Grating speed measurement method and device

A speed measurement and grating technology, applied in the field of grating Moiré fringe subdivision technology, can solve problems such as the inability to realize speed measurement, and achieve good linearity, increase the number of subdivisions, and achieve good pixel uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

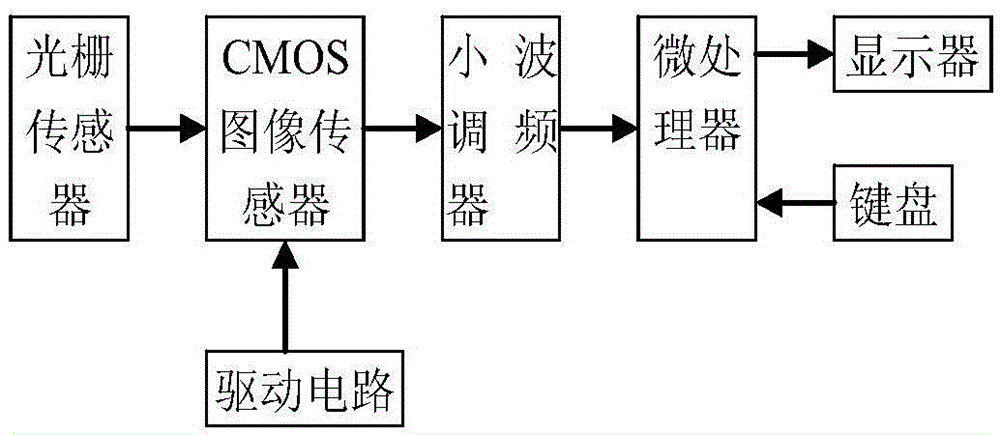

[0035] Specific embodiments: the patent of the present invention will be further described below in conjunction with the accompanying drawings:

[0036] A grating speed measurement method, using CMOS to collect the Moiré fringe light intensity signal of the grating sensor, and modulate it to the frequency of the wavelet base, and then perform wavelet transformation on the modulated signal to determine the frequency value corresponding to the largest ridge, according to the frequency value Then calculate the velocity value, the steps of this method are as follows:

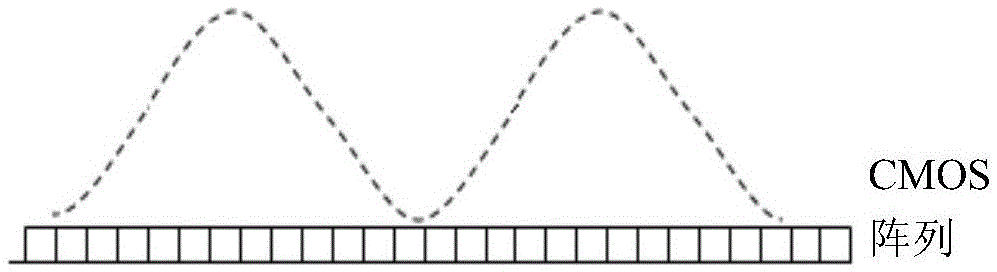

[0037] ① Extract two grating signals with a difference of 90° in CMOS

[0038] A complex number is composed of two orthogonal grating signals: U(x)=U c (x)+jU s (x),

[0040] The wavelet basis function can be optional. When the complex Shannon wavelet basis function is selected, the output signal of the grating sensor is modulated by the complex Shannon wavelet basis function is to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com