Preparation and application of lipopeptide solution for low porosity and low permeability oil field displacement

An oil field and solution technology, which is applied in the preparation method of peptides, drilling compositions, peptides, etc., can solve problems such as formation scaling and blockage, and achieve the effect of enhancing the comprehensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

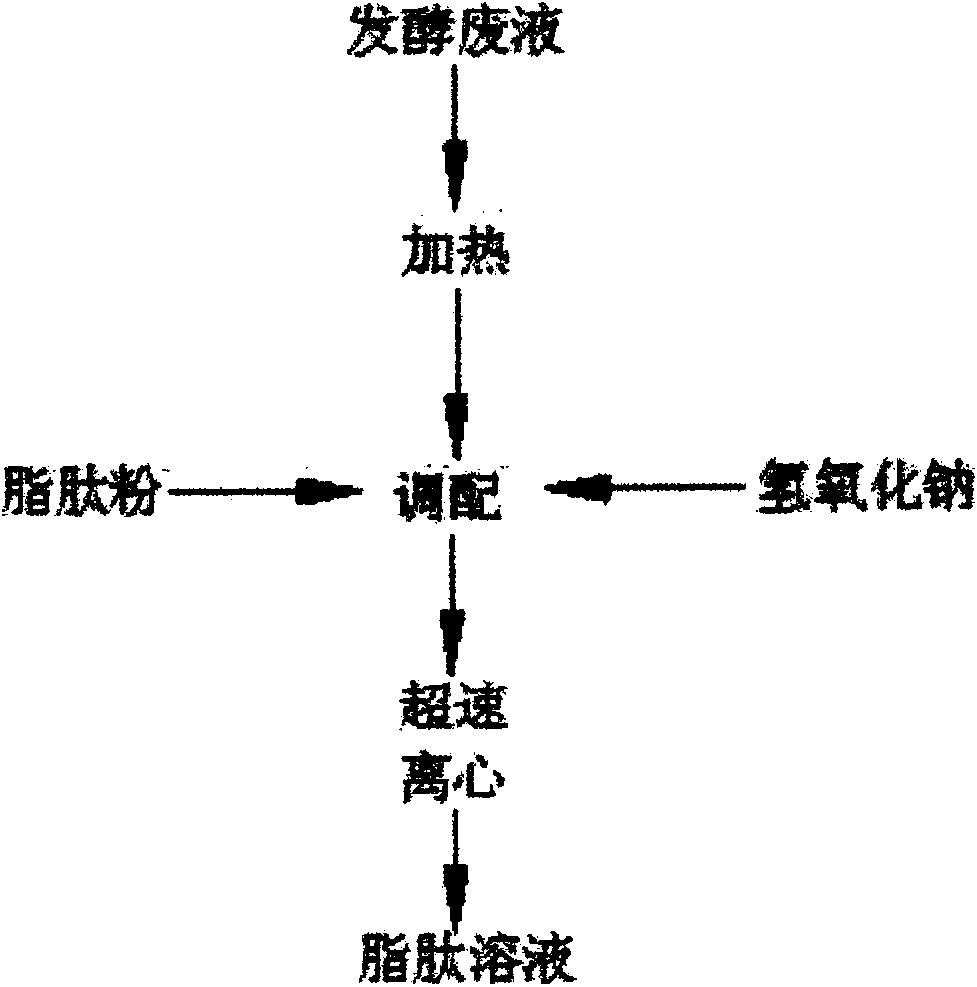

[0012] Heat the fermentation waste liquid with steam to 90°C, keep it warm for 20 minutes, detect bacteria-free bodies with spores by microscope smear, cool to 40°C and pour into the batching tank, add self-made lipopeptide powder in batches, adjust the pH to 9 with sodium hydroxide at all times, and stir until After complete dissolution, ultracentrifuge at 19000r / min and control the flow rate to obtain a clear lipopeptide solution. Most formations in Yanchang Oilfield have a permeability of about 1 mD and a porosity of about 10%, which belong to low-porosity and low-permeability formations. The lipopeptide solution was tested in a single well in an oil production plant in Yanchang Oilfield in July 2009. The oil increase rate is as high as 500%, and it stabilizes at about 100% in the later period, and the validity period is about 30 days. From December 2009 to December 2010, four water injection well groups were flooded with lipopeptide solution in an oil production plant in Y...

