Preparation method of high comfort triangular hollow microporous fiber

A microporous, triangular technology, applied in the manufacture of hollow filaments, fiber treatment, melting of filament raw materials, etc., can solve the problem of less hollow microporous fibers, etc., and achieve simple production process, excellent gloss, excellent moisture absorption and quick drying performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

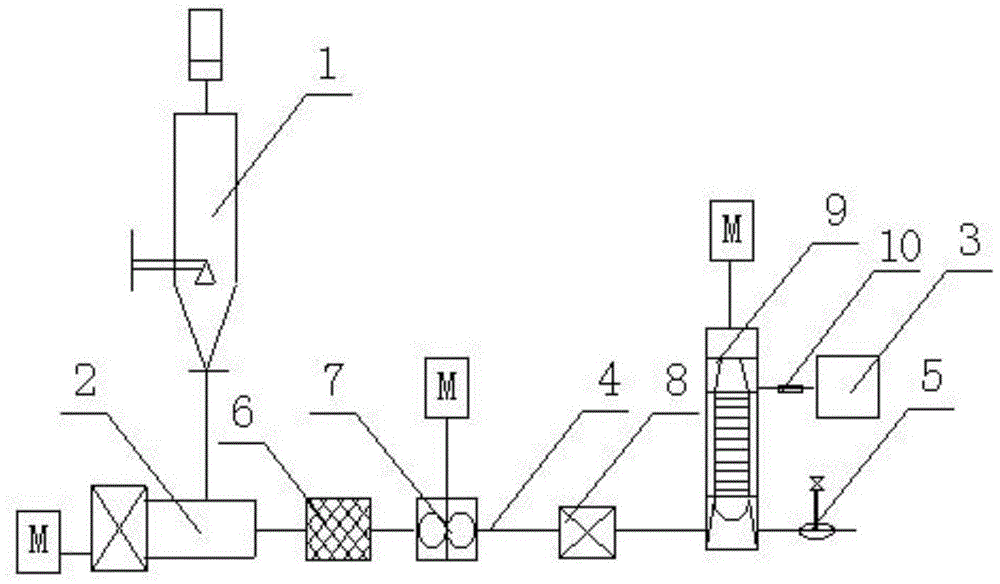

[0021] like figure 1 As shown, the preparation method of the high-comfort triangular hollow microporous polyester fiber described in this embodiment, the steps are as follows:

[0022] The first step, preparation of masterbatch and polyester melt: polymerize sodium isophthalic acid sulfonate with terephthalic acid and ethylene glycol, and the resulting product is a microporous masterbatch, in which isophthalic acid sulfonate The sodium content is 25%; purified terephthalic acid (PTA) and ethylene glycol (EG) undergo esterification, precondensation, and final polymerization to obtain a polyester melt, wherein the esterification temperature is 270°C, and the precondensation temperature is 289°C , the final polycondensation temperature is 289°C, and the obtained polyester melt viscosity is 0.625dl / g;

[0023] The second step is the preparation of hollow microporous polyester fibers with triangular cross-section: the masterbatch is dried by the masterbatch dryer 1, extruded and m...

Embodiment 2

[0030] like figure 1 As shown, the preparation method of the high-comfort triangular hollow microporous polyester fiber described in this embodiment, the steps are as follows:

[0031] The first step, preparation of masterbatch and polyester melt: polymerize sodium isophthalic acid sulfonate with purified terephthalic acid and ethylene glycol, and the resulting product is a microporous masterbatch, in which isophthalic acid sulfonate The sodium content is 25%; purified terephthalic acid (PTA) and ethylene glycol (EG) undergo esterification, precondensation, and final polymerization to obtain a polyester melt, wherein the esterification temperature is 270°C, and the precondensation temperature is 289°C , the final polycondensation temperature is 289°C, and the obtained polyester melt viscosity is 0.625dl / g;

[0032] The second step is the preparation of hollow microporous polyester fibers with triangular cross-section: the masterbatch is dried by the masterbatch dryer 1, extru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com