Hollow partition plate stationary blade profile correcting method

A technology of hollow baffles and stator blades, which is applied in the processing field of hollow baffle-type stator blades, and can solve problems such as secondary deformation of blades and poor correction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

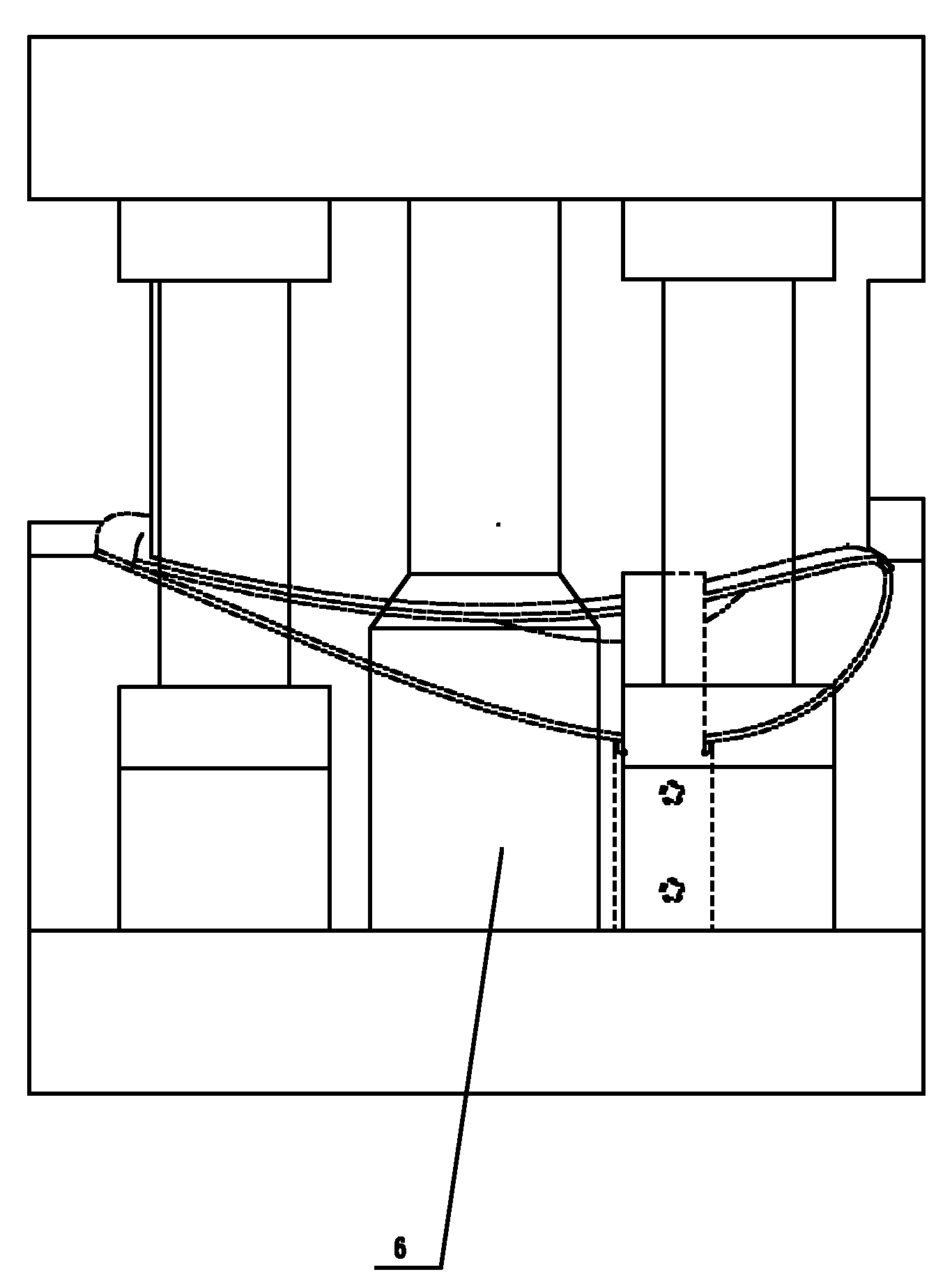

[0011] A method for correcting the profile of a hollow partition-type stationary vane, which includes mold correction, installing the correction mold on a press, filling the cavity of a hollow partition-type stationary vane 5 with a filling material 4 before the mold correction, See figure 2 , and then place the blade in the calibration mold, apply pressure to the calibration mold with a press, and perform mold calibration on the blade profile. After the calibration is completed, the filling material inside the blade cavity is removed, and the blade can enter the subsequent processing procedure.

[0012] The filling material is paraffin. Before the blade mold is corrected, use a wax melting box to fill the paraffin in the molten state inside the blade cavity. After the paraffin in the blade cavity is fully cooled and solidified, place the blade in the calibration mold for mold calibration. Clean the residual paraffin on the surface of the blade before the mold is calibrated. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com