Material handling apparatus

A material loading and unloading, hopper technology, applied in loading/unloading, conveyor control devices, packaging, etc., can solve problems such as slow sales of meat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

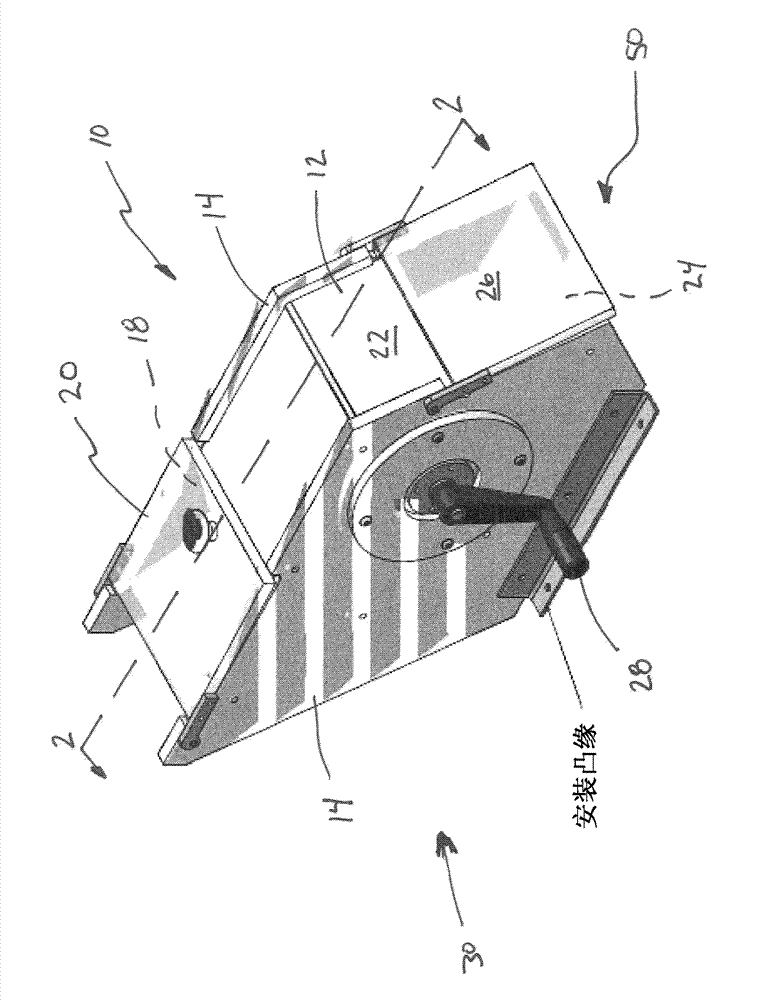

[0025] The present invention relates to material handling devices, and more particularly to handling devices for articles having a ferromagnetic composition. The inventors have found that the present invention is particularly useful for handling sachets or bags containing metal powder, and more particularly iron powder. However, it will be appreciated that the present disclosure is not limited to handling such packets or bags. In those embodiments described below where a magnet is used to move an object, the object may take any form but should include some ferromagnetic content and thus be attracted to the magnet. Several of the embodiments described below can also be used to handle items that do not have ferromagnetic properties, and in fact some embodiments do not include magnets.

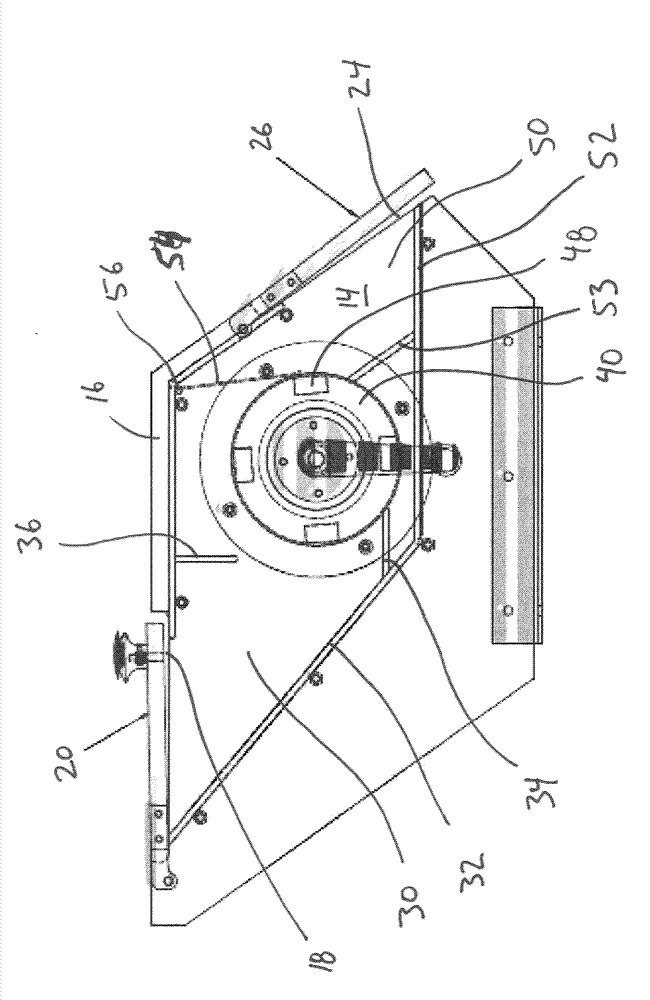

[0026] figure 1 One embodiment of the disclosure is illustrated. in particular, figure 1 A material handling device 10 is shown consisting generally of a body 12 . The body 12 includes oppos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com