Thin-substrate phase amplitude correction oscillator planar horn antenna

A technology of horn antenna and amplitude correction, which is applied in the direction of waveguide horn, radiating element structure, circuit, etc., can solve the problems of low horn antenna gain, narrow working frequency band, large patch size, etc., and achieve the correction of phase and amplitude inconsistency, feed The effect of small power loss and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

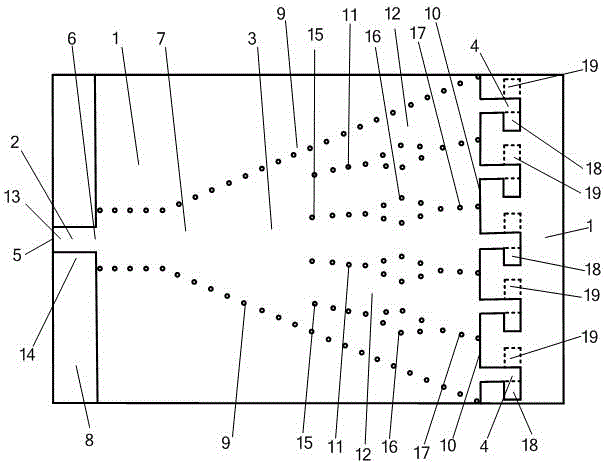

[0024]The embodiment adopted in the present invention is: the thin substrate phase amplitude correction vibrator planar horn antenna includes a microstrip feeder 2 arranged on a dielectric substrate 1, a substrate integrated horn antenna 3 and a plurality of vibrators 4; the microstrip feeder 2 The first port 5 of the antenna is the input and output port of the antenna, and the second port 6 of the microstrip feeder 2 is connected to the substrate integrated horn antenna 3; the substrate integrated horn antenna 3 is formed by the first metal plane 7 located on one side of the dielectric substrate 1 , the second metal plane 8 located on the other side of the dielectric substrate 1 and two rows of metallized via-hole horn sidewalls 9 passing through the dielectric substrate 1 to connect the first metal plane 7 and the second metal plane 8, the substrate integrates the horn antenna 3 The width between the horn side walls 9 of the two rows of metallized via holes gradually increase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com