Wire-tubular-type low temperature plasma unit reactor and assembly system thereof

A low-temperature plasma and combined system technology, applied in the field of plasma unit reactors and their combined systems, can solve the problems of complex structure, poor sealing, poor safety, etc., and achieve the effects of high anti-oxidation performance, elimination of peculiar smell, and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Various embodiments of the present invention will be described in detail below with reference to the accompanying drawings, in which the same structures or functions are marked with the same numerals. It should be pointed out that the purpose of the drawings is only to facilitate the description of the specific embodiments of the present invention, and is not a redundant description or limitation to the scope of the present invention. In addition, the drawings are not necessarily drawn to scale.

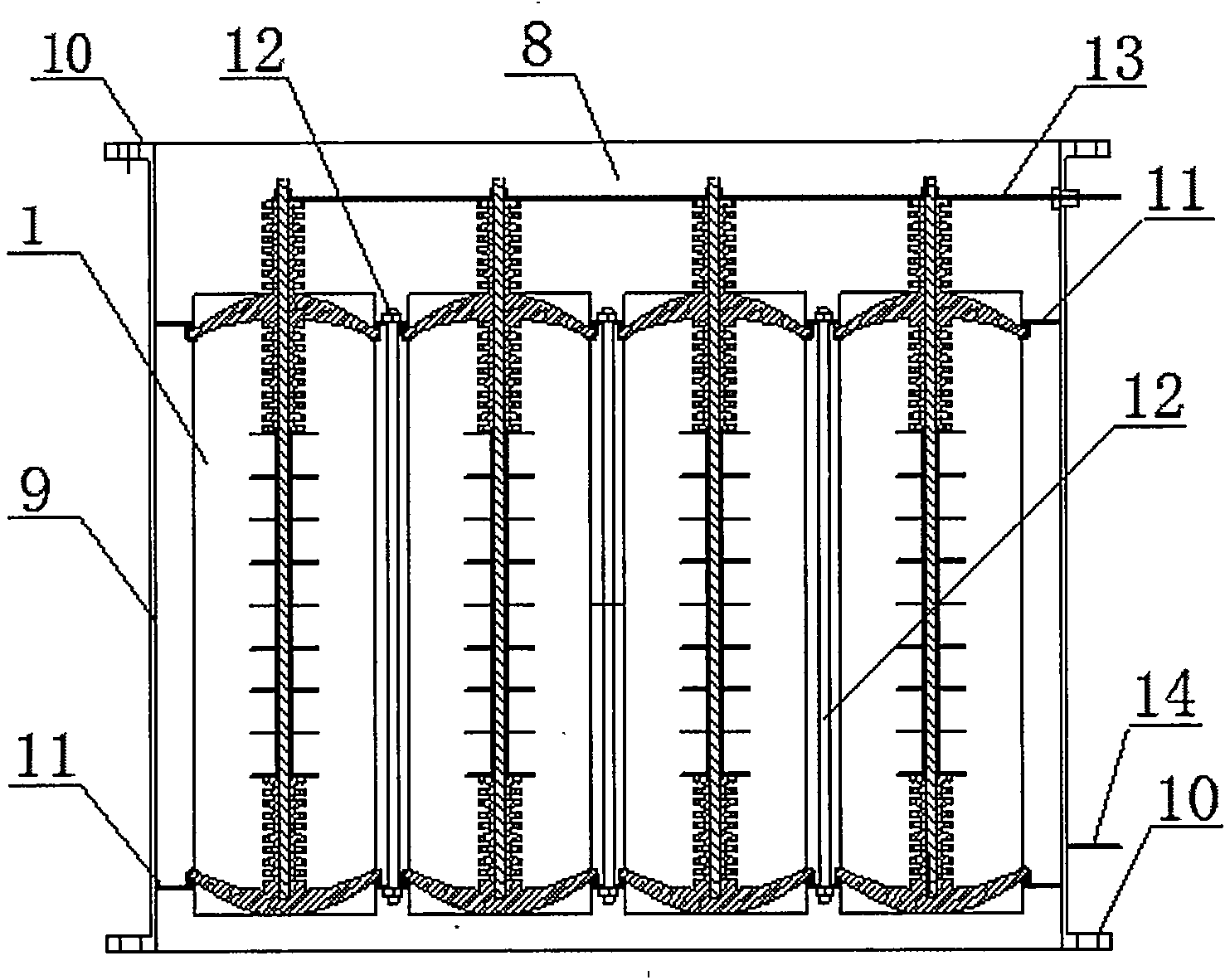

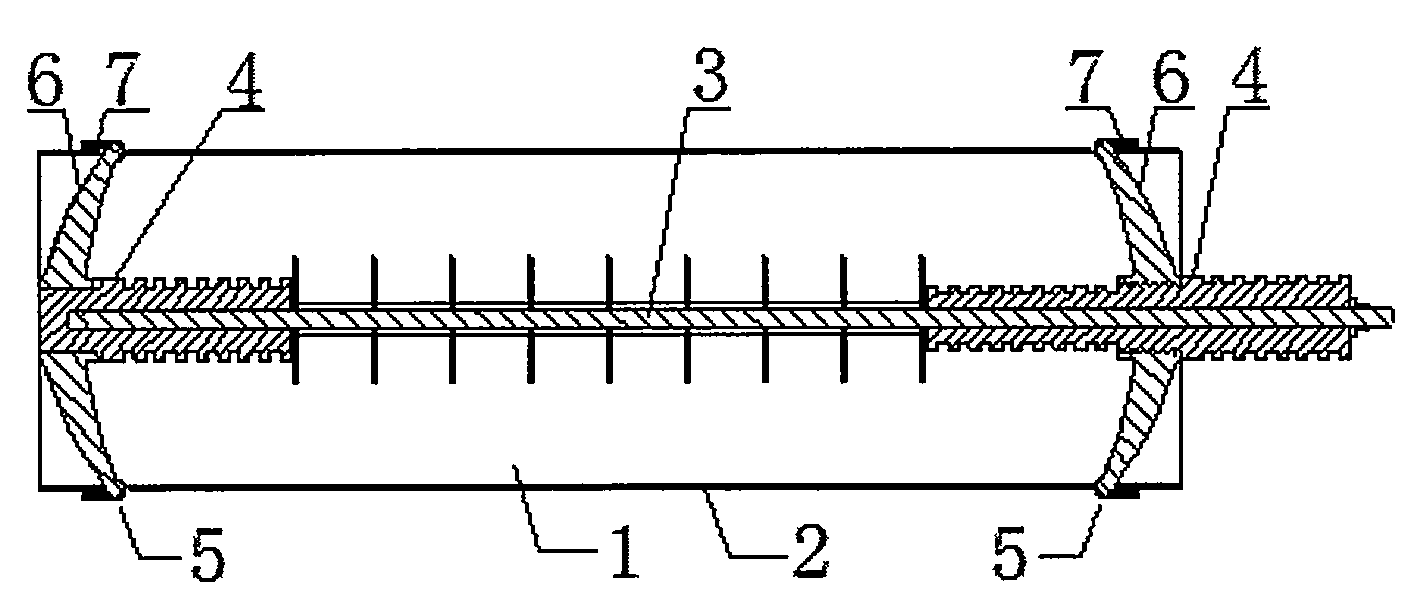

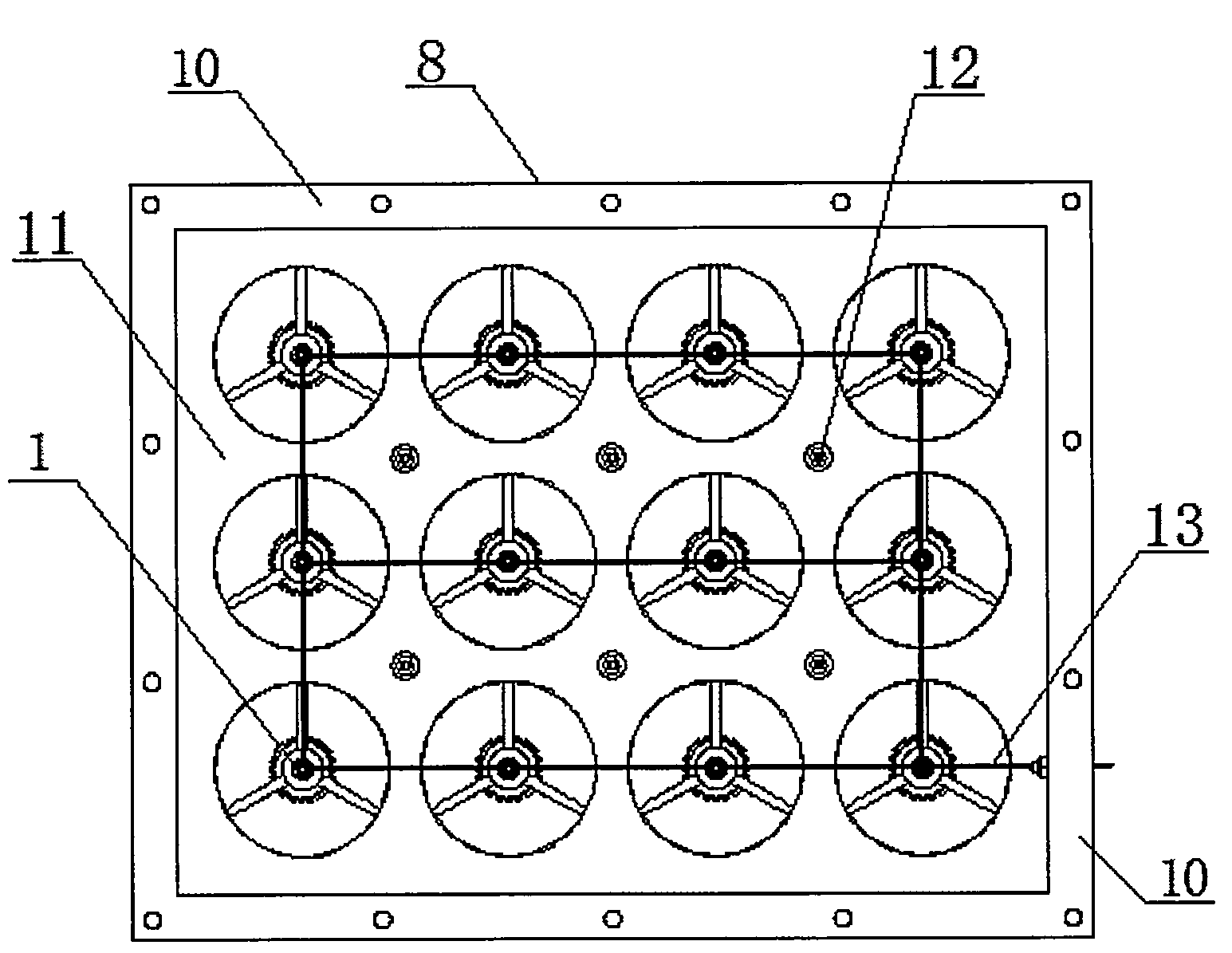

[0072] The invention provides a line-pipe type low-temperature plasma unit reactor and its combination system, the line-pipe type low-temperature plasma unit reactor, such as figure 1 , 2 As shown, it is composed of the positive electrode (1) of the reactor, the outer electrode (2) of the circular tube and the sealing ring (7).

[0073] Wherein, the positive electrode (1) of the reactor is composed of different types of central electrodes (3) and insulating components (4), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com