Flexible polyvinyl chloride cable material and preparation method thereof

A technology of polyvinyl chloride cable and soft polyvinyl chloride, applied in plastic/resin/wax insulators, organic insulators, etc., to reduce material costs, improve product market competitiveness, and improve flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A preparation method of soft polyvinyl chloride cable material, comprising the following steps:

[0022] (1) Weigh the raw materials according to the above formula, add polyvinyl chloride resin and nano-calcium carbonate to the high-mixer and stir at a speed of 700-800 r / min for 5-10 minutes, then add antioxidant to the above-mentioned mixture Bisphenol A, lubricant, composite heat stabilizer, pigment, vinyl chloride-butyl acrylate resin, stir for 1-2min, and finally add dioctyl phthalate and dioctyl sebacate, at 700-800 r / Mix evenly at a speed of min.

[0023] (2) Send the mixture obtained in step (1) into a single-screw cable extruder with a diameter of 70mm and a length-to-diameter ratio of 25:1 to extrude and pelletize. The temperature is controlled at 100-170°C and the line speed is 10m / min to produce finished products. The internal temperature of the single-screw cable extruder is set as follows: first stage temperature: 100-110°C, second stage temperature: 14...

Embodiment

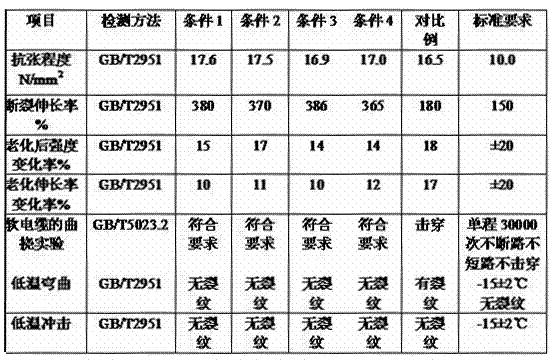

[0025] Plasticizer, also known as plasticizer, is a polymer material additive widely used in industry. Adding this substance in plastic processing can enhance its flexibility. Therefore, this example examines the influence of the amount of different plasticizers and co-plasticizers on the performance of the cable, and its raw material formula is shown in Table 1 below:

[0026] Raw materials (kg) Condition 1 Condition 2 Condition 3 Condition 4 comparative example PVC resin 100 100 100 100 100 Dioctyl phthalate 16 16 16 18 32 Dioctyl sebacate 16 16 8 12 - Vinyl chloride-butyl acrylate resin 16 16 24 20 - Petroleum ester (T-50) 6.8 - 6.8 - 11.2 Chlorinated paraffin - 6.8 - 6.8 11.2 Nano calcium carbonate 15 15 20 20 15 antioxidant 1.2 1.2 1.2 1.2 1.2 lubricant 1.6 1.6 1.8 1.8 1.6 pigment 0.8 0.8 1.0 1.0 0.8 Composite heat stabilizer 6.8 6.8 6.8 6.8 6.8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com