Seven-axis linkage numerical control abrasive belt grinding and polishing machine tool

A technology of abrasive belt grinding and linkage, which is applied in the direction of abrasive belt grinders, grinding machine parts, grinding machines, etc., can solve the problems of inability to stably remove uneven margins on curved surfaces, overcutting and undercutting, and achieve high grinding and polishing efficiency , Eliminate the interference of the gravitational component of the grinding head, and facilitate the replacement of the abrasive belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below with reference to the accompanying drawings and examples, and the embodiments of the present invention include but not limited to the following examples.

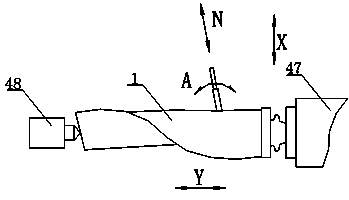

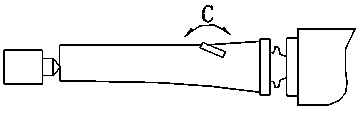

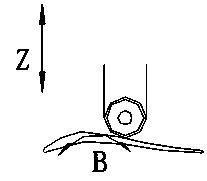

[0033] like figure 1 , figure 2 and image 3 and Figure 4 , Figure 5 , Figure 8 As shown, the blade part 1 is installed between the rotary fixture 47 and the top 48, the rotary fixture 47 is installed on the B-axis rotary drive mechanism 23, the top is installed on the X-direction lifting slide 38, and the B-axis servo motor 37 drives the B-axis rotary mechanism The internal worm gear drives the rotary fixture to realize 360° rotary motion. The X-direction lifting slide 38 is installed on the two X-axis guide rails 31 vertically arranged on the column 22 through a slider. Specifically, the X-axis servo motor is connected with the X-direction ball screw 50, and the X-direction ball screw is installed on the X-axis. On the screw seat 51, and connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com