Riveting method of ultrahigh strength steel plates or aluminum alloy plates

An ultra-high-strength, aluminum alloy plate technology, which is applied in the field of riveting between ultra-high-strength steel plates or with aluminum alloy plates, and in the processing of metal plates, to achieve the effect of realizing connections and avoiding cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

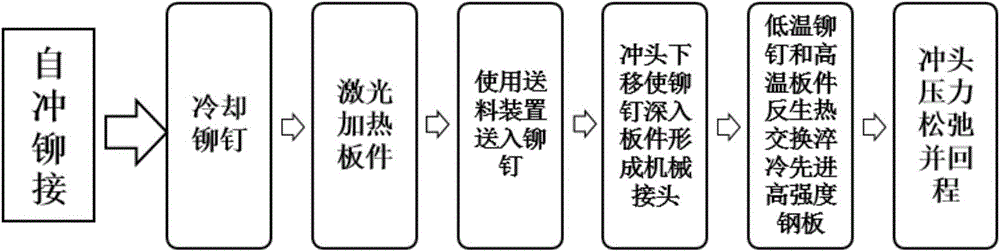

[0093] When both the upper panel 2 and the lower panel 3 are ultra-high-strength steel plates, the steps of the self-piercing riveting method between the ultra-high-strength steel plates or the riveting method with the aluminum alloy plate of the present invention are as follows:

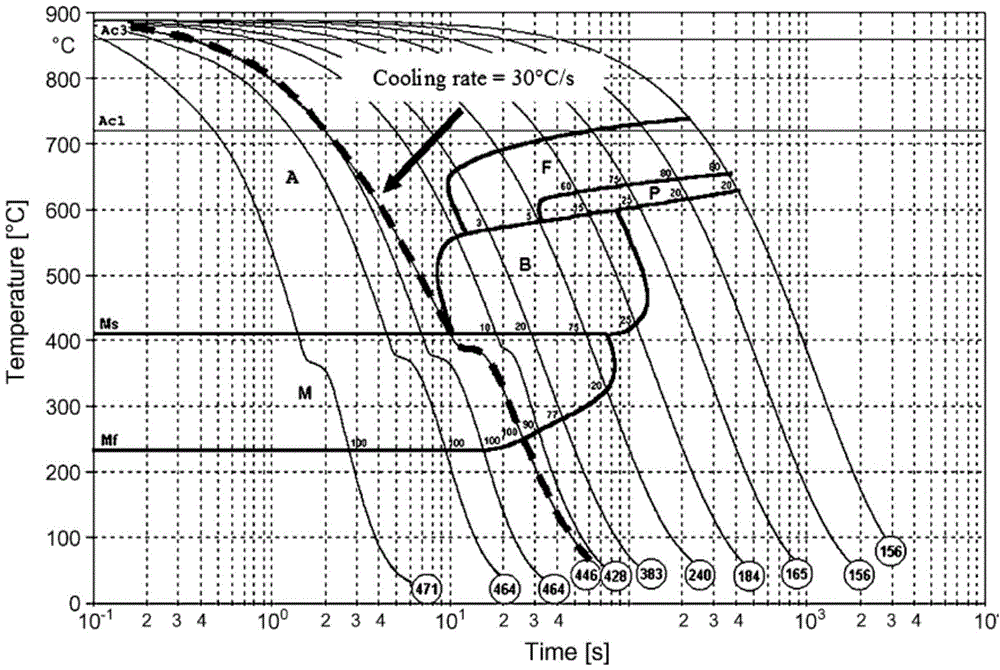

[0094] 1. Before self-piercing riveting, first cool the rivet 1 with liquid nitrogen in the cooling room, and lower the temperature of the rivet 1 to 0°C, so that the riveting connection of the rivet 1 to the upper sheet 2 and the lower sheet 3 during riveting The region undergoes rapid quenching.

[0095] 2. Place the upper panel 2 and the lower panel 3 to be riveted on the first composite die 5, and drive the first composite blank holder 4 to move down to compress the upper panel 2 and the lower panel 3.

[0096] 3. The first optical fiber heater 7 heats the upper sheet 2, and the first optical fiber heater 7 is aimed at the riveted connection area on the upper surface of the upper sheet 2 for loc...

Embodiment 2

[0102] In the case where the material is the upper plate 2 of the aluminum alloy plate and the material is the lower plate 3 of the ultra-high-strength steel plate, the self-piercing riveting method between the high-strength steel plates or the riveting method with the aluminum alloy plate of the present invention The steps are as follows:

[0103] 1. Before self-piercing riveting, the rivet 1 is first cooled with liquid nitrogen in the cooling chamber to lower its temperature to 0°C, so that the riveting connection area between the upper sheet 2 and the lower sheet 3 is fixed by the rivet 1 during riveting. Rapid quenching.

[0104] 2. Place the upper panel 2 and the lower panel 3 on the first composite die 5, and drive the first composite blank holder 4 to move down to compress the upper panel 2 and the lower panel 3.

[0105] 3. The first optical fiber heater 7 heats the upper plate 2, that is, the first optical fiber heater 7 is aligned with the riveted connection area on...

Embodiment 3

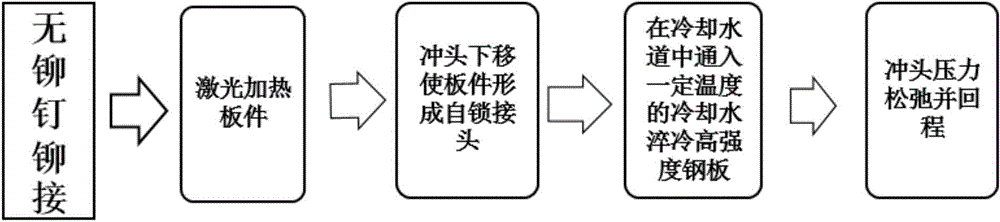

[0111] For the case where the materials of the upper panel 2 and the lower panel 3 are ultra-high-strength steel plates, the steps of the riveting method without rivets in the riveting method between the ultra-high-strength steel plates or with the aluminum alloy plate of the present invention are as follows:

[0112] 1. Place the upper panel 2 and the lower panel 3 on the second composite die 11, and drive the second composite blank holder 10 to move down to compress the upper panel 2 and the lower panel 3.

[0113] 2. The third optical fiber heater 13 heats the upper sheet 2, that is, the third optical fiber heater 13 is aimed at the riveted connection area on the upper surface of the upper sheet 2 for local concentrated heating. For the upper plate 2 made of high-strength steel plate, adjust the power of the third optical fiber heater 13 to 1KW, heat the riveted connection area of the upper plate 2 to 950°C, and heat the The sensitive resistor 9 measures the temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com