Pinion-and-rack rotating power generation car shock absorber

A technology of rack and pinion and shock absorber, applied in shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve problems such as low power generation efficiency and small linear displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

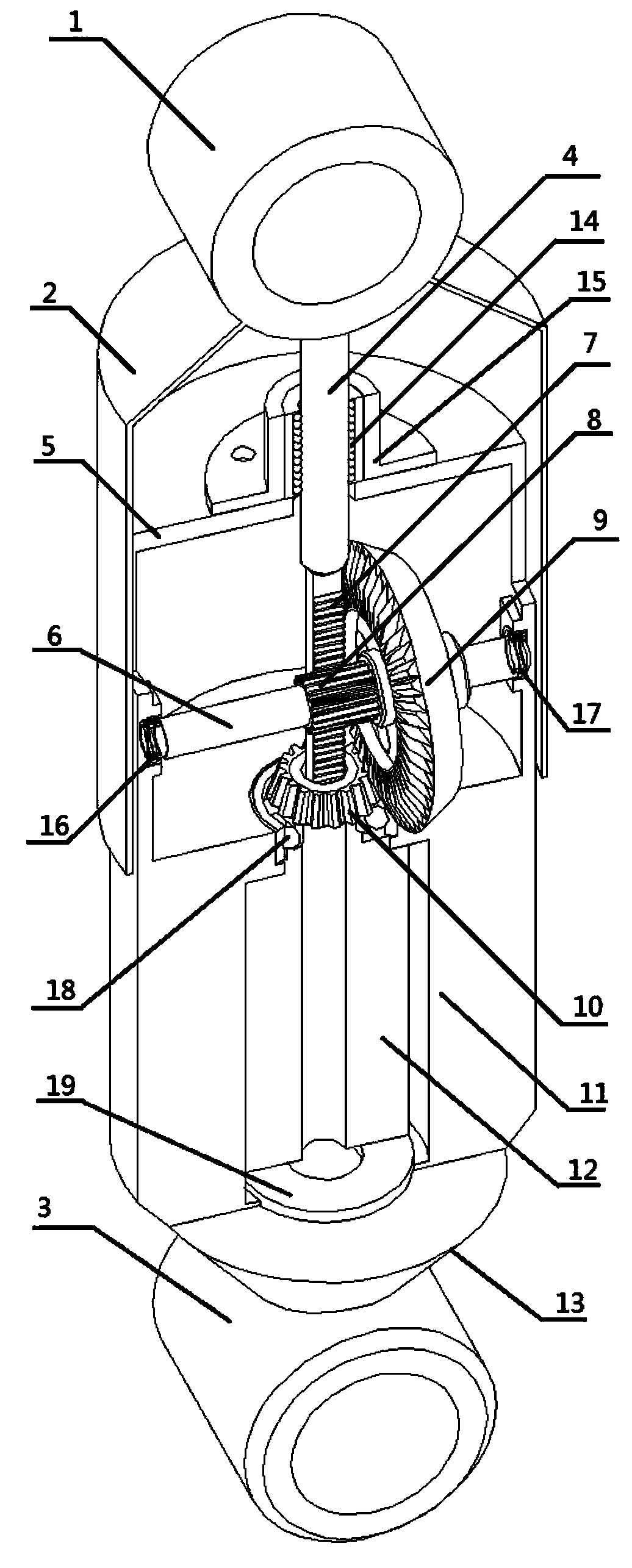

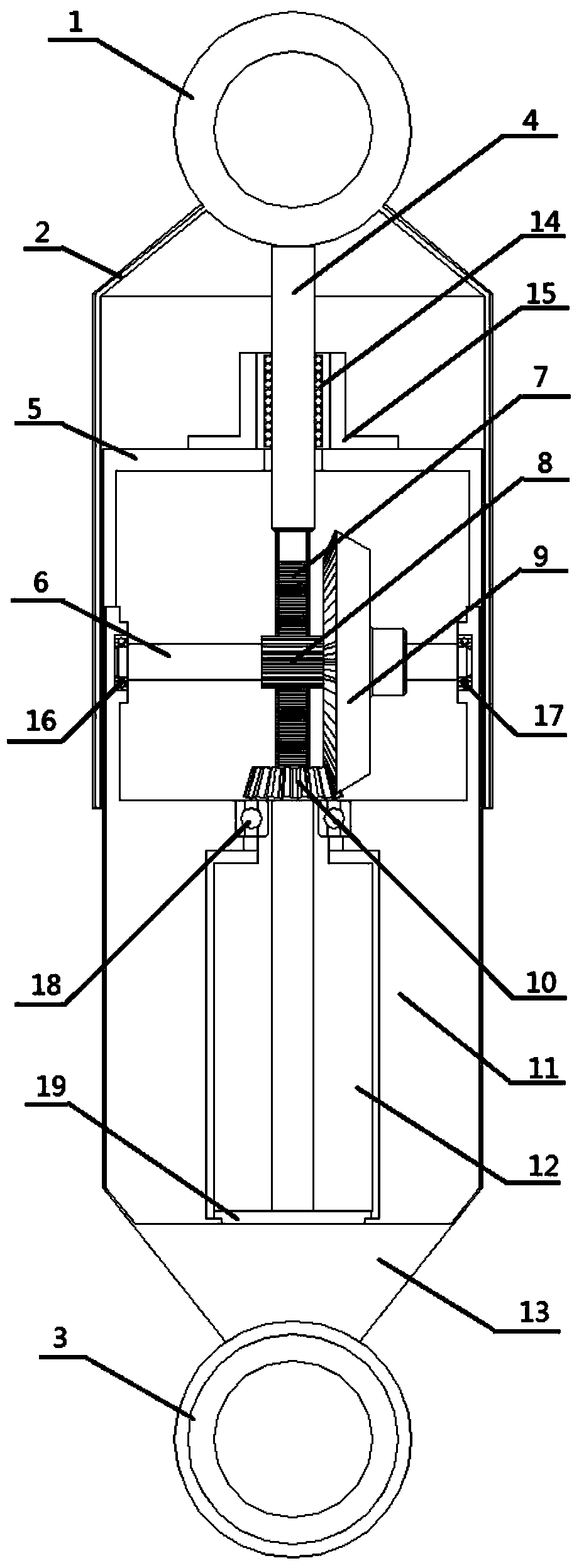

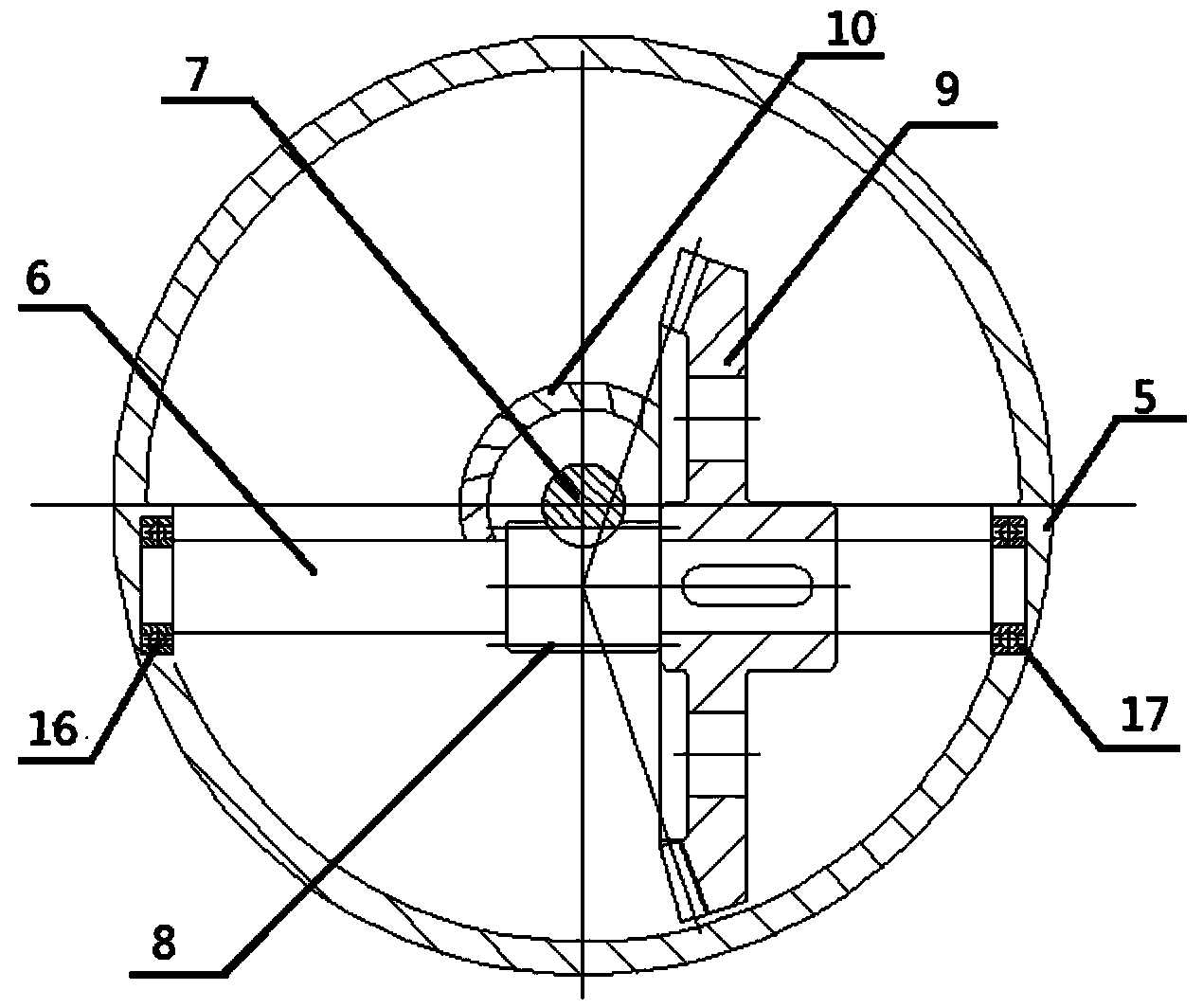

[0012] During operation, the upper suspension ring 1 is connected with the pin shaft of the automobile body, and the lower suspension ring 3 is connected with the pin shaft of the wheel shaft. During the driving process of the automobile, due to the impact, there is vibration, so that the housing 5 fixedly connected with the lower suspension ring 3 and the upper suspension ring 1 There is relative movement up and down in the fixedly connected rack 7 .

[0013] The up and down relative movement of the rack 7 relative to the housing 5 is converted into the rotational movement of the motor rotor 12 relative to the motor stator 11 through the gear 8, the shaft 6, the large hypoid gear 9 and the small hypoid gear 10, thereby generating electricity.

[0014] When the motor rotor 12 rotates relative to the motor stator 11, it will be affected by the magnetic resistance torque. This resistance plus the impact resistance generated by the gear meshing process makes the upper suspension r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com