Recovering system and method of C2 in refinery dry gas by compound adsorption method

A technology of refinery dry gas and absorption method, which is applied in absorption purification/separation, ethylene production, organic chemistry, etc. It can solve the problems of adverse effects of the device, low purity of recovered ethylene, limited scope of application, etc., and achieves ease of operating conditions, Reasonable effect of process cooling consumption level and quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Below in conjunction with embodiment, further illustrate the present invention, but the present invention is not limited to following embodiment.

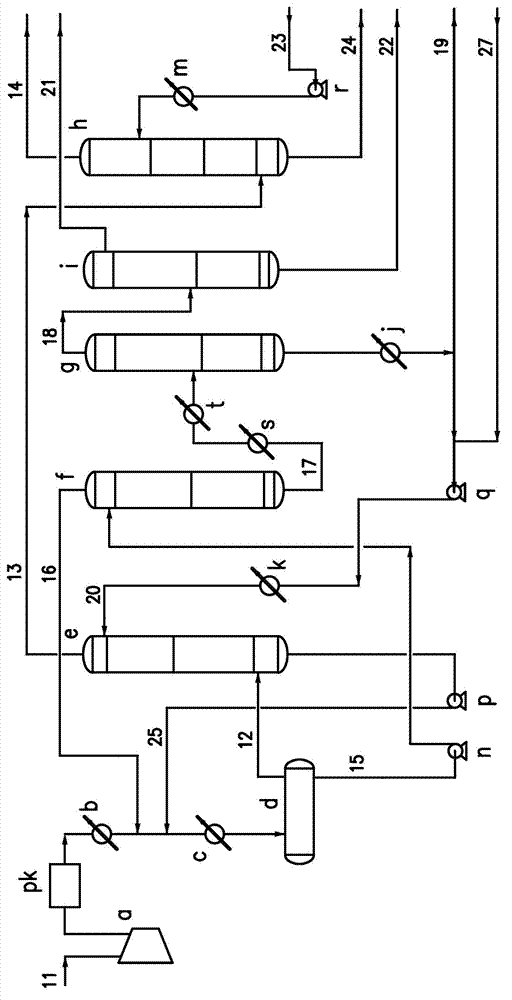

[0056] figure 1 It shows a system flow chart of recovering carbon dioxide in refinery dry gas by a combined absorption method of the present invention. The system includes compressor a, pretreatment unit pk, refinery dry gas cooling unit, absorption unit and rectification unit, and the combined absorption unit includes gas-liquid separation tank d, carbon dioxide absorption tower e and methane desorption tower f , the rectification unit includes a decarburization tower g and an ethylene rectification tower i.

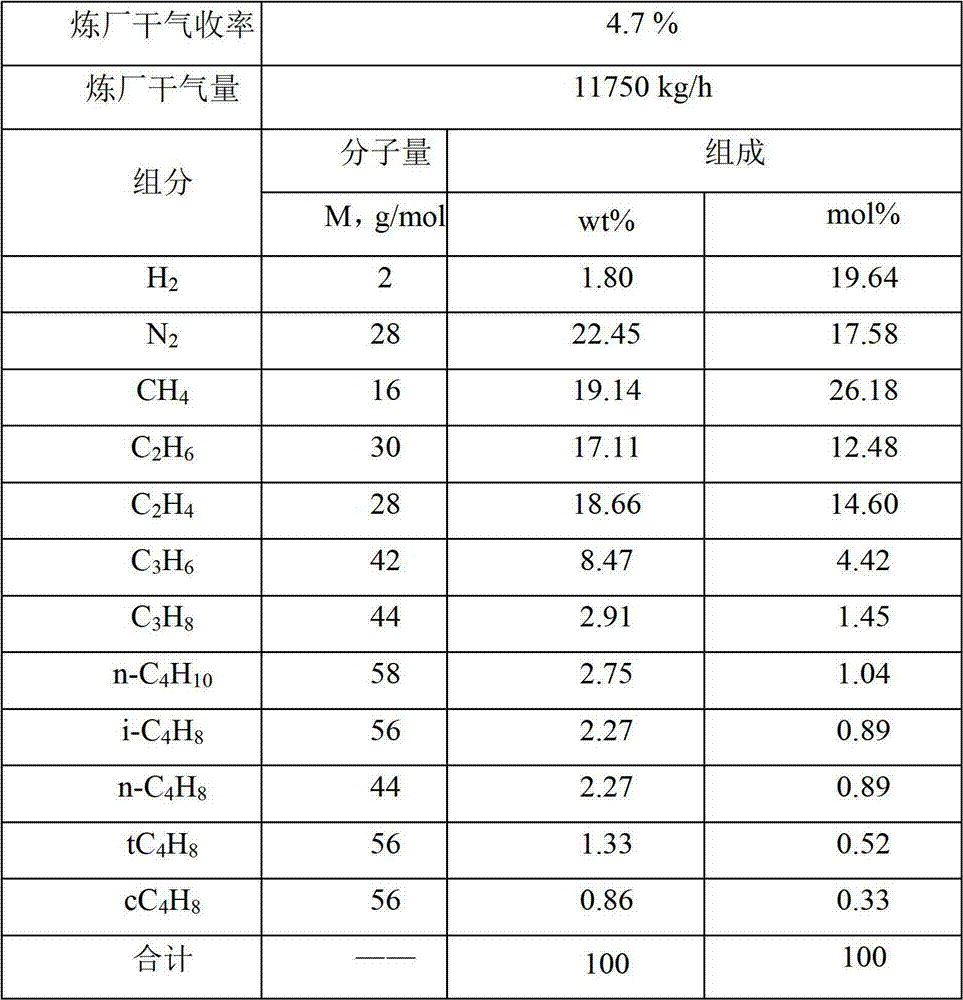

[0057] The dry gas composition of the refinery is shown in Table 1. The refinery dry gas feed pipeline is sequentially connected to the compressor a, the pretreatment unit pk, and the refinery dry gas cooling unit, and then connected to the material inlet of the gas-liquid separation tank d.

[0058] The upper part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com