High-precision inner detecting device for seabed oil and gas pipeline flaws

A technology for oil and gas pipelines and detection devices, which is applied in the direction of special pipes, pipe components, pipes/pipe joints/pipes, etc., to achieve the effects of eliminating posture instability, simplifying the number and length of sections, and simple launch and recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

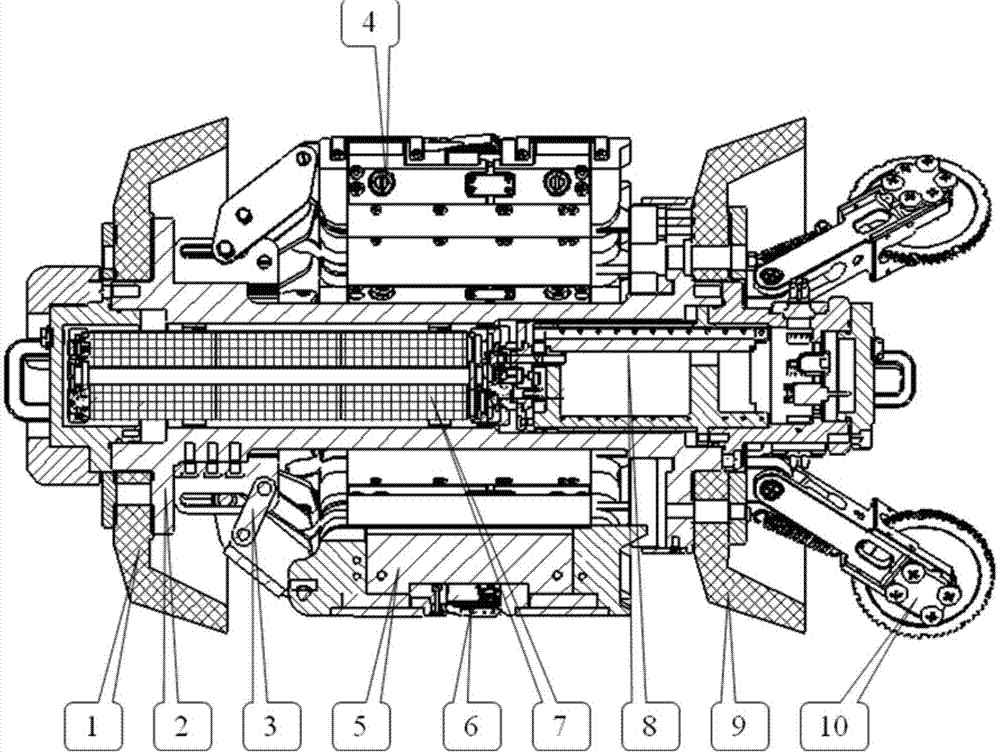

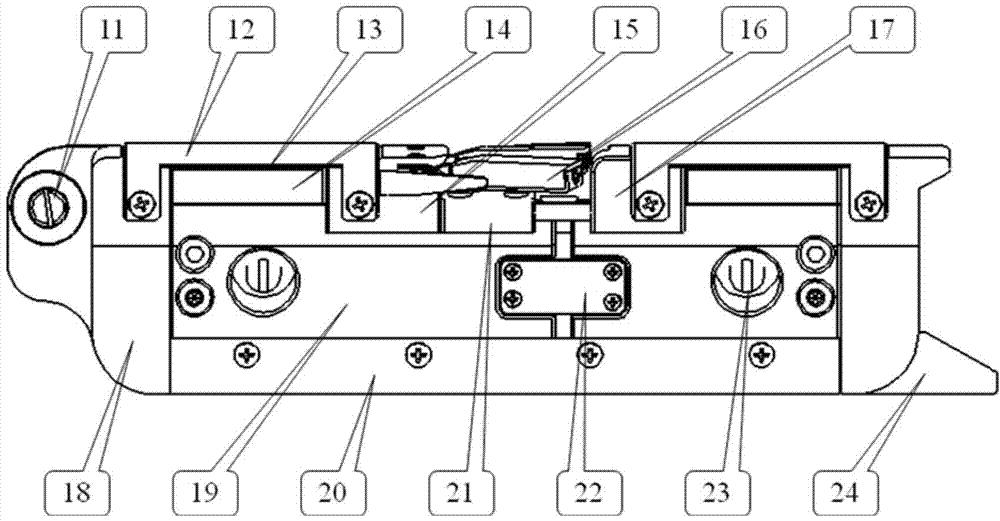

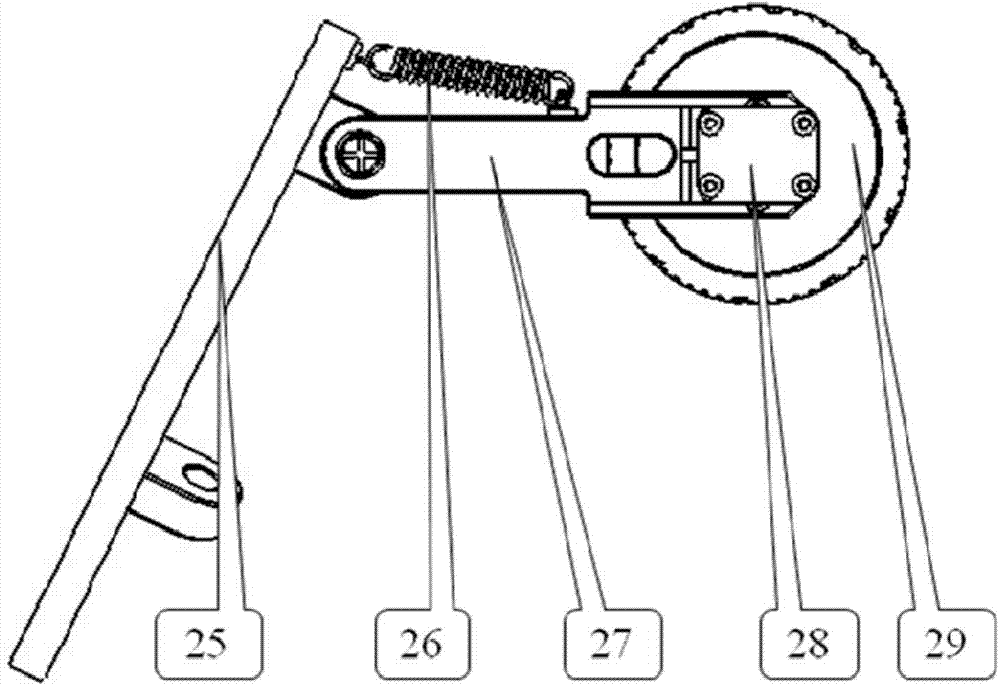

[0020] The present invention will be described in detail below in conjunction with accompanying drawings and embodiments, and an 18-inch (457 mm) floating submarine oil and gas pipeline defect high-precision internal detection device is used as an example for illustration.

[0021] The overall length of the 18-inch floating subsea oil and gas pipeline defect high-precision internal detection device is 871 mm, of which the length of the fixed body is 803 mm. The maximum diameter of the floating magnetization detection block 5 is 450 mm. The working diameter of the floating magnetization detection block 5 is 428 mm. The minimum shrinkage diameter of the detection block 5 is 320 mm, the maximum fixed body diameter of the detection device is 315 mm, and the overall weight of the detection device is 260 kg.

[0022] refer to figure 1 , The 18-inch floating subsea oil and gas pipeline defect high-precision internal detection device includes a body support shaft 2, which is supported...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com