A polysilicon ingot furnace argon diversion system and diversion method

A polycrystalline silicon ingot furnace and argon technology, which is applied in the field of argon diversion system, can solve the problems of not effectively improving the argon flow, unable to effectively reduce the oxygen and carbon content, and difficult to control the argon transportation, so as to achieve convenient control. , The effect of reducing vapor pressure and reducing impurity concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

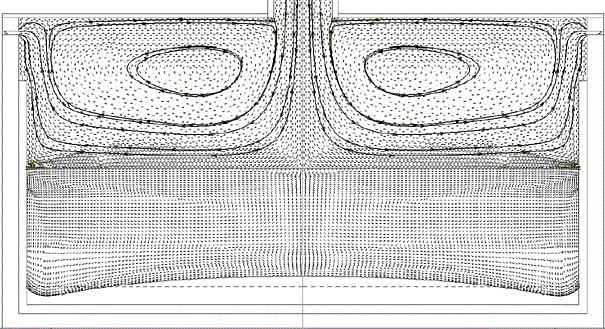

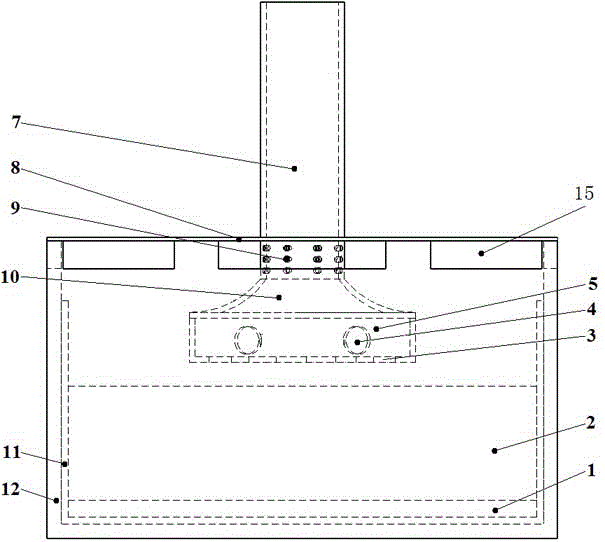

[0039] Such as image 3 — Figure 9As shown, the center hole 13 of the cover plate is opened in the center of the cover plate 8, and several rectangular cover plate air outlets 14 are arranged symmetrically along the cover plate central hole 13 on the cover plate 8. The argon inlet straight pipe 7 passes through the central hole 13 of the cover plate, the outlet end of the argon inlet straight pipe 7 is coaxially connected with the trumpet-shaped inlet pipe 10, and the outlet end of the trumpet-shaped inlet pipe 10 is coaxial with the spray inlet pipe 5 connected, the spray inlet pipe 5 is a pipe with a bottom, the bottom of the spray inlet pipe 5 is symmetrically distributed with a number of circular bottom air holes 3 along the central axis of the argon inlet straight pipe, and the spray inlet pipe The side wall of 5 is also symmetrically opened with a number of circular side wall air holes 4 along the central axis of the argon gas inlet straight pipe. Argon gas inlet stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com