Multivariate plant nutrition oil and preparation method thereof

A technology of nutritional oil and vegetable oil, which is applied in the field of oil processing and can solve the problems of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

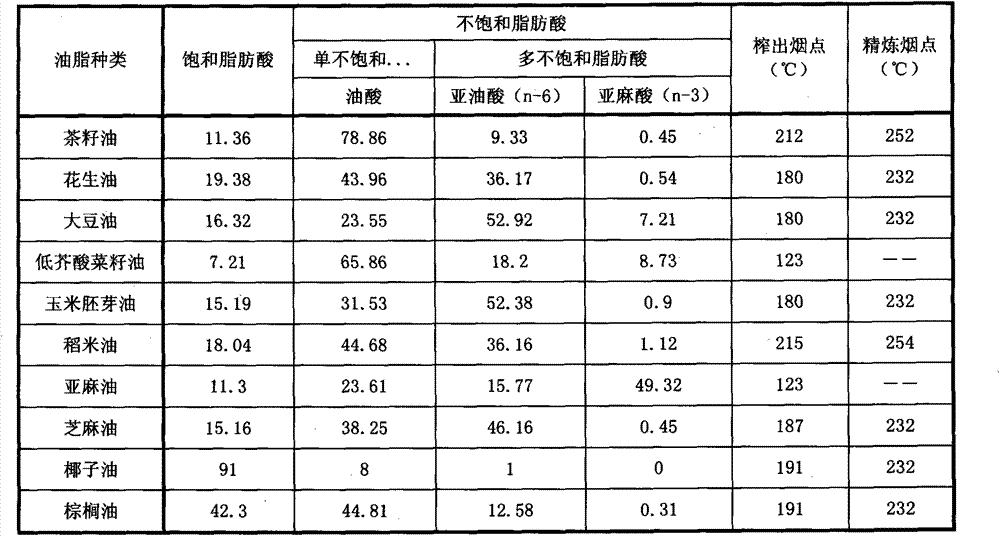

Method used

Image

Examples

Embodiment 1

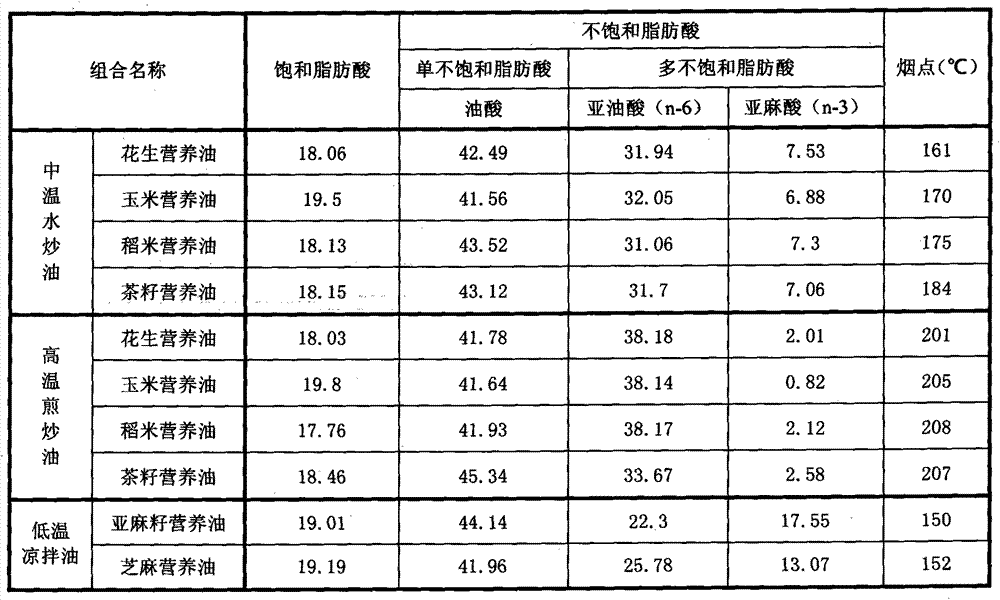

[0079] A water-fried "peanut nutrient oil" prepared in 1000kg. Take 350kg of peanut oil, 250kg of canola oil, 250kg of corn germ oil, 100kg of linseed oil and 50kg of coconut oil into the preparation tank, add in the order of the largest amount and stir, keep the temperature at 50°C, and control the speed at 20r / min, stirring time 10min, then quickly pump into the refrigeration device, cool to 5°C, add phytonutrients, antioxidants and emulsifiers, stir for 5min, let stand for 12h, fine filter, sampling test, fine-tuning, packaging, water Fried peanut nutritious oil.

[0080] The prepared fatty acid content of the water-fried peanut nutrient oil: the content of saturated fatty acid is 18.06%, the content of monounsaturated fatty acid is 42.49%, the content of n-6 polyunsaturated fatty acid is 31.94%, the content of n-3 polyunsaturated fatty acid is 7.53%, Other functional nutrients and trace elements are omitted here, and the smoke point is 161°C;

Embodiment 2

[0082] A water-fried "corn nutrient oil" is prepared in 1000kg. Take 320kg of corn germ oil, 270kg of canola oil, 250kg of rice oil, 80kg of linseed oil and 80kg of coconut oil and put them into the preparation tank, add and stir in the order of adding the largest amount first, keep the temperature at 60°C, and control the speed of 30r / min, stirring time 20min, then quickly pumped into the refrigeration device, cooled to 15°C, added phytonutrients, antioxidants and emulsifiers, stirred for 10min, stood for 24h, finely filtered, sampled and tested, fine-tuned, packaged, and obtained Water fried corn nutrition oil.

[0083] Each fatty acid content of the water-fried corn nutrient oil: saturated fatty acid content is 19.5%, monounsaturated fatty acid content is 41.56%, n-6 polyunsaturated fatty acid content is 32.05%, n-3 polyunsaturated fatty acid content is 6.88%, Other functional nutrients and trace elements are omitted here, and the smoke point is 170°C;

Embodiment 3

[0085] A water-fried "rice nutrient oil" is prepared in 1000kg. Take 300kg of rice oil, 250kg of corn germ oil, 200kg of canola oil, 100kg of linseed oil and 150kg of palm oil and add them into the preparation tank, add them in the order of the first large amount and stir, keep the temperature at 55°C, and control the speed of 20r / min, stirring time 20min, then quickly pumped into the refrigeration device, cooled to 10°C, added phytonutrients, antioxidants and emulsifiers, stirred for 10min, stood for 16h, finely filtered, sampled and tested, fine-tuned, packaged, and obtained Water-fried rice nutritious oil.

[0086] Each fatty acid content of the fried rice nutrient oil: saturated fatty acid content is 18.13%, monounsaturated fatty acid content is 43.52%, n-6 polyunsaturated fatty acid content is 31.06%, n-3 polyunsaturated fatty acid content is 7.3%, Other functional nutrients and trace elements are omitted here, and the smoke point is 175°C;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com