An Electromagnetically Driven Non-Back Pressure Electronically Controlled Diesel Injector

A technology of electromagnetic drive and diesel fuel injector, which is applied in the direction of engine components, machines/engines, fuel injection devices, etc. It can solve the problems of high-frequency response characteristics of fuel injectors that are not good enough, difficult to respond to injection frequency, and not difficult to process. , to achieve the effects of improved technical indicators, low cost, and convenient processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

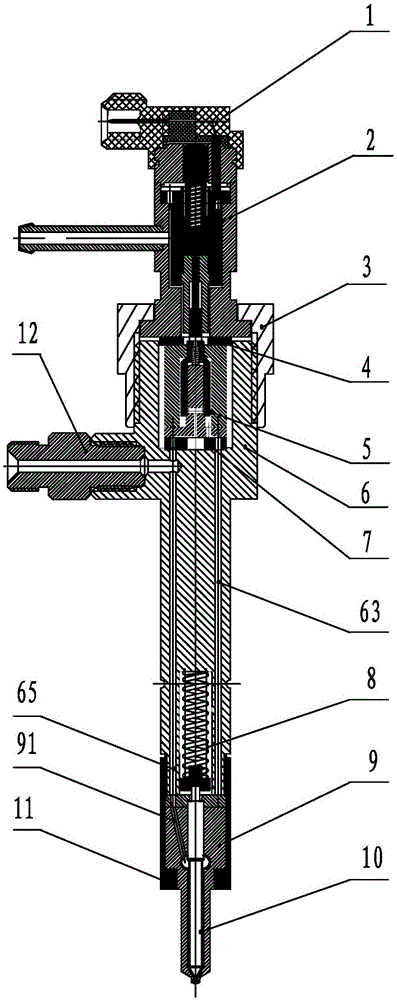

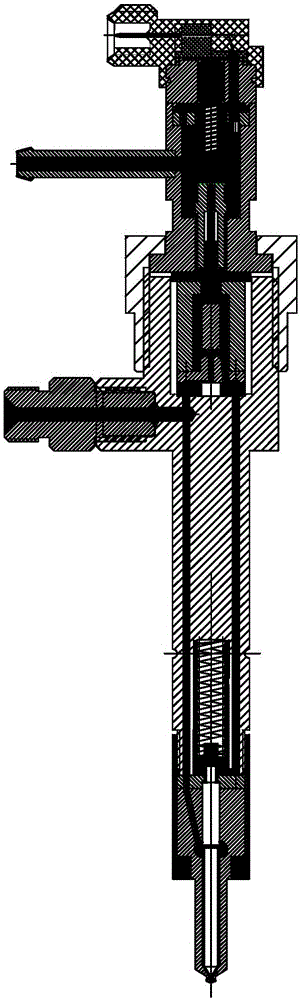

[0071] An electromagnetically driven non-backpressure electronically controlled diesel fuel injector, comprising a fuel injector housing 6 with an oil inlet channel and an oil return channel, a nut sleeve 11, an electromagnetic driver 2, a lock nut 3, an adjusting gasket 4, No back pressure two-position three-way valve 5, transition block 7, pressure spring 8, fuel injector assembly 9 and valve needle 10, install transition block 7 and no back pressure sequentially in the injector housing 6 along the axial direction Two-position three-way valve 5, adjusting gasket 4, lock nut 3, electromagnetic driver 2, the pressure spring 8 and the fuel injection nozzle coupler 9 are sequentially installed in the nut sleeve 11, the upper and lower end surfaces of the fuel injector housing 6, The transition block 7, the two-position three-way valve 5 without back pressure, the two end faces of the adjusting gasket 4, and the lower end face of the electromagnetic driver 2 are high-flatness plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com