A method for automatically dispensing process lubricating liquid in the rolling of sheet, strip and foil materials

A process lubrication and automatic liquid dosing technology, which is applied in the direction of manufacturing tools, metal processing equipment, workpiece surface treatment equipment, etc., can solve the problems of large changes in emulsion concentration, affecting production efficiency, and high labor intensity, so as to improve cold rolling production efficiency , Reduce the artificial labor intensity, the effect of small artificial labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

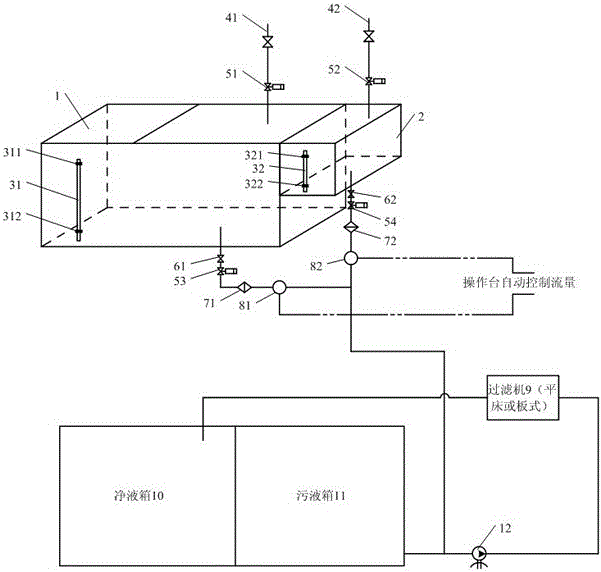

[0052] According to an embodiment of the present invention, an automatic liquid dispensing device for process lubricating liquid in the rolling of sheet, strip and foil is provided. Such as figure 1 As shown, this embodiment includes a mechanical part for dispensing the lubricating liquid of the corresponding process in the rolling of the plate and strip, and is used for real-time control of the liquid level and flow rate of the lubricating liquid of the corresponding process obtained by monitoring the mechanical part for the corresponding process. The control part of the liquid dispensing process of the lubricating liquid; the mechanical part is connected with the signal of the control part.

[0053] Wherein, the above-mentioned mechanical parts include a first liquid tank (such as the first liquid tank 1), a second liquid tank (such as the second liquid tank 2), a clean liquid tank (such as the clean liquid tank 10) and a dirty liquid tank (such as the dirty liquid tank 11)...

Embodiment 2

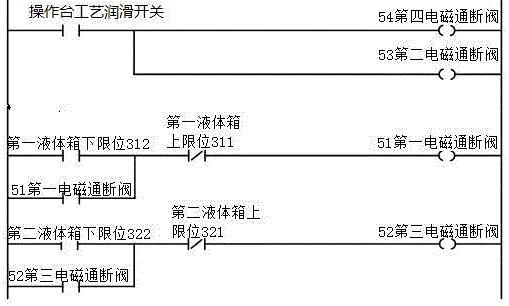

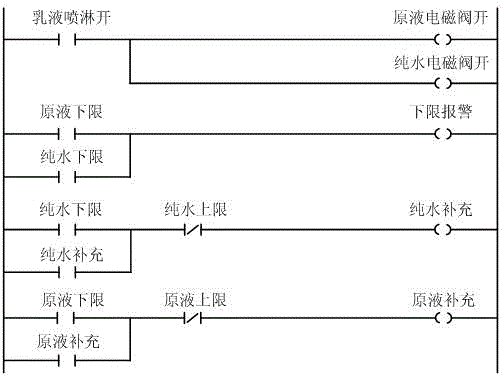

[0065] The difference from the above-mentioned embodiment is that, if figure 1 , figure 2 , Figure 2a and image 3 As shown, in this embodiment, the first liquid tank includes a water tank, the first liquid level gauge includes a water tank level gauge, and the first injection pipe includes a pure water pipe; the second liquid tank includes a crude oil tank, and the second liquid level gauge includes The crude oil level gauge, the second injection pipe includes a crude oil pipe; the filter includes a flat filter.

[0066] Specifically, in this embodiment, when the automatic liquid dispensing device for the process lubricating liquid in the strip and foil rolling is used in the hot rolling scheme, it consists of a mechanical part and a control part. For the mechanical part, see figure 1, consisting of a water tank and a crude oil tank, connecting 2 electromagnetic on-off valves, 2 ball valves, and 2 flowmeters through their respective pipelines; the control part can be fou...

Embodiment 3

[0072] The difference from the above-mentioned embodiment is that, if figure 1 , figure 2 , Figure 2b and Figure 4 As shown, in this embodiment, the first liquid tank includes an oil tank, the first liquid level gauge includes an oil level gauge, and the first injection pipe includes a filling pipe; the second liquid tank includes an additive tank, and the second liquid level gauge includes an additive The liquid level gauge, the second injection pipe includes an additive pipe; the filter includes a plate filter.

[0073] Specifically, in this embodiment, when the automatic liquid dispensing device for the process lubricating liquid in the strip and foil rolling is used in the cold rolling scheme, it consists of a mechanical part and a control part. The mechanical part can be found in figure 1 , consisting of an oil tank and an additive tank, connecting 2 electromagnetic on-off valves, 2 ball valves, and 2 flowmeters through their respective pipelines, the control part c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com