust port 5 .

[0008] Design principle of the present invention: there are two inlets on the vertical rotating shaft 2 (hollow shaft) of the bottom of the cloud platform 1, one is the line inlet 6 of the internal motor control line of the platform, and the other is the cooling air inlet 4. The cooling air enters the inside of the gimbal from the inlet, exchanges with the hot air ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com