Back-pressure exhausting pipe capable of generating power

An exhaust pipe and generator technology, which is applied to exhaust devices, engine components, combustion engines, etc., can solve the problem of poor engine power and emissions, hindering the exhaust of automobile exhaust pipes, and hindering the smooth flow of exhaust gas, etc. problems, to achieve the effects of improving power performance, increasing airflow resistance, and increasing intermittent negative pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

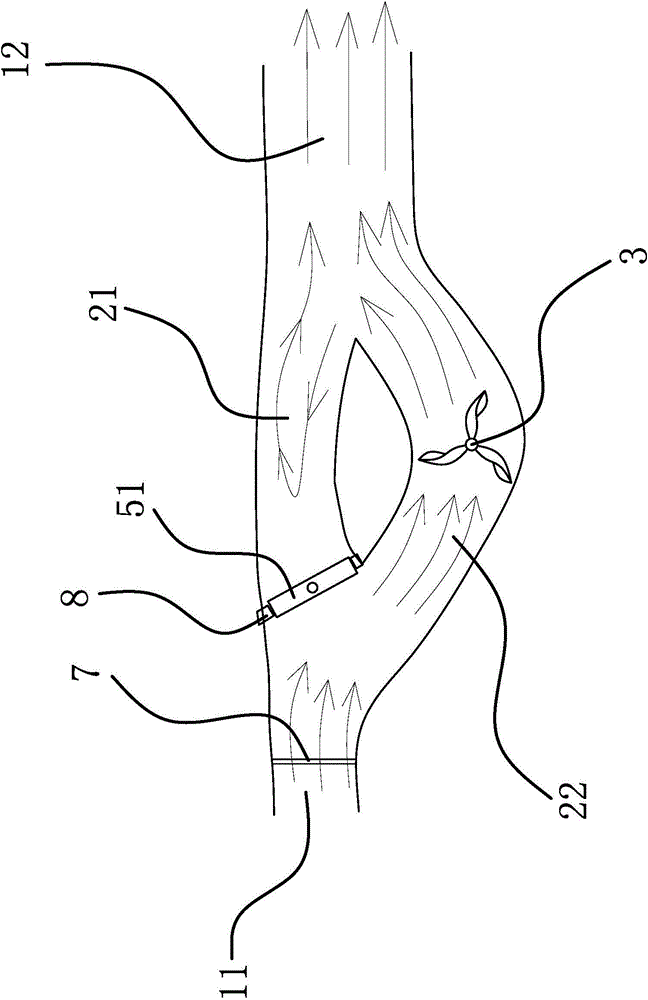

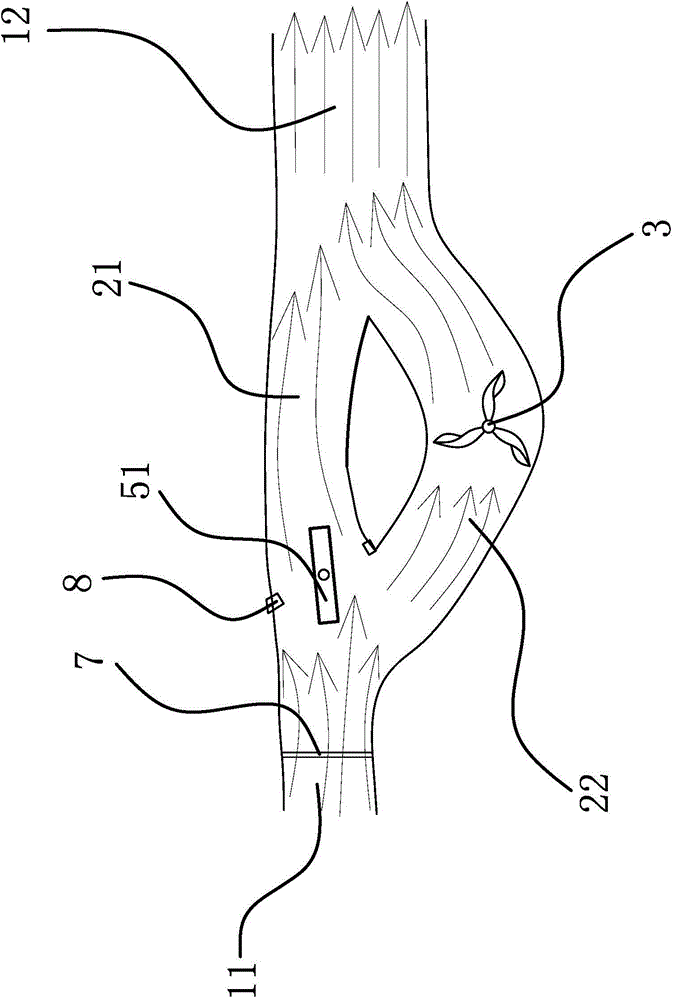

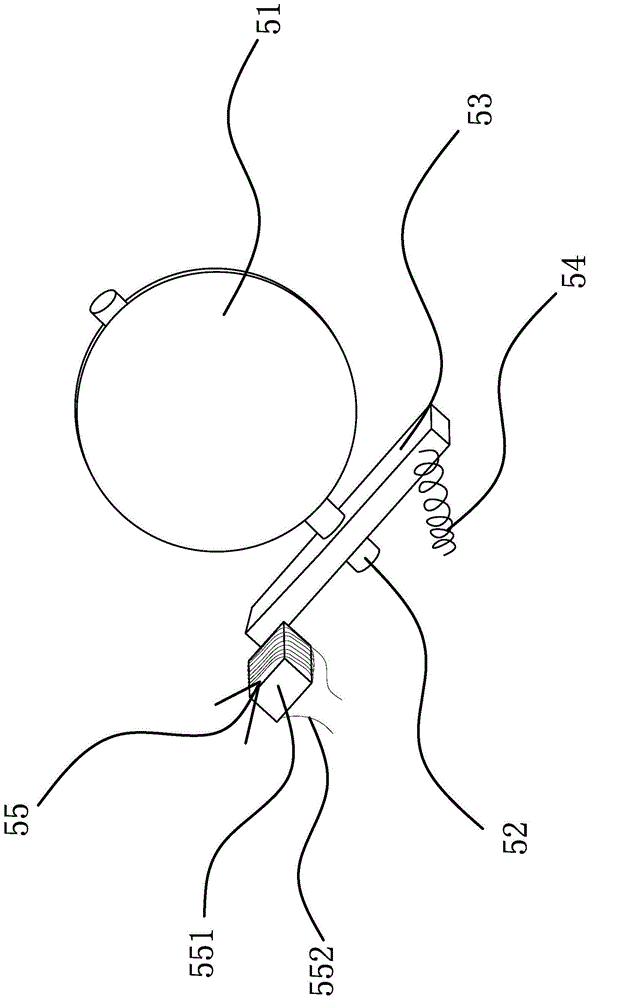

[0025] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5As shown, a back pressure exhaust pipe that can generate electricity, the back pressure exhaust pipe includes a front pipe body 11 connected to the engine, a rear pipe body 12 connected to the muffler, a manifold one 21 and a manifold two 22, The inlets of manifold one 21 and manifold two 22 are all connected with the outlet of front section pipe body 11, and the outlets of manifold one 21 and manifold two 22 are all connected with the entrance of rear section pipe body 12, and inside manifold one 21 An impeller 3 is provided, and the impeller 3 is connected with a generator 4. A gate 51 capable of closing the entrance of the manifold two 22 is arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com