Negative electrode sheet of lithium ion battery, manufacturing method thereof, and manufacturing device thereof

A lithium-ion battery and manufacturing device technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, batteries, etc., can solve the problems of difficult to control the thickness of the metal lithium layer, hidden safety hazards for operators, and complicated handling of pole pieces. Efficiency, low environmental requirements, and simple device architecture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

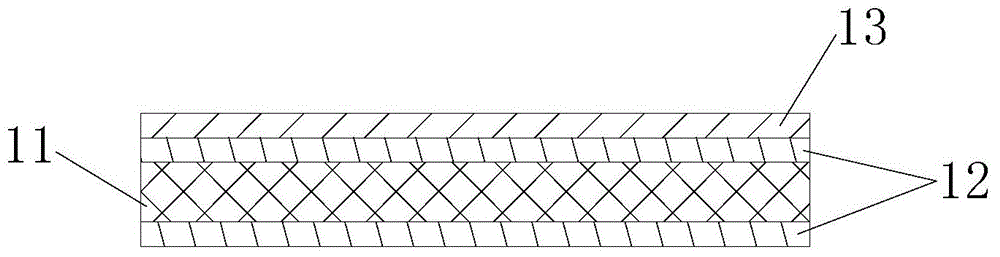

[0028] Such as figure 1 As shown, a negative electrode sheet of a lithium ion battery includes a negative electrode collector sheet 11, both surfaces of the negative electrode collector sheet are coated with active material layers 12, and an SEI film 13 is provided on the surface of one active material layer.

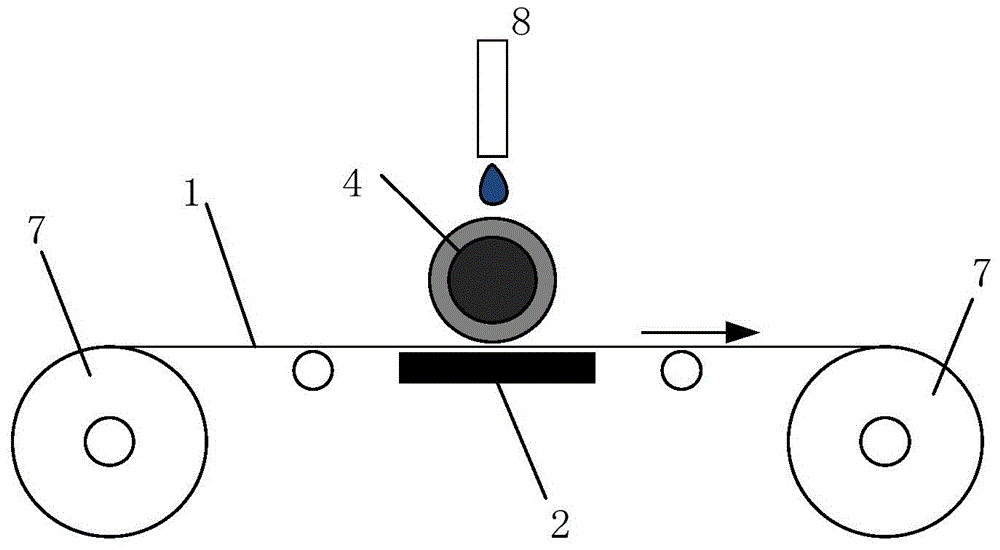

[0029] A method for manufacturing a negative electrode sheet of a lithium ion battery, comprising the following steps:

[0030] 1) Coating the surface of an active material layer containing lithium ions Li + The electrolyte solution, the primary electrode sheet includes a negative electrode collector sheet and an active material layer coated on both surfaces of the negative electrode collector sheet;

[0031] 2) Connect the positive terminal of the DC power supply to the electrolyte on the above-mentioned one active material layer, and connect the negative terminal of the DC power supply to the primary plate without contacting the electrolyte. Under the action of DC vo...

Embodiment 2

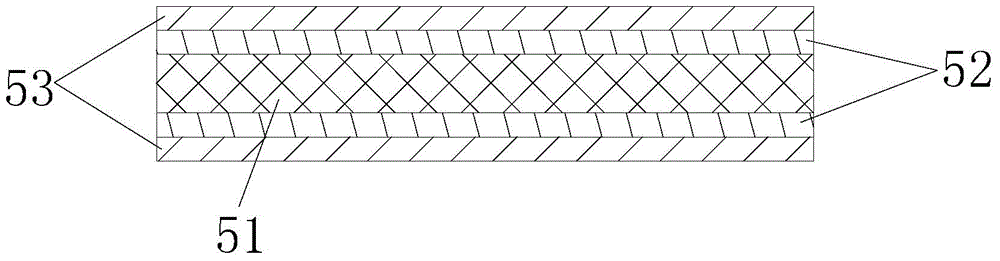

[0042] Such as image 3 As shown, a negative electrode sheet of a lithium ion battery includes a negative electrode collector sheet 51, both surfaces of the negative electrode collector sheet are coated with active material layers 52, and SEI films 53 are provided on the surfaces of both active material layers.

[0043] A method for manufacturing a negative electrode sheet of a lithium ion battery, comprising the following steps:

[0044] 1) Coating the surface of the two active material layers containing lithium ions Li + The electrolyte solution, the primary electrode sheet includes a negative electrode collector sheet and an active material layer coated on both surfaces of the negative electrode collector sheet;

[0045] 2) Connect the positive terminal of the DC power supply to the electrolyte on the two active material layers, and connect the negative terminal of the DC power supply to the primary electrode sheet without contacting the electrolyte. Under the action of DC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com