Electric vehicle motor controller and controller assembly modularization unit structure mode

A technology for motor controllers and electric vehicles, applied in AC motor control, electrical components, control systems, etc., can solve the problems of time-consuming and labor-intensive manufacturing work, no heat dissipation design for heat, electromagnetic field radiation interference, etc., and achieve simplified structure and assembly process , reduce the number of internal components, reduce the effect of internal temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0117] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

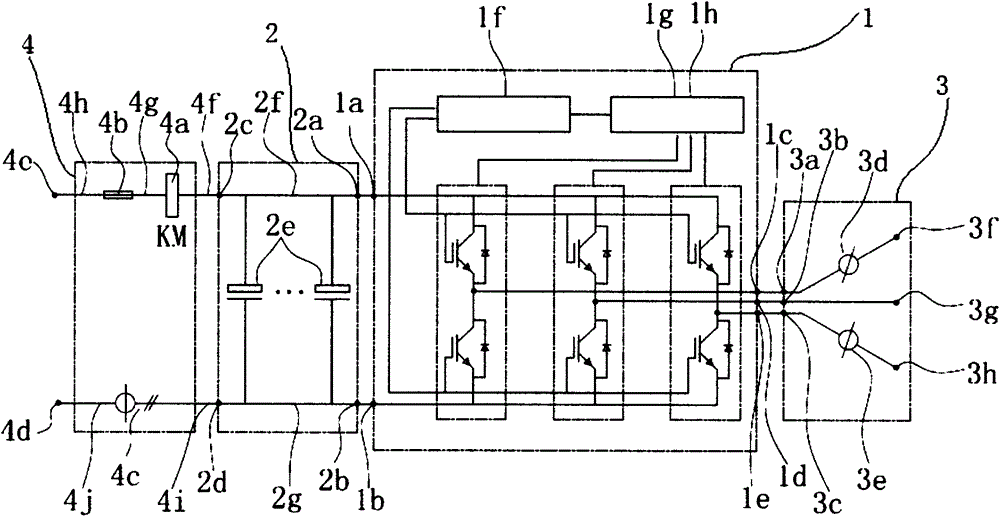

[0118] figure 1 It is a circuit structure diagram showing the "electric vehicle motor controller and controller assembly modular unit structure" of the present invention. The AC motor drive control of vehicles such as pure electric passenger cars is equipped on such vehicles.

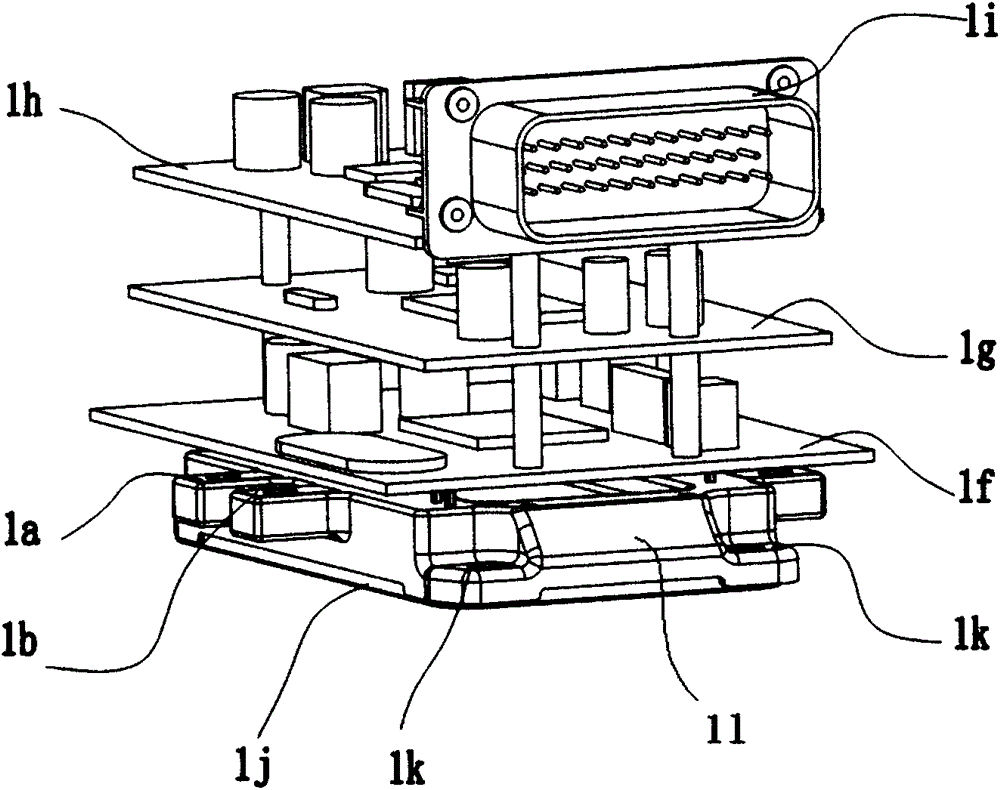

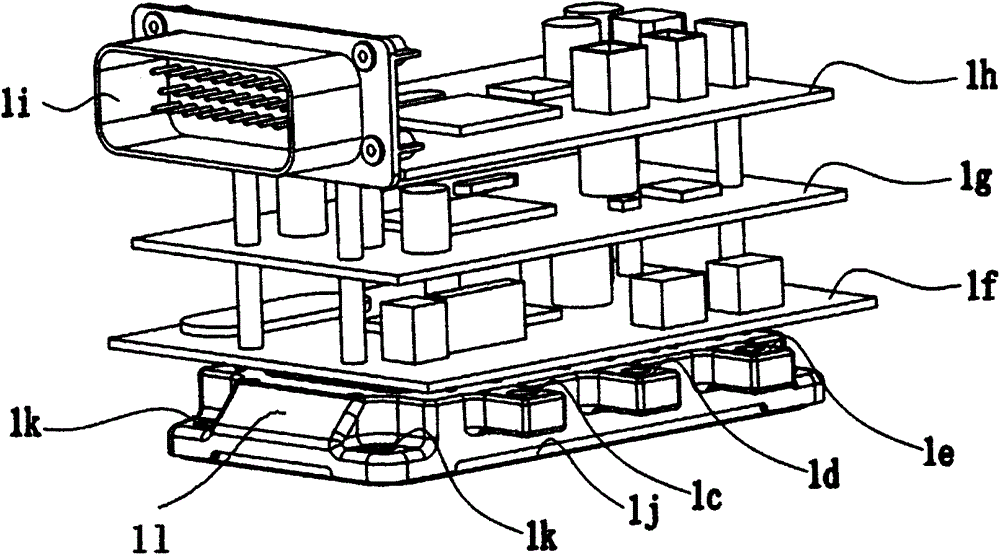

[0119] 1 in this figure is a power semiconductor module and a drive control board unit, which has three parts: a power semiconductor circuit 1l, a semiconductor drive unit 1f, and a motor control ECU unit 1g, 1h; it also includes semiconductor input busbar terminals 1a, 1b, and output terminals 1c, 1d, 1e; where the power semiconductor circuit is a three-phase switch conversion circuit module 1l, this unit is the core part of the motor controller and controller assembly.

[0120] figure 1 The middle 2 is a capacitor integrated module. In the present invention, the capacitor int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com