Slow cooling device and method for steel plates

A slow cooling device and steel plate technology, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of difficult timing of lifting out steel plates, expensive construction of insulation pits, increased maintenance and repair costs, etc., to achieve Eliminate white spot defects, avoid maintenance and repair costs, and achieve the effect of timely connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

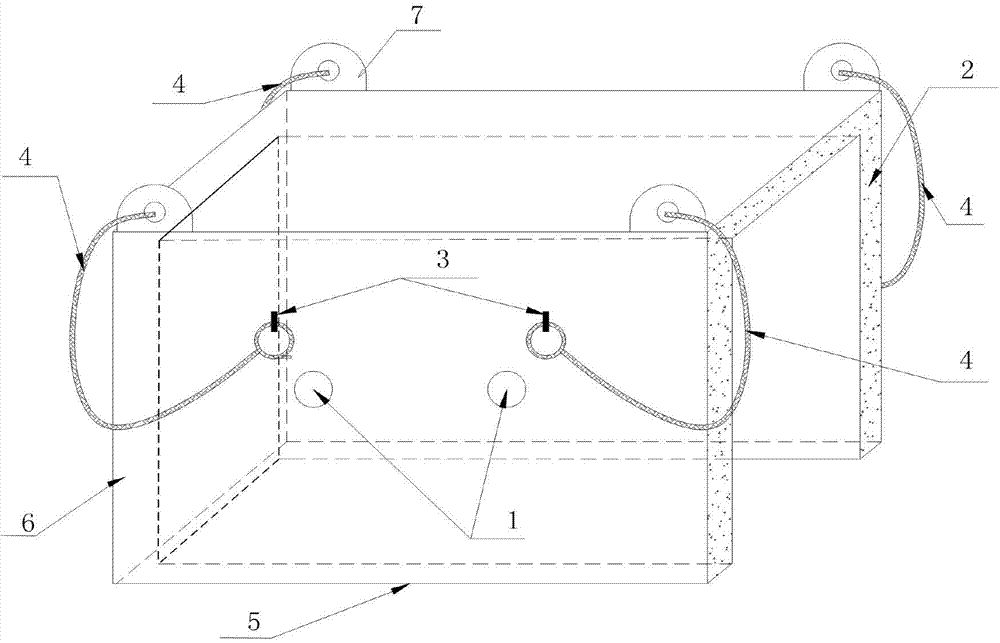

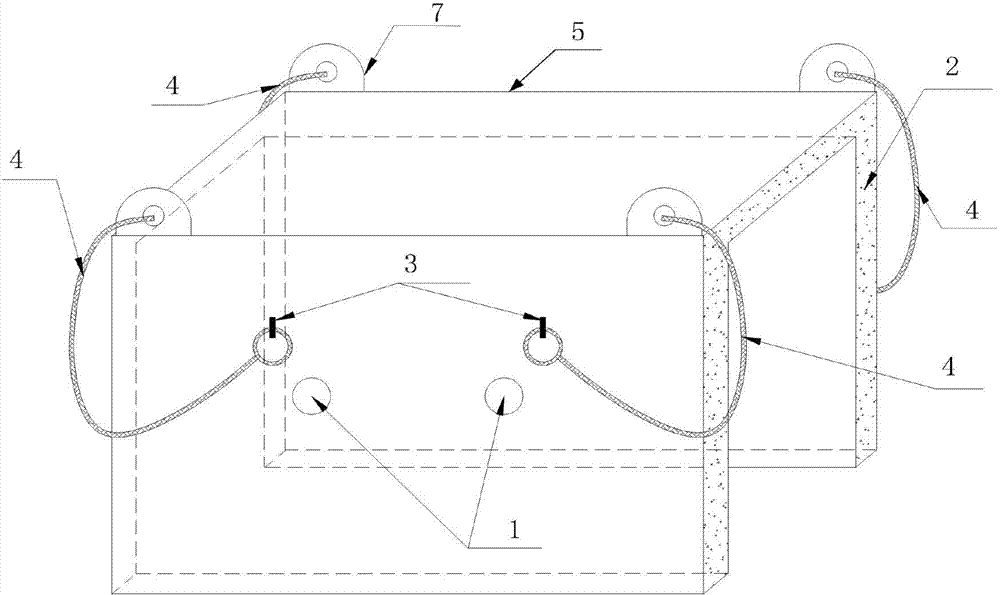

[0042] The production of wide and thick plate steel for wind power that requires Class I flaw detection is Q345BZ15. After the steel plate is rolled, it will be stacked immediately in a red hot state, and the end box and the middle box will be used to cover the stack. After 20 hours The temperature of the steel plate is slowly lowered to below the ideal temperature of 150°C. The results of metallographic experiments after sampling the steel plate show that there are no white spot defects in the internal structure of the steel plate, and at the same time, the thermal stress and structural stress caused by the recooling process of the hot steel plate are effectively avoided. The cracks meet the requirements of Class I flaw detection.

Embodiment example 2

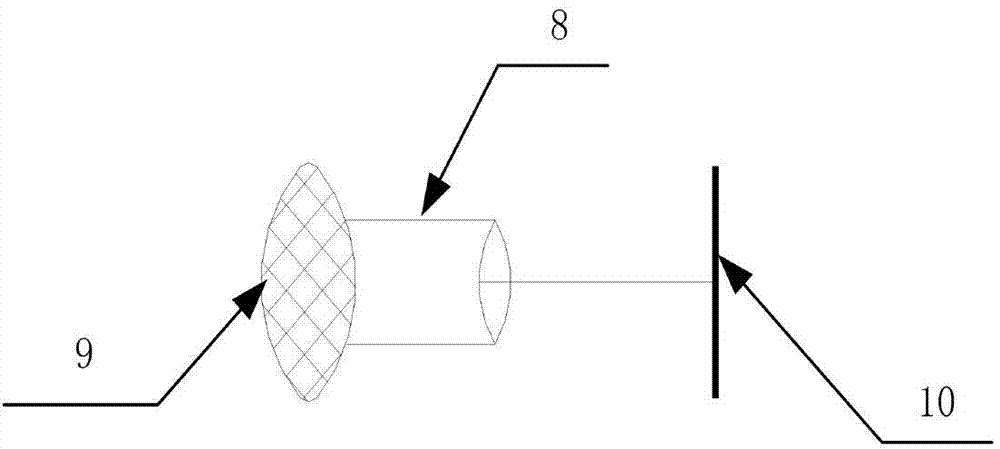

[0044]Wide and thick plate production line, the end box and the middle box are used to cover the stack during production, the actual temperature of the steel plate is detected in real time through the temperature measuring hole during the slow cooling process of the steel plate, and the reasonable timing of opening the slow cooling device to lift out the steel plate is accurately grasped ( The ideal temperature is below 150°C), which ensures the slow cooling effect of the steel plate. The pass rate of flaw detection of the steel plate has risen from 91% per quarter to 99.5%, reaching the domestic first-class level, thereby achieving the purpose of improving the product yield, resulting in great Considerable economic benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com