Outer barrel template used for combined automated firework assembly production

A combination of fireworks and outer cylinder technology, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of low product added value, low labor efficiency, not to mention mechanization, etc., to eliminate dust occupational hazards, ensure safe production, The effect of working comfortably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

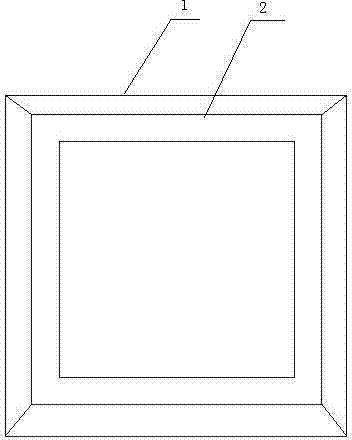

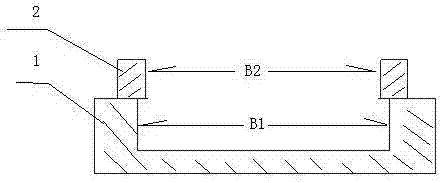

[0019] Such as Figure 1 to Figure 2 As shown, an outer tube template for automatic assembly production of combined fireworks is composed of an outer tube outer frame 1 and an outer tube inner frame 2 on which several outer tube bodies of the combined fireworks are installed. The outer tube outer frame 1 and the outer tube inner frame The frame 2 is a square frame or a rectangular frame, and the inner frame 2 of the outer cylinder is fixed on the end face of the outer frame 1 of the outer cylinder; or the inner frame 2 of the outer cylinder is embedded in the outer frame of the outer cylinder; the inner side length B1 of the outer frame of the outer cylinder is larger than the outer frame The inner side of the inner frame of the tube is B2.

[0020] The outer cylinder frame 1 has a square outer side length of 200 to 300 mm; the outer cylinder outer frame 1 has a square plate thickness of 25 to 35 mm; the outer cylinder inner frame 2 has a square outer side length of 180 to 280 mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com