Micro light emitting diode display system

A micro-light-emitting diode and display system technology, applied in static indicators, instruments, semiconductor devices, etc., can solve the problems of difficult to reduce the number of row/column drivers, low pixel resolution, difficult to reduce the number, etc., and achieve low speed and energy consumption , high pixel resolution, reduced number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0111] Reference will now be made in detail to the exemplary embodiments of the present invention, examples of which are illustrated in the accompanying drawings. Elements / components with the same or similar numbers used in the drawings and the embodiments are used to represent the same or similar parts.

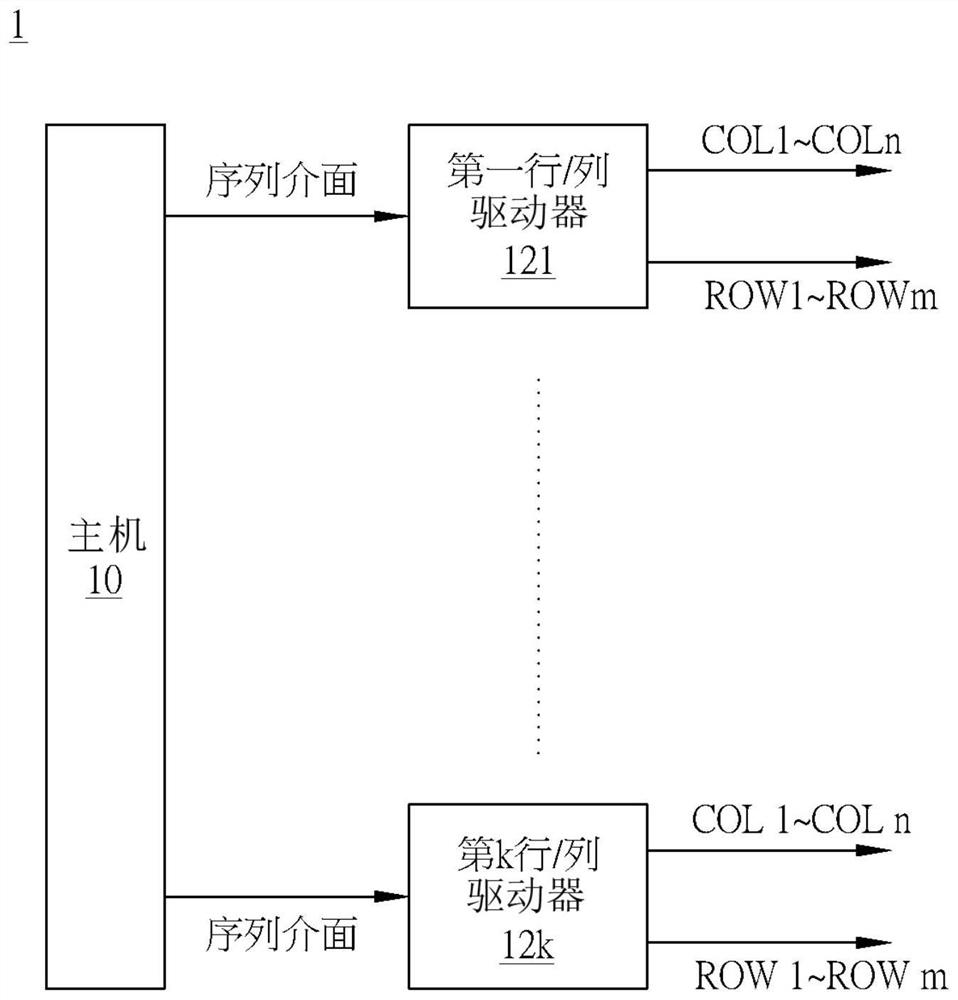