example 2

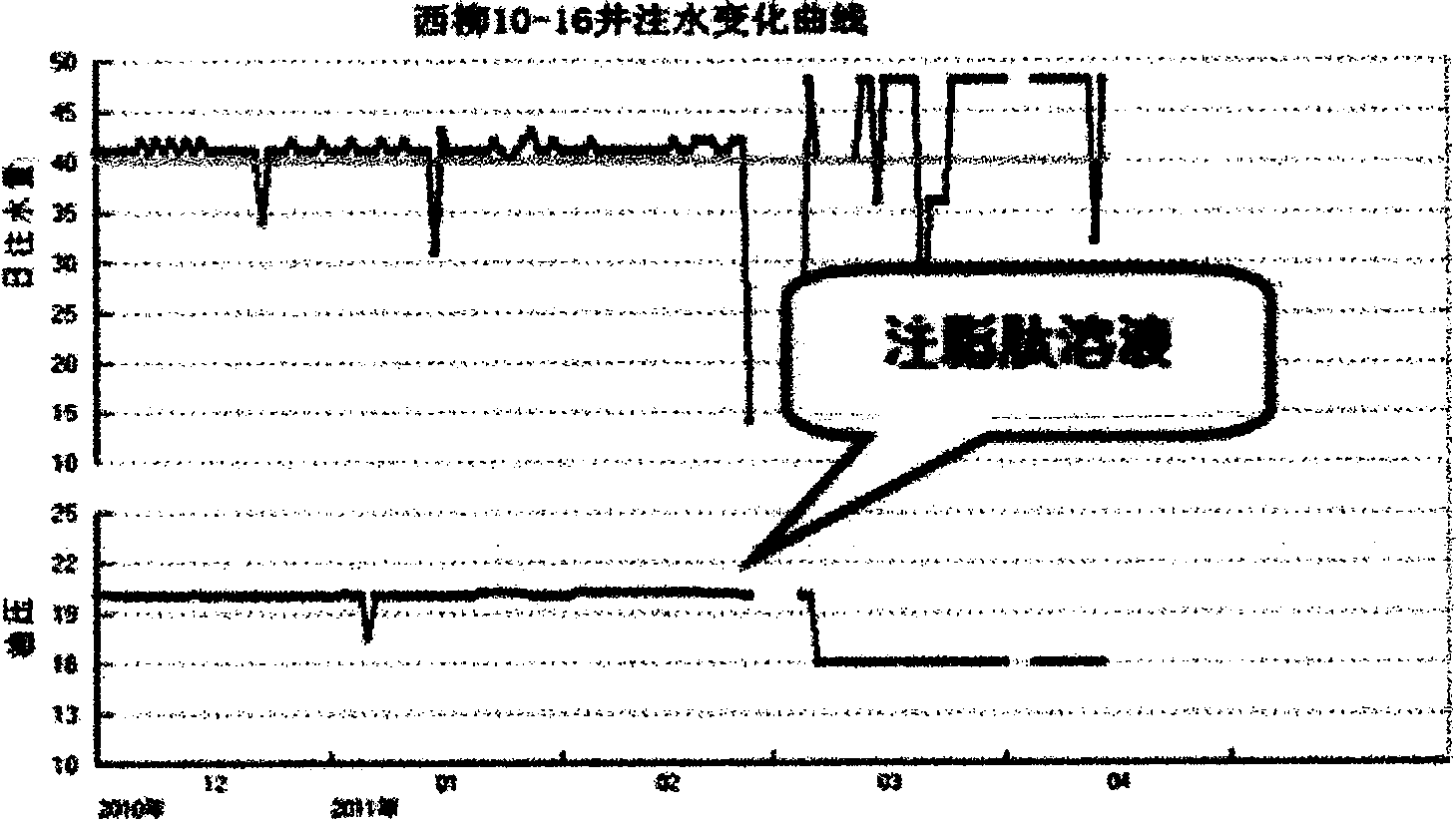

[0014] Heat the fermentation waste liquid with steam to 80°C, keep it warm for 30 minutes, detect bacteria-free bodies with spores on a microscope smear, cool to 30°C and pour into the batching tank, add self-made lipopeptide powder in batches, adjust the pH to 9 with sodium hydroxide at all times, and stir until After complete dissolution, ultracentrifuge at 18000r / min and control the flow rate to obtain a clear lipopeptide solution. The average porosity of the main well area of the West Liugong fault block in the No. 1 Oil Production Plant of Huabei Oilfield is 17.7%, and the permeability is 17.1×10 -3 um 2 , is a medium-porosity, low-permeability oil reservoir, gradually getting worse toward the west, with an average porosity of 15.1%, and a permeability of 7×10 -3 um 2 , is a medium-porosity, ultra-low permeability reservoir. The lipopeptide solution was applied in this work area. By October 2012, a total of 25 wells were constructed, providing 200 tons of lipopeptide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com