Light brick and preparation method thereof

A light-weight brick and biomass technology, which is applied to ceramic products, clay products, and other household appliances, can solve the problems of low utilization efficiency of biomass and other resources, can not be effectively used, and waste the calorific value of coal gangue, etc., to achieve heat preservation And sound insulation effect, light weight, improve the effect of roasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A lightweight brick, mainly prepared from the following raw materials in parts by weight:

[0044] 30 parts of domestic sludge with a water content of 80%,

[0045] 40 parts of coal gangue,

[0046] Kaolin tailings 20 parts,

[0047] Biomass - straw 5 parts,

[0048] 5 parts of sulfur-fixing, nitrogen-fixing and odor-removing agent,

[0049] The sulfur-fixing, nitrogen-fixing and odor-removing agent is composed of 95wt% calcium oxide and 5wt% potassium carbonate powder with particle size less than 0.1mm.

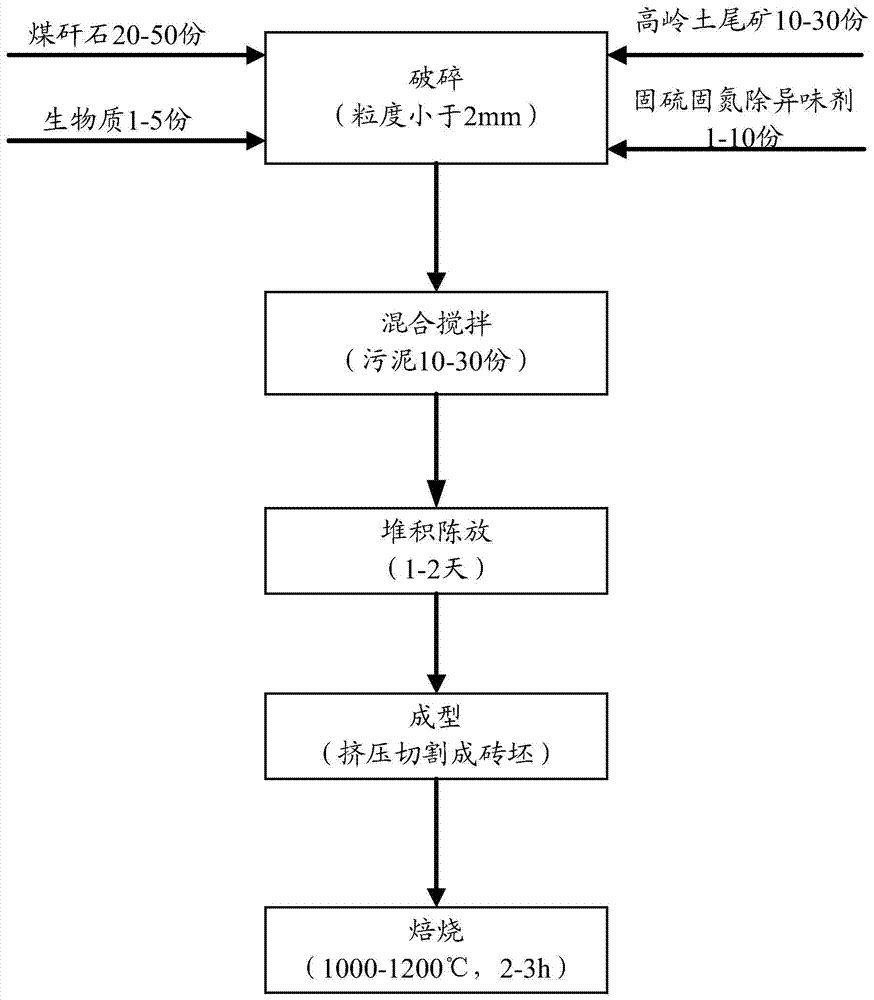

[0050] The preparation method of above-mentioned lightweight brick, comprises the following steps:

[0051] (1) Weigh the coal gangue, kaolin tailings, straw, sulfur-fixing and nitrogen-fixing agent according to the above parts by weight, and crush them until the particle size is less than 2mm;

[0052] (2) Weigh the sludge according to the above parts by weight, and add the pulverized coal gangue, kaolin tailings, biomass and sulfur and nitrogen fixation agent i...

Embodiment 2

[0057] Lightweight bricks are mainly prepared from the following raw materials in parts by weight:

[0058] 20 parts of domestic sludge with a water content of 60%,

[0059] 50 parts of coal gangue,

[0060] 30 parts of kaolin tailings,

[0061] Biomass - straw 5 parts,

[0062] 10 parts of sulfur-fixing, nitrogen-fixing and odor-removing agent,

[0063] The sulfur-fixing, nitrogen-fixing and odor-removing agent is composed of 90wt% calcium oxide and 10wt% potassium carbonate powder with particle size less than 0.1mm.

[0064] The preparation method of the above-mentioned lightweight brick is basically the same as that of Example 1, except that the aging time in step (3) is 48 hours, and the firing temperature in step (5) is 1000° C. for 3 hours.

Embodiment 3

[0066]Lightweight bricks are mainly prepared from the following raw materials in parts by weight:

[0067] 10 parts of domestic sludge with a water content of 80%,

[0068] 20 parts of coal gangue,

[0069] Kaolin tailings 10 parts,

[0070] Biomass - 1 part of straw,

[0071] 1 part of sulfur-fixing, nitrogen-fixing and odor-removing agent,

[0072] The sulfur-fixing, nitrogen-fixing and odor-removing agent is composed of 99wt% calcium oxide and 1wt% potassium carbonate powder with particle size less than 0.1mm.

[0073] The preparation method of the above-mentioned lightweight brick is basically the same as that of Example 1, except that the aging time in step (3) is 32 hours, and the firing temperature in step (5) is 1200° C. for 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com