Liquid-injecting method of battery and liquid-injecting production line thereof

A production line and liquid injection technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve problems such as error identification, affecting work efficiency, and low work efficiency, and achieve the effects of accurate weighing and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

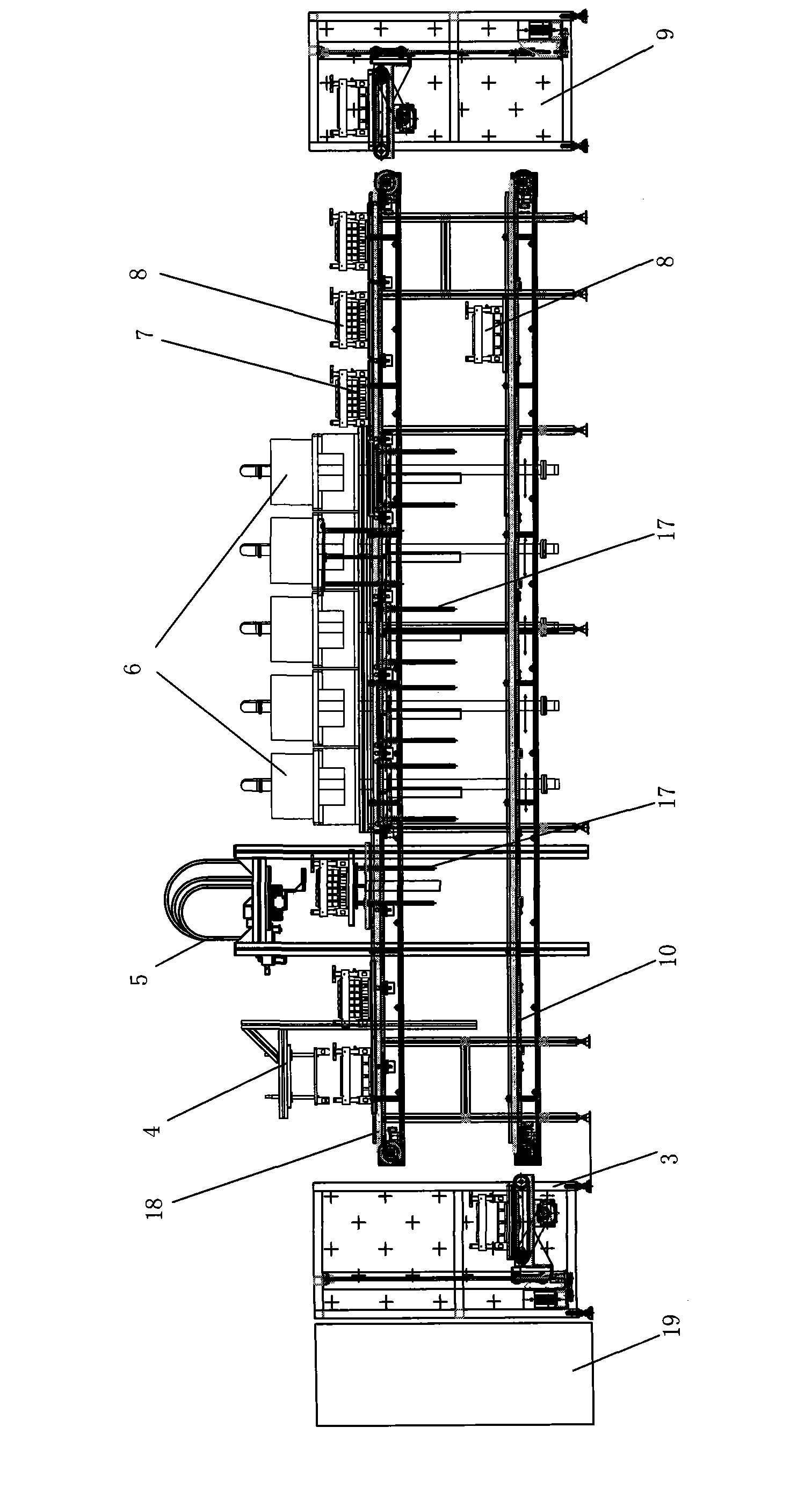

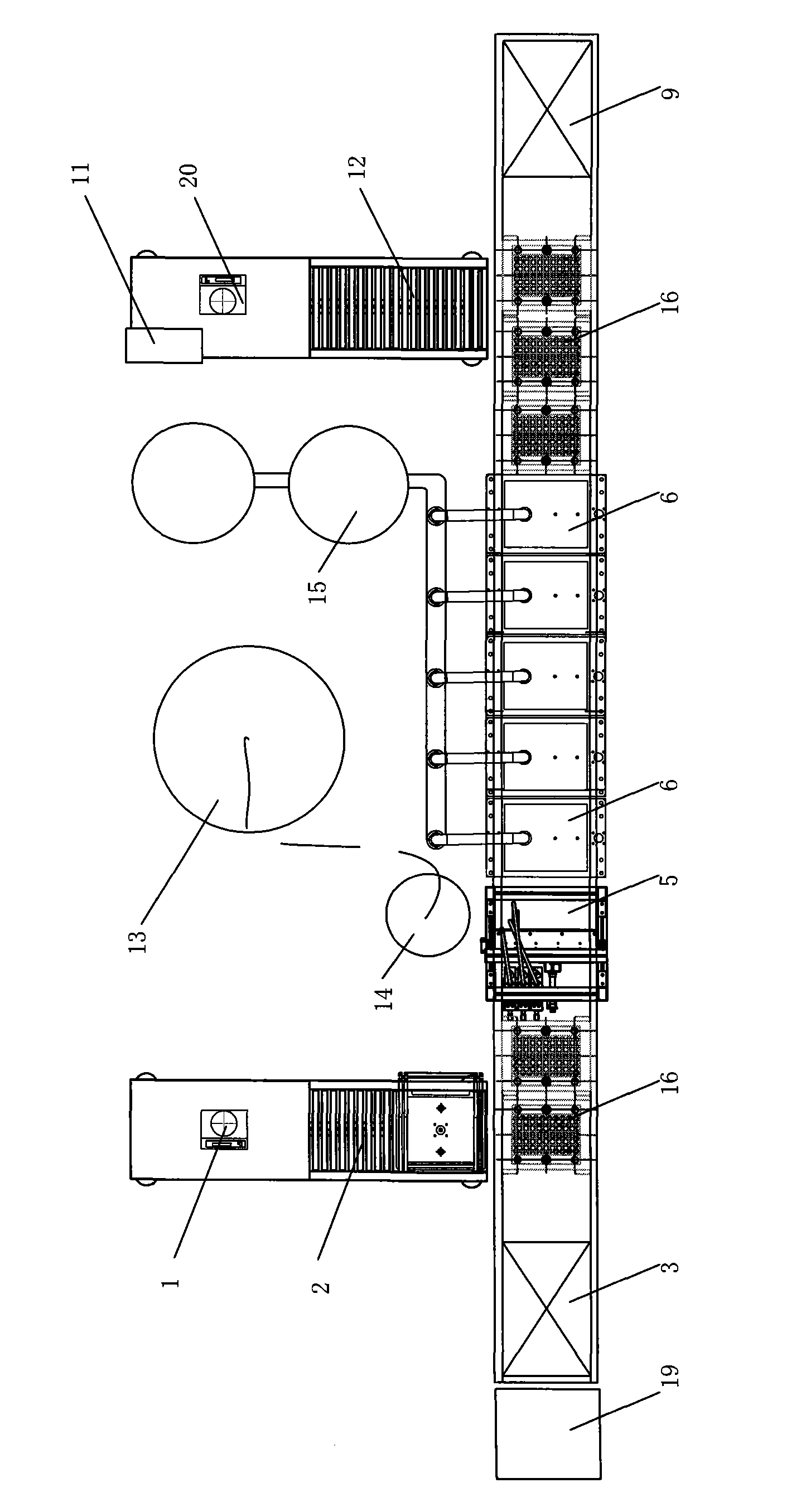

[0021] Such as figure 1 and figure 2 A battery liquid injection production line shown includes a frame, a liquid injection conveying line 18 and a tray conveying line 10. The liquid injecting conveying line 18 and the tray conveying line 10 pass through the frame, wherein the liquid injecting conveying line 18 is located on the tray conveying line 10 above. The frame is successively provided with a tray pressing device 4, a liquid injection device, and a vacuuming device. Also be provided with front working platform, rear working platform and control box 19.

[0022] The front working platform is provided with a front electronic scale 1 and a front hand-push conveying line 2. The front electronic scale 1 is used to weigh the weight of the unfilled cell. The control box 19 is equipped with a control module PLC. The front electronic scale 1 weighs After weighing, the obtained weight value is sent to the control module for storage and memory. The rear working platform is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com