A kind of preparation method of epoxy microcapsule with phenolic resin as wall material

A technology of phenolic resin and microcapsules, which is applied in the field of preparation of epoxy microcapsules, can solve problems such as the difficulty of epoxy microcapsules, and achieve the effect of good shape, low price and high coating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

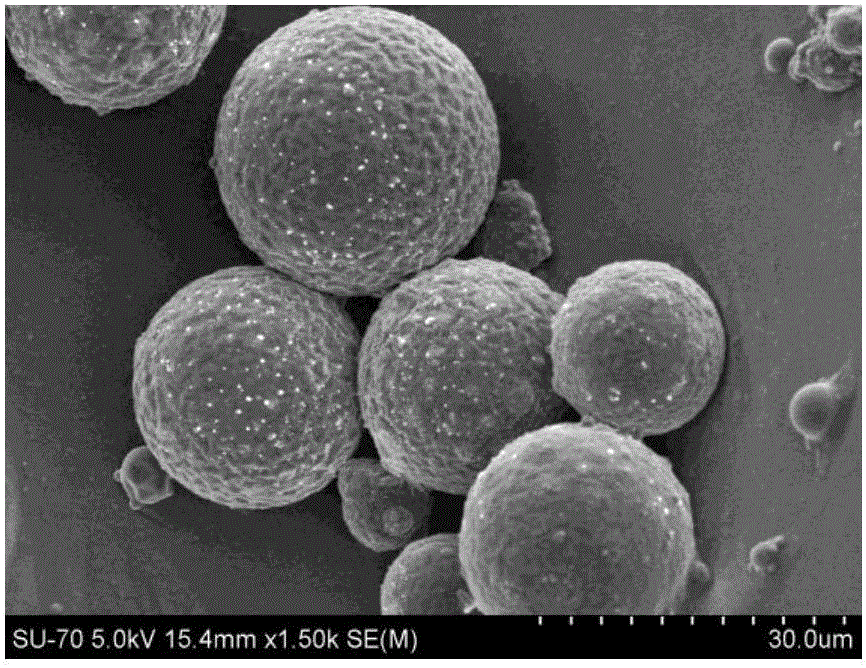

Image

Examples

preparation example Construction

[0014] The technical solution adopted by the present invention to solve the above-mentioned technical problems is to provide a kind of preparation method of epoxy microcapsules with phenolic resin as wall material, comprising the following steps:

[0015] S1: Mix epoxy resin, emulsifier, and water, and stir to make emulsion;

[0016] S2: adding phenol, aldehyde and pH regulator I to the emulsion, adjusting the pH to 7-9, and stirring;

[0017] S3: Add polyhydric phenol, curing accelerator, and pH adjuster II to the solution obtained in step S2, adjust the pH to 2-4, react for 2-3 hours, cool, stand, filter, and dry to obtain the phenolic resin Epoxy microcapsules for wall materials.

[0018] Wherein, the emulsifier in step S1 is a polyhydroxy compound, at least one selected from polyvinyl alcohol, polypropylene alcohol, polysaccharides, and alkyl glycosides. Further, the mass ratio of epoxy resin, emulsifier, and water in step S1 is 1:0.05-0.2:10-30; in order to fully emulsi...

Embodiment 1

[0023] In a 250ml three-neck flask, add 10ml of 5wt% polyvinyl alcohol (PVA-1788) aqueous solution, 100ml of deionized water, stir well, then slowly add 2.1g (0.022mol) of phenol, and after it dissolves, use ammonia water (NH 3 ·H 2 O) Adjust the pH value of the solution to 7, then slowly add 6.5g of epoxy resin, stir and emulsify at high speed for 60min, and the rotation speed is greater than 1000rpm, to obtain a uniform and stable oil-in-water epoxy emulsion.

[0024] Adjust the rotation speed to 400rpm, and slowly add 3.35g (0.041mol) formaldehyde (CH 2 O) aqueous solution, and at the same time slowly raise the temperature to 65°C, and keep it warm for 3 hours to form a water-soluble Resole phenolic resin. Then adjust the pH value to 4 with 3.7% hydrochloric acid solution, add 0.5g resorcinol, react for 30min, then add 0.5g NH 4 Cl, continue to react for 2.5h to form epoxy microcapsules with phenolic resin as the wall material.

[0025] After the reaction solution is coo...

Embodiment 2

[0027] The process of embodiment 2 is basically the same as that of embodiment 1, except that the pH is adjusted to 8 at the stage of resole phenolic resin formation, and the pH is adjusted to 3 at the stage of crosslinking and curing. Specific steps are as follows:

[0028] In a 250ml three-neck flask, add 10ml of 5wt% polyvinyl alcohol (PVA) aqueous solution, 100ml of deionized water, stir well, then slowly add 2.1g (0.022mol) of phenol, and after it dissolves, use ammonia water (NH 3 ·H 2 O) Adjust the pH value of the solution to 8, then slowly add 6.5g of epoxy resin, stir and emulsify at high speed for 60min, and the rotation speed is greater than 1000rpm to obtain a uniform and stable oil-in-water epoxy emulsion.

[0029] Adjust the rotation speed to 400rpm, and slowly add 3.35g (0.041mol) formaldehyde (CH 2 O) aqueous solution, and at the same time slowly raise the temperature to 65°C, and keep it warm for 3 hours to form a water-soluble Resole phenolic resin. Then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com