Material for manufacturing wet tissues for wiping transparent glassy hard surface and preparation method thereof

A technology of wet wipes and surface density, applied in chemical instruments and methods, cellulose plastic material layered products, lamination devices, etc., can solve the problems of increasing processes and costs, affecting product performance, and having water stains, etc. To reduce the residue of water stains, improve the wiping effect, and retain moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

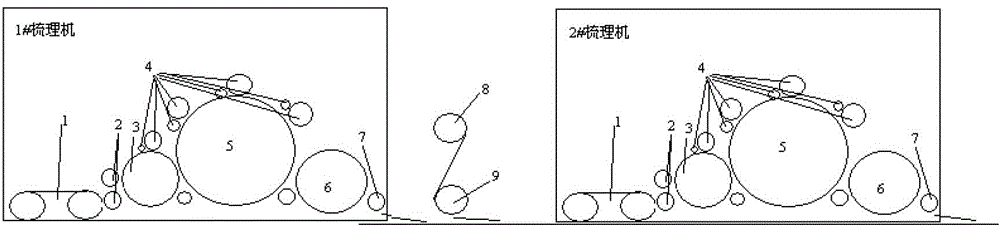

[0041] (1) if figure 1 As shown, the polyethylene / polypropylene sheath-core bicomponent fiber with a length of 60 mm, a fineness of 6 denier, and hydrophilic treatment was first opened and mixed, and then sent to 1# and 2# for carding through the cotton feeding curtain 1 respectively. The feeding roller 2 of the machine is repeatedly combed into a web through the chest cylinder 3, the main cylinder 5 and the carding unit 4 in sequence, and finally the fiber web is stripped into upper and lower layers of fiber webs by the doffer 6 and the stripping roller 7.

[0042] The 1# and 2# carding machines used are double-cylinder single-doffer structures, and each doffer is equipped with stripping rollers 7; The forest 5 rotating speed is 950 m / min, and the peeling roller 7 rotating speed is 35 m / min; 2 .

[0043] (2) Set the gram weight to 50g / m 2 The absorbent layer is unwound from the unwinding device 8 between 1# and 2# carding machines, and fed through the active feeding ro...

Embodiment 2

[0047] (1) if figure 1 As shown, the polyethylene / polypropylene sheath-core bicomponent fiber with a length of 50 mm, a fineness of 4.5 denier, and a hydrophilic treatment is firstly opened and mixed, and then fed into 1# and 2# respectively through the cotton feeding curtain 1 The carding machine, through the chest cylinder 3, the main cylinder 5 and the carding unit 4, is repeatedly carded into a web, and finally the fiber web is stripped into upper and lower layers of fiber webs by the doffer 6 and the stripping roller 7. The 1# and 2# carding machines adopted are double-cylinder single-doffer structures, and each doffer is equipped with stripping rollers 7; The 5 rotating speed is 1100 m / min, and the peeling roller 7 rotating speed is 50 m / min; 2 .

[0048] (2) Set the gram weight to 20g / m 2 The absorbent layer is unrolled from the unwinding device 8 between 1# and 2# carding machines, and fed through the active feeding roller 9, and the rotating speed of the unwinding ...

Embodiment 3

[0052] (1) if figure 1 As shown, the polyethylene / polypropylene sheath-core bicomponent fiber with a length of 45mm, a fineness of 3 denier, and a hydrophilic treatment is firstly opened and mixed, and then fed into 1# and 2# respectively through the cotton feeding curtain 1 The carding machine, through the chest cylinder 3, the main cylinder 5 and the carding unit 4, is repeatedly carded into a web, and finally the fiber web is stripped into upper and lower layers of fiber webs by the doffer 6 and the stripping roller 7. The 1# and 2# carding machines adopted are double-cylinder single-doffer structures, and each doffer is equipped with stripping rollers 7; the speed of the chest cylinder 3 of the two carding machines is 480m / min, and the main cylinder The 5 rotating speed is 1250 m / min, and the peeling roller 7 rotating speed is 60 m / min; 2 .

[0053] (2) Set the gram weight to 30g / m 2 The absorbent layer is unwound from the unwinding device 8 between 1# and 2# carding ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com