Preparation method for commercial vanadium battery electrolyte

An electrolyte and vanadium battery technology, applied in the field of vanadium battery electrolyte preparation, can solve the problems of increasing the preparation cost, cumbersome reaction process, increasing the reaction process, etc., achieving good economic and social benefits, shortening the process process, and reducing impurities The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

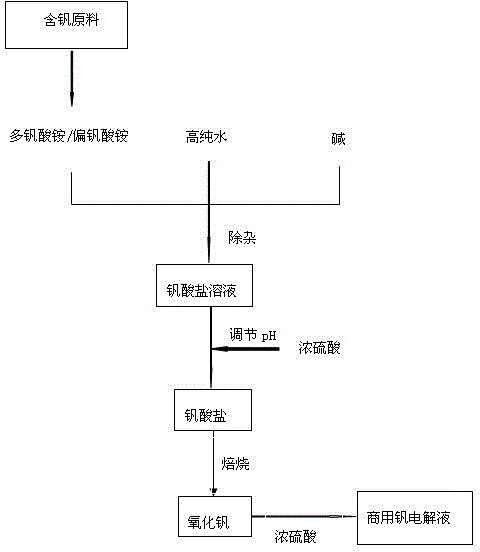

[0031] Example 1: figure 1 As shown, the specific process of the preparation method of the vanadium battery electrolyte is as follows.

[0032] Ammonium polyvanadate is used as raw material, sodium hydroxide is added to dissolve it, the filtrate is adjusted to pH 9, and aluminum sulfate is added to remove impurities. After removing impurities, adjust the pH value of the filtrate to 1.5, and heat to precipitate ammonium polyvanadate. Then redissolve the ammonium polyvanadate with ammonia water, adjust the pH value to 2.0 to sink the ammonium polyvanadate, filter and dry, then burn vanadium trioxide at 800°C under the condition of feeding ammonia gas, and then make the divanadium trioxide Vanadium and concentrated sulfuric acid are mixed and stirred, and high-purity water is added to dissolve and then filtered to obtain a vanadium electrolyte. The impurity content of the obtained vanadium electrolyte is Al<17ppm, Na<15ppm, Fe<15ppm, Ca<15ppm, K<10ppm, Cr<5ppm, and the contents...

Embodiment 2

[0033] Embodiment 2: The specific process of the preparation method of the vanadium battery electrolyte is as follows.

[0034] Using ammonium polyvanadate as raw material, add ammonia water to dissolve it under heating, adjust the pH value of the filtrate to 7.5, and add sodium metaaluminate to remove impurities. After removing impurities, adjust the pH value of the filtrate to 1.9, and heat to precipitate ammonium polyvanadate. Then ammonium polyvanadate was redissolved with ammonia water, and the pH value was adjusted to 2.3 to deposit ammonium polyvanadate. After filtration and drying, vanadium trioxide was fired at 800°C under the condition of feeding ammonia gas, and then the divanadium trioxide was Vanadium and concentrated sulfuric acid are mixed and stirred, and high-purity water is added to dissolve and then filtered to obtain a vanadium electrolyte. The impurity content of the obtained vanadium electrolyte is Al<17ppm, Na<15ppm, Fe<15ppm, Ca<15ppm, K<10ppm, Cr<5ppm...

Embodiment 3

[0035] Embodiment 3: The specific process of the preparation method of the vanadium battery electrolyte is as follows.

[0036] Vanadium pentoxide is used as raw material, potassium hydroxide is added to dissolve it, the filtrate is adjusted to a pH value of 8-9, and aluminum chloride is added to remove impurities. After removing impurities, adjust the pH value of the filtrate to 10, and heat to precipitate ammonium polyvanadate. Then ammonium polyvanadate was redissolved with potassium hydroxide, and the pH value was adjusted to 2.3 to deposit ammonium polyvanadate. After filtration and drying, vanadium trioxide was fired at 800°C under the condition of feeding ammonia gas, and then the three Mix vanadium oxide with concentrated sulfuric acid, add high-purity water to dissolve, and filter to obtain vanadium electrolyte. The impurity content of the obtained vanadium electrolyte is Al<17ppm, Na<16ppm, Fe<15ppm, Ca<25ppm, K<10ppm, Cr<5ppm, and the contents of other impurity ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com