Supporting method for primary support of underground excavated chamber

A technology of underground caverns and support methods, which is applied to underground caverns, pillars/brackets, earthwork drilling and mining, etc., and can solve problems such as numerous construction procedures and long construction periods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

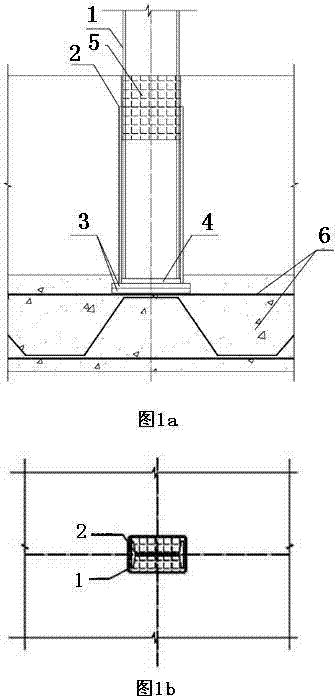

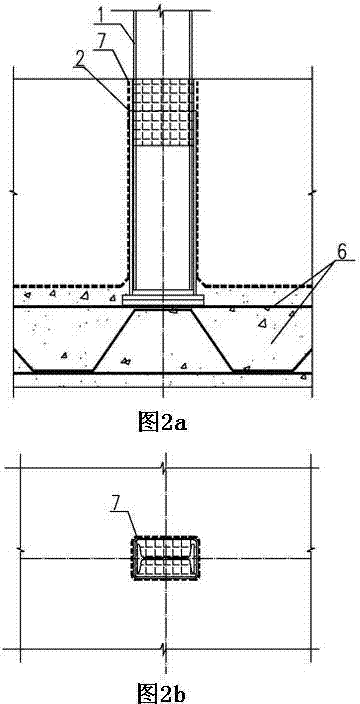

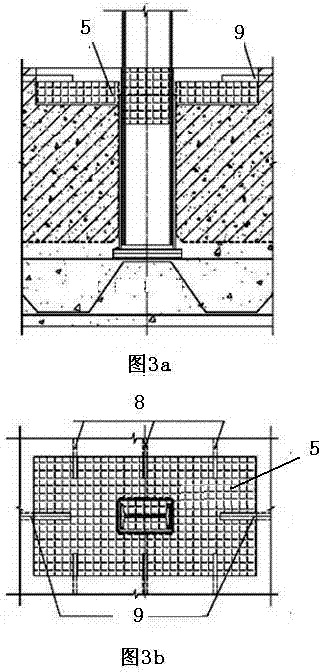

[0018] The present invention will be further described below in conjunction with accompanying drawing (taking a node at the bottom in the section of the underground cavern).

[0019] Description of components and material numbers in the attached drawings:

[0020] 1. For temporary steel support, I-beam can be used;

[0021] 2. Rectangular steel pipe;

[0022] 3. Steel backing plate;

[0023] 4. Temporary support steel end plate;

[0024] 5. Light and cheap materials, plastic foam products can be used;

[0025] 6. Initial support steel frame (grid arch frame) for initial support lining;

[0026] 7. Waterproof layer;

[0027] 8. Longitudinal distribution reinforcement in the secondary lining;

[0028] 9. The main reinforcement in the secondary lining;

[0029] 10. Secondary lining concrete;

[0030] 11. The waterproof layer covered by rectangular steel pipes poured with concrete;

[0031] 12. Reinforcement welded with secondary lining main reinforcement and distributed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com