Experiment device for simulating retention of in-pile melts obtained by melting of reactor core of nuclear reactor and experiment method

A technology for nuclear reactors and experimental devices, applied in the field of experimental devices, can solve the problems of inconvenient lifting and lowering of hemispherical copper shells, inability to study water flow, etc., and achieve the effects of improving sealing effect, enhancing safety, and reducing uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

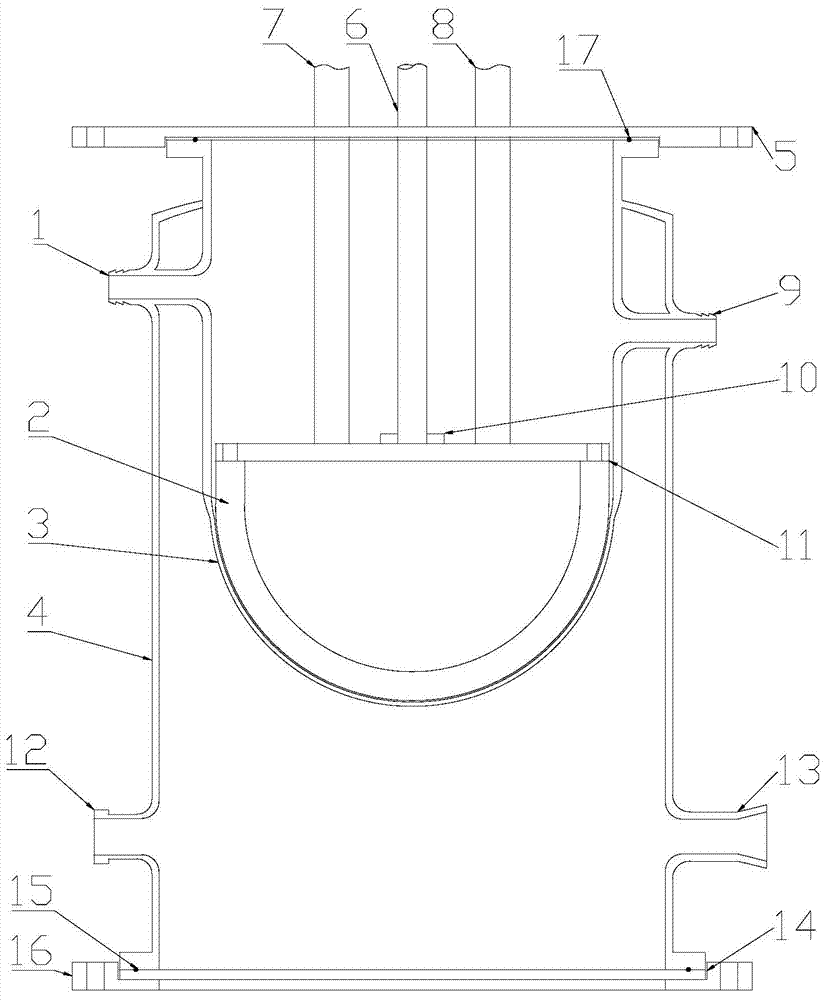

[0032] The present invention is described in further detail below in conjunction with accompanying drawing:

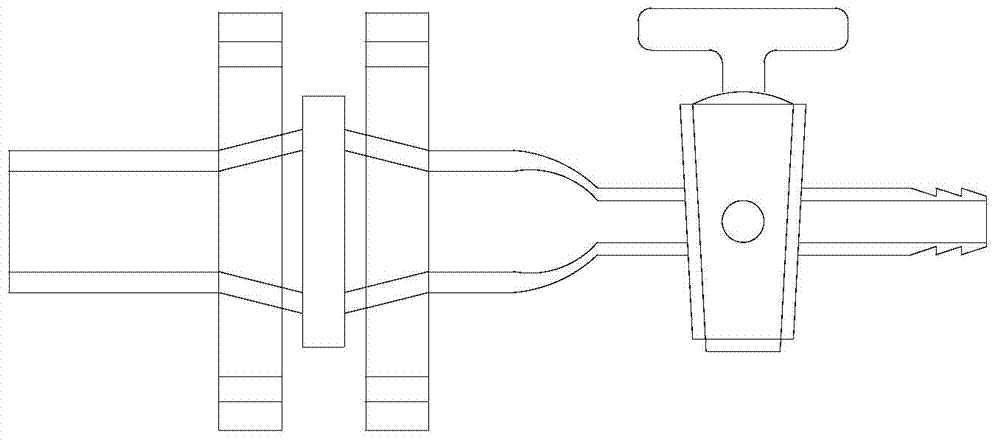

[0033] see Figure 1 to Figure 7 , the present invention is an experimental device for simulating the retention of molten matter in the nuclear reactor core after melting, including a quartz glass cylinder, a heating device and a data measurement system.

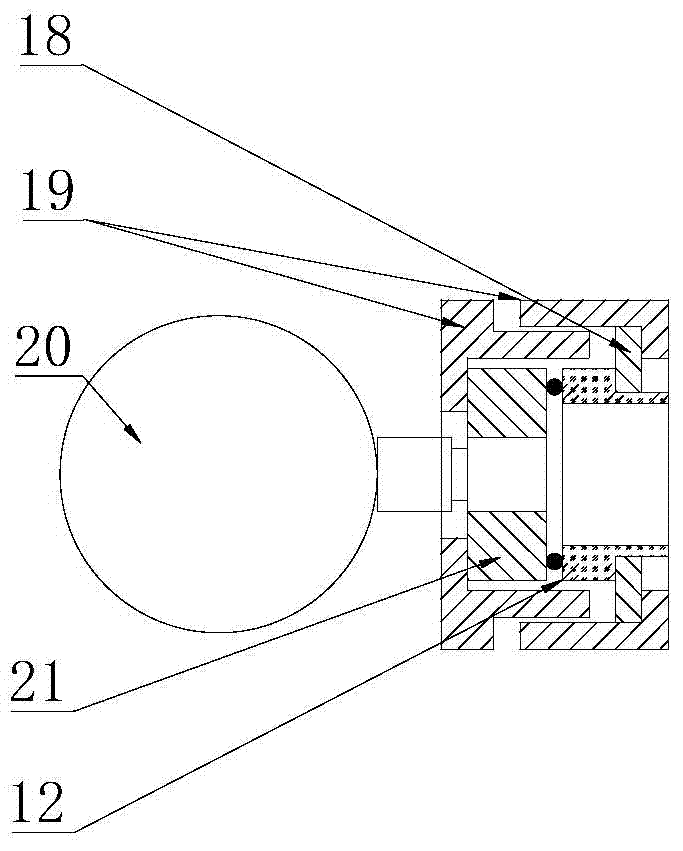

[0034] The quartz glass cylinder includes an inner hemispherical experimental section 3 and an outer vertical glass cylinder 4. The upper part of the hemispherical experimental section 3 and the vertical glass cylinder 4 are integrated by welding, so there is no need to provide additional support and sealing for the glass assembly. The side wall of the upper part of the vertical glass cylinder 4 is provided with the entrance 1 of the experimental section, and the wall of the opposite vertical glass cylinder 4 is provided with the outlet 9 of the experimental section. The entrance 1 of the experimental section and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com