Method for preparing iron disulfide/carbon composite positive electrode material for disposable lithium battery and method for assembling button battery by using positive electrode material

A technology of iron disulfide, positive electrode material, applied in battery electrodes, circuits, electrical components, etc., to achieve the effect of reducing open circuit voltage, improving wettability and electronic conductivity, and increasing effective specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

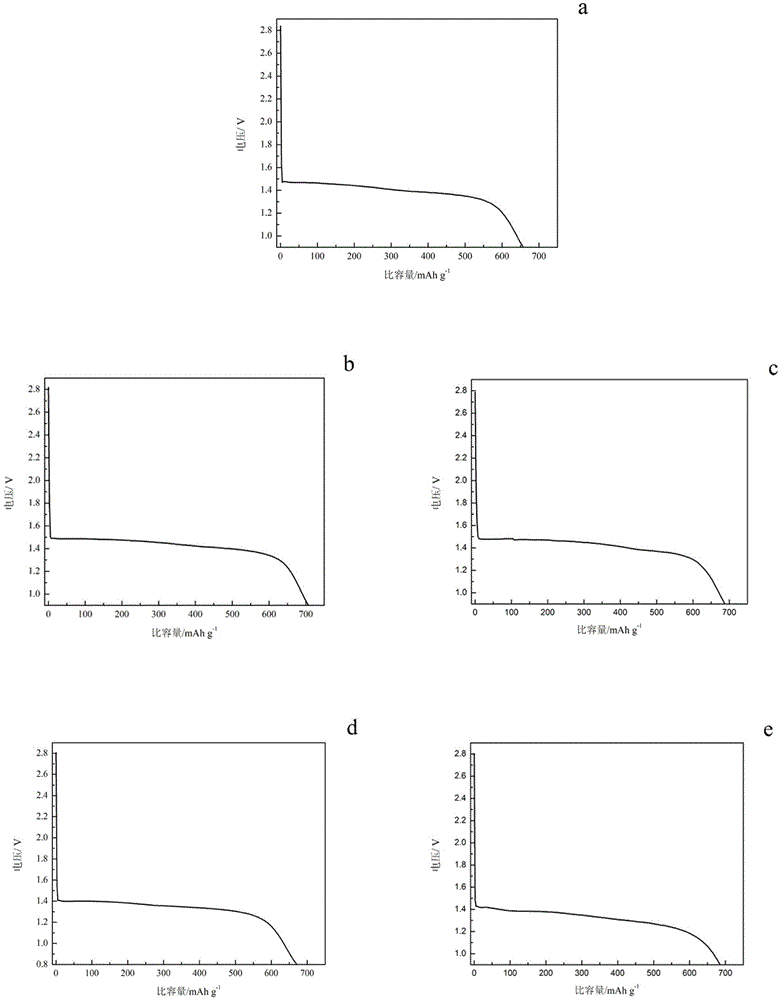

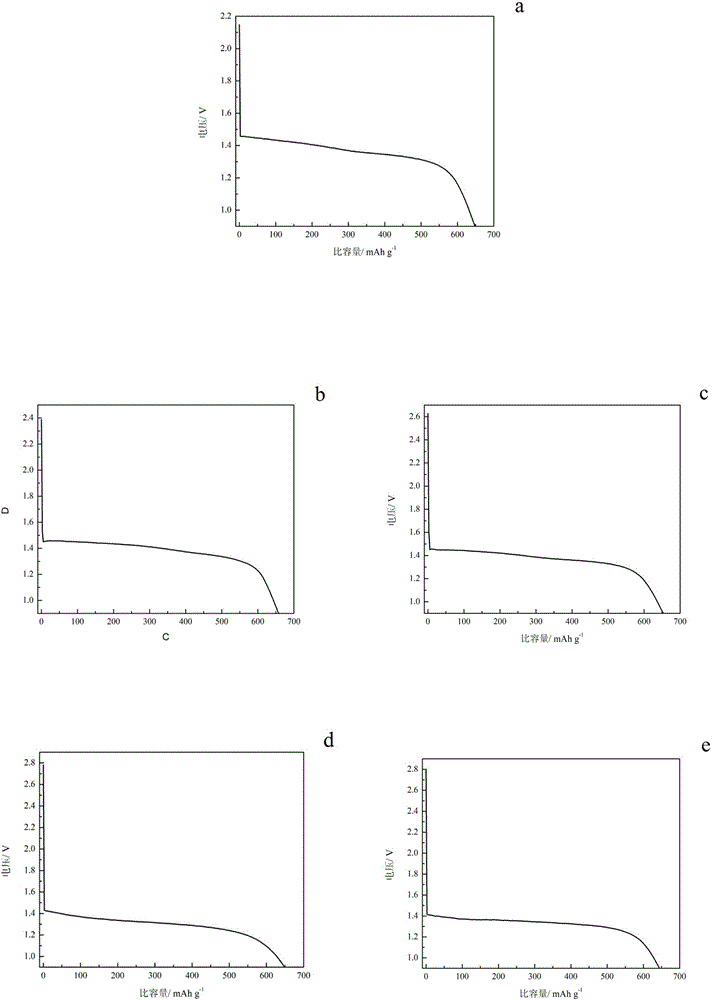

[0026] The present invention as figure 1 , 2 As shown, a preparation method of iron disulfide / carbon composite positive electrode material for primary lithium battery, carbon element is coated on the surface of iron disulfide particles, the mass percentage content of iron disulfide is 75%~99.5%, the mass percentage of carbon element Content is 0.5%~25%, it is characterized in that: specific steps are as follows:

[0027] (1) Mix pyrite and carbon source material according to the mass ratio of (75~95): (5~60), disperse in dispersant and ball mill for 1~10h to obtain a mixed paste; (2) mix The mixed paste obtained in step (1) was dried in a vacuum drying oven at 80-150°C for 1-10 hours, and the dried precursor material was heated to 300-500°C for 1-8 hours under the protection of an inert gas, and then cooled to After sieving at room temperature, the iron disulfide / carbon composite positive electrode material for primary lithium batteries was obtained. In this embodiment, the...

Embodiment 1

[0033] Embodiment 1: The mass percentage content of iron disulfide in the carbon-coated iron disulfide composite positive electrode material is 75%, and the mass percentage content of carbon element is 25%, and the specific steps are as follows:

[0034] (1) Mix pyrite and starch in a mass ratio of 75:60, disperse in an appropriate amount of aqueous solution and ball mill for 8 hours to obtain a mixed paste;

[0035] (2) Dry the mixed paste obtained in step (1) in a vacuum drying oven at 120°C for 5 hours. The dried precursor material is heated to 400°C for 5 hours under the protection of an inert gas, then cooled to room temperature, and sieved A granular iron disulfide / carbon composite cathode material for a primary lithium battery is obtained.

Embodiment 2

[0036] Embodiment 2: The mass percentage content of iron disulfide is 90%, and the mass percentage content of carbon element is 10%. The specific steps are as follows: (1) mix pyrite and sucrose in a mass ratio of 90:24, disperse them in an aqueous solution and ball mill them for 5 hours to obtain a mixed paste; (2) mix the mixed paste obtained in step (1) The material was dried in a vacuum oven at 120°C for 5h, and the dried precursor material was heated to 400°C for 8h under the protection of an inert gas, then cooled to room temperature, and sieved to obtain a primary lithium battery iron disulfide / carbon composite positive electrode material .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com