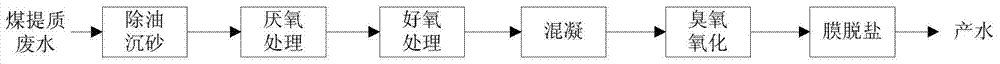

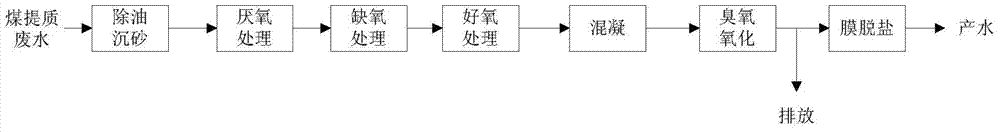

Coal upgrading wastewater treatment process

A treatment process and wastewater treatment technology, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., which can solve the problems of loss of thermal energy utilization rate, increase of chemical consumption, and short process flow. , to achieve the effect of saving operating costs, reducing the dosage of chemicals, and strong process applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A coal upgrading wastewater treatment process, comprising the steps of:

[0056] (1) Degreasing and grit treatment

[0057] After the waste water has been naturally clarified for 5 hours, the supernatant liquid is mixed with degreasing and sand-setting agents, and then enters the mud-water separation area, the supernatant liquid enters the biochemical treatment, and the sludge enters the sludge treatment system for concentration treatment through a belt filter press; The above-mentioned degreasing agent is polyferric sulfate and polyacrylamide, and the dosage of the two is 1500ml / L and 10mg / L respectively; radial flow sedimentation tank can be used for mud-water separation;

[0058] (2) Biochemical treatment

[0059] The supernatant after the degreasing and sanding treatment enters the biochemical treatment system, and the biochemical reaction of microorganisms is used to remove most of the pollutants in the wastewater; the biochemical treatment system includes an anae...

Embodiment 2

[0065] A coal upgrading wastewater treatment process, comprising the steps of:

[0066] (1) Degreasing and grit treatment

[0067] After the wastewater has been naturally clarified for 2 hours, the supernatant liquid is mixed with degreasing and sand-setting agents, and then enters the mud-water separation area, the supernatant liquid enters biochemical treatment, and the sludge enters the sludge treatment system for concentration treatment through a decanter centrifuge; The degreasing and sanding agents are polyferric sulfate and polyacrylamide, the dosage of which is 500ml / L and 30mg / L respectively; mud-water separation can be done by inclined plate settling tank;

[0068] (2) Biochemical treatment

[0069] The supernatant after the degreasing and sanding treatment enters the biochemical treatment system, and the biochemical reaction of microorganisms is used to remove most of the pollutants in the wastewater; the biochemical treatment system includes an anaerobic pool and ...

Embodiment 3

[0075] A coal upgrading wastewater treatment process, comprising the steps of:

[0076] (1) Degreasing and grit treatment

[0077] After the waste water has been naturally clarified for 3 hours, the supernatant liquid is mixed with degreasing and sand-setting agents, and then enters the mud-water separation area, the supernatant liquid enters the biochemical treatment, and the sludge enters the sludge treatment system for concentration treatment through a plate and frame filter press; The above-mentioned degreasing agent is polyferric sulfate and polyacrylamide, and the dosage of the two is 1000ml / L and 15mg / L respectively; radial flow sedimentation tank can be used for mud-water separation;

[0078] (2) Biochemical treatment

[0079] Enter the supernatant after degreasing and grit treatment into the biochemical treatment system, and use the biochemical reaction of microorganisms to remove most of the pollutants in the wastewater; the biochemical treatment system includes ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com