Method for determining finely-grinded mineral slag original content in hardened concrete

A technology for grinding slag and concrete, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as difficulty in detecting the content of ground ore powder, easy corrosion of steel bars, and easy engineering accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] China Resources Cement and Conch Cement are used respectively, the labels are both P·I42.5; the ground slag is produced by Shanxi Tongyang Building Materials Co., Ltd., the grade is S105, the above cement and ground slag are used as cementitious materials, and Beijing Fuwei Quartz sand (fineness modulus: 2.8) provided by Huiye Business Center was used as fine aggregate and mountain stone (calcium particle size 5-20 mm) was used as coarse aggregate to prepare concrete. dosage.

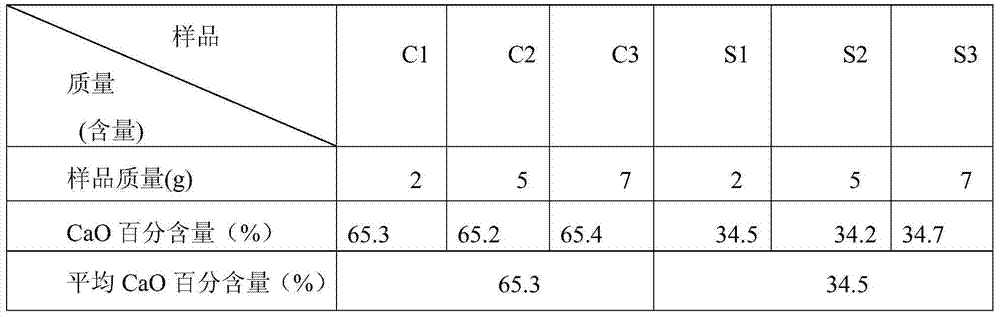

[0026] 1. Determination of CaO content in cement samples and ground slag samples

[0027] Different varieties of cement and ground slag were taken respectively, and the number of samples and the quality of each sample are shown in Table 1 and Table 2.

[0028] Table 1 Three samples of cement sample and three samples of ground slag and the quality of each sample

[0029]

[0030] C-China Resources cement sample, S-ground slag sample

[0031] Table 2 The cement sample and the ground slag sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com