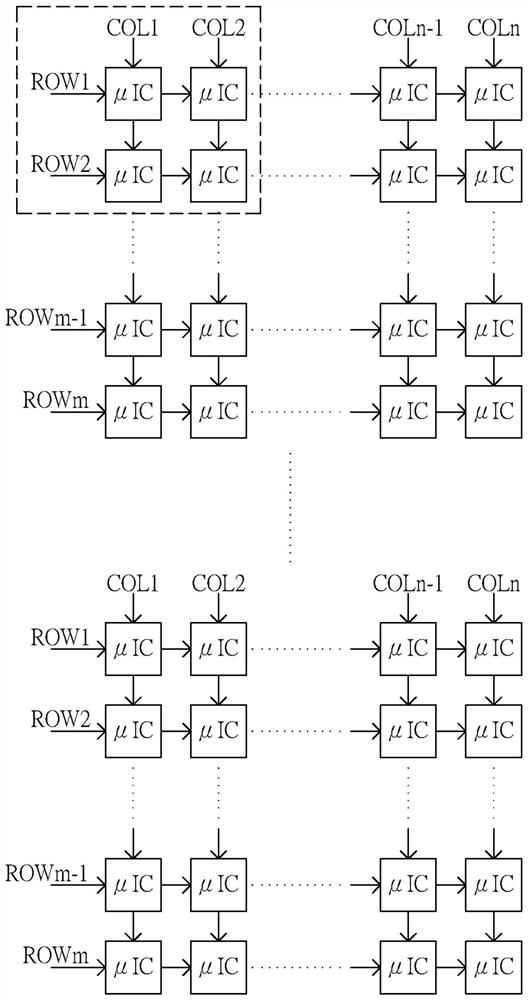

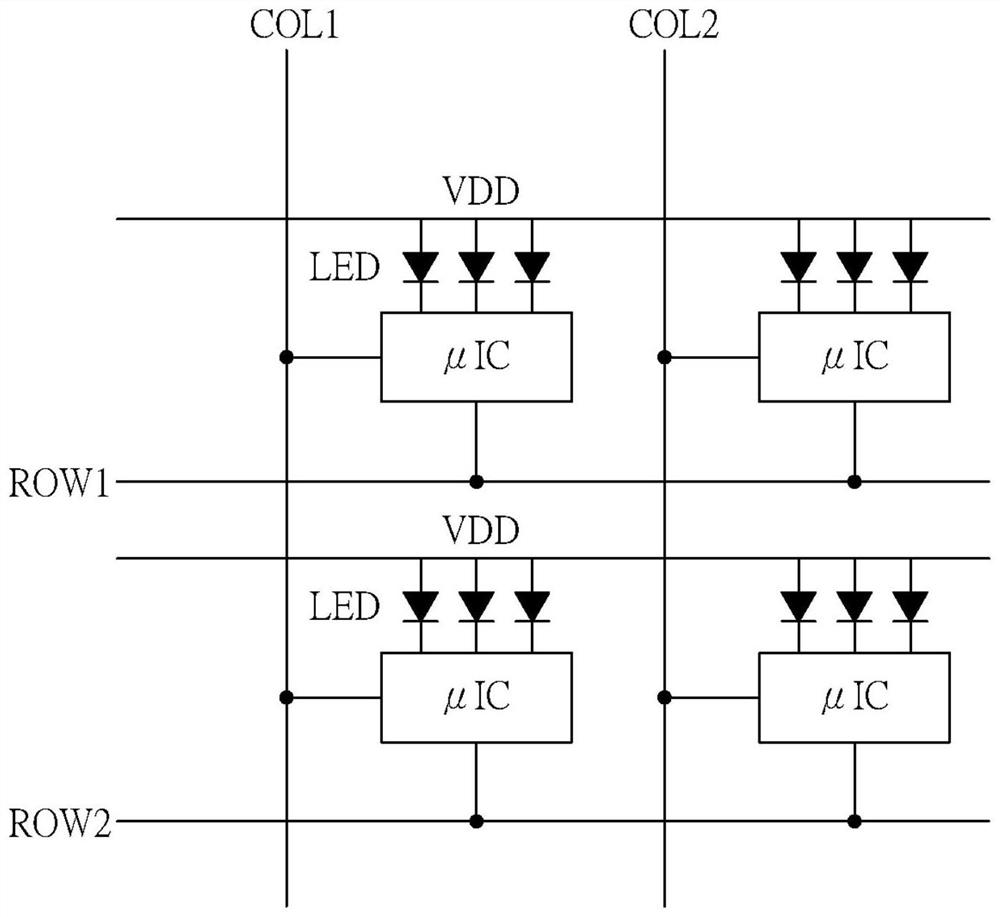

[0112] A specific embodiment according to the present invention is a micro-light-emitting diode (MICRO-LED) display system, such as an active matrix (Active Matrix) micro-light-emitting diode display system, which includes multiple row / column drivers and multiple micro-light-emitting diodes Integrated Circuit (μIC), but not limited thereto. As for its overall structure, please refer to Figure 1 and figure 2 , which will not be described further here.

[0113] Next, the micro LED integrated circuit (μIC) in several different embodiments proposed by the present invention will be described in detail respectively.

[0114] In the first embodiment, if Figure 5 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com