Rubber powder asphalt and preparation method thereof

A technology of rubber powder and asphalt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

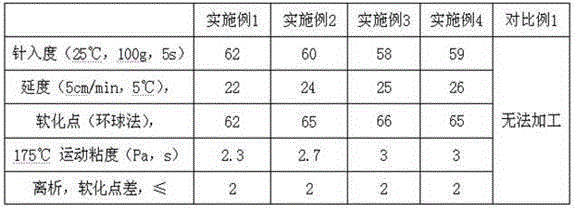

Examples

Embodiment 1

[0025] A rubber powder asphalt, comprising the following components in mass percentage: 35% of rubber powder, 0.3% of B-450 high-efficiency activator, 2% of lignosulfonate, and the balance being base asphalt.

[0026] The above base asphalt is No. 70 heavy traffic road petroleum asphalt; the particle size of the rubber powder is 30 mesh, the ash content is less than 10%, and the sieve residue is less than 8%.

[0027] The preparation method is as follows: according to the above mass percentage, heat the base asphalt to 180 ° C ~ 190 ° C, add 20% rubber powder and 0.3% B-450 high-efficiency activator under stirring; then use a colloid mill for the first grinding, Then enter another colloid mill for the second grinding, and grind for the second time until the average particle size of the rubber powder is 0.1-0.3 mm; then add 2% lignosulfonate under stirring, and then add 15% rubber powder; Grind for the third time with a colloid mill until the average particle size of the rubber...

Embodiment 2

[0029] A rubber powder asphalt, comprising the following components in mass percentage: 38% of rubber powder, 0.3% of B-450 high-efficiency activator, 3% of lignosulfonate, and the balance being base asphalt.

[0030] The above base asphalt is No. 70 heavy traffic road petroleum asphalt; the particle size of the rubber powder is 50 mesh, the ash content is less than 10%, and the sieve residue is less than 8%.

[0031] The preparation method is as follows: according to the above mass percentage, heat the base asphalt to 180 ° C ~ 190 ° C, add 20% rubber powder and 0.3% B-450 high-efficiency activator under stirring; then use a colloid mill for the first grinding, Then enter another colloid mill for the second grinding, and grind for the second time until the average particle size of the rubber powder is 0.1-0.3 mm; then add 3% lignosulfonate under stirring, and then add 18% rubber powder; Grind for the third time with a colloid mill until the average particle size of rubber pow...

Embodiment 3

[0033] A rubber powder asphalt, comprising the following components in mass percentage: 40% of rubber powder, 0.3% of B-450 high-efficiency activator, 5% of lignosulfonate, and the balance being base asphalt.

[0034] The above base asphalt is No. 70 heavy traffic road petroleum asphalt; the particle size of the rubber powder is 40 mesh, the ash content is less than 10%, and the sieve residue is less than 8%.

[0035] The preparation method is as follows: according to the above mass percentage, heat the base asphalt to 180 ° C ~ 190 ° C, add 20% rubber powder and 0.3% B-450 high-efficiency activator under stirring; then use a colloid mill for the first grinding, Then enter another colloid mill for the second grinding, and grind for the second time until the average particle size of the rubber powder is 0.1-0.3 mm; then add 5% lignosulfonate under stirring, and then add 20% rubber powder; Grind for the third time with a colloid mill until the average particle size of the rubber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com