Expansion joints for cyclone separators

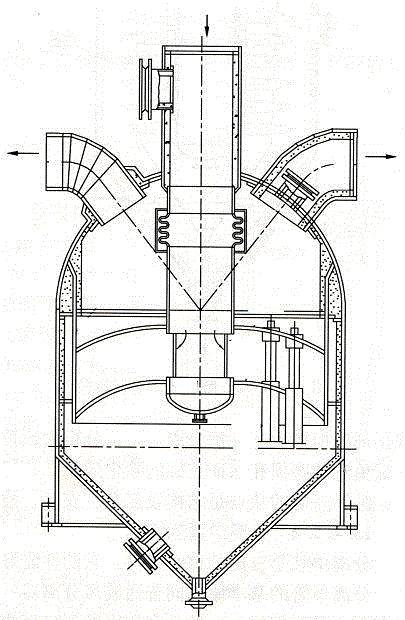

A cyclone separator and expansion joint technology, which is applied to expansion compensation devices for pipelines, pipes/pipe joints/pipes, mechanical equipment, etc. It can solve problems such as safe operation of the machine, so as to ensure long-term safe operation, improve the ability to compensate for multi-directional thermal expansion and displacement, and solve the effect of cracking or even falling off of connecting welds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in conjunction with accompanying drawing and specific embodiment:

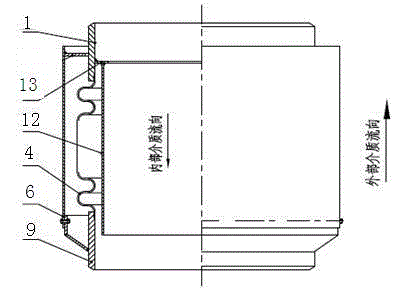

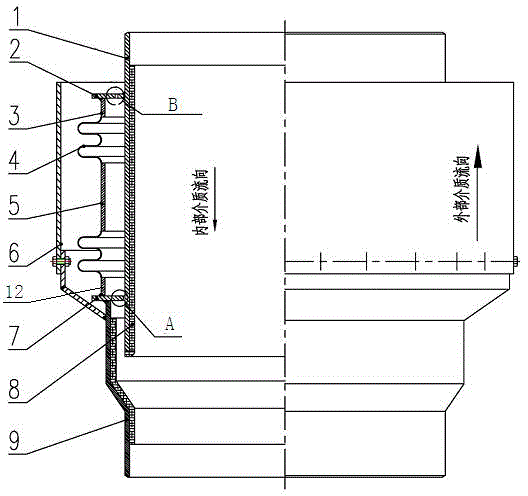

[0020] Such as image 3 As shown, an expansion joint for a cyclone separator device, the expansion joint includes an outlet end pipe 9, an inlet end pipe 1 and a corrugated pipe 4 that act as a flow guide; the inlet end pipe 1 that acts as a flow guide One end of the pipe is connected to the equipment through a connecting pipe, and the other end is located in the outlet pipe 9; the inner diameter of the inlet pipe 1 and the connecting pipe that act as a guide is the same as the inner diameter of the connected equipment, so that the flue gas can pass through smoothly The expansion joint avoids the impact of high-speed flue gas on the guide tube, which is beneficial to the protection of the bellows; the inner walls of the inlet end pipe 1 and the outlet end pipe 9 that play a role in diversion have wear-resistant linings 8; the bellows 4 is two groups, and the bellows 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com