Oilfield fracturing wastewater treatment equipment

A technology for waste liquid treatment and oil field fracturing, applied in water/sewage treatment, flotation water/sewage treatment, oxidized water/sewage treatment, etc. To achieve the effect of convenient use, wide application range, and saving construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

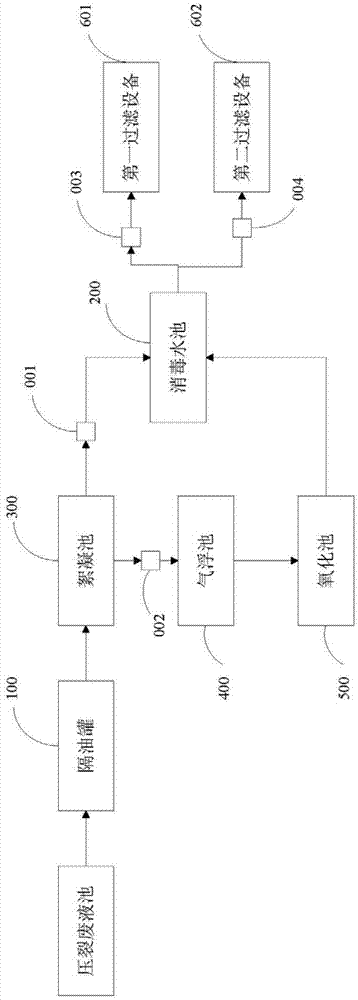

Image

Examples

Embodiment 1

[0040] The destination of the oilfield fracturing waste fluid in this embodiment is to be collected into the gathering and transportation system or reinjected into the formation. In the collection and transportation system, the fracturing waste fluid is generally collected and processed through a certain process, and then mixed with the oil production sewage according to a certain proportion for reprocessing, and the treated water quality is uniformly collected and transported to the oil gathering station for treatment by the oil and gas gathering and transportation pipeline; The fracturing waste fluid collected into the gathering and transportation system is mainly for the removal of sensory substances. The main indicators include suspended solids (SS), chroma, turbidity, etc. At the same time, a low dissolved oxygen concentration in the effluent should be ensured. The re-injection of fracturing waste fluid into the formation is a treatment method adopted by some oil and gas f...

Embodiment 2

[0048] Discharging fracturing waste liquid directly after treatment is the mainstream method at present, but the treatment requirements are high, and the treated water must meet the national comprehensive sewage discharge standard (GB8978-1996). Mainly to remove COD, petroleum, SS, etc.

[0049] When the oil field fracturing waste liquid is discharged directly after treatment, the flocculation tank 300 is an electrocoagulation tank; the first control valve 001 is closed, the second control valve 002 is opened, and the third control valve 003 is closed , the fourth control valve 004 is opened. Alternatively, two movable partitions divide the comprehensive reaction tank into a flocculation tank, an air flotation tank and an oxidation tank, and the flocculation tank, the air flotation tank and the oxidation tank are respectively treated differently.

[0050] When oil field fracturing waste fluid is discharged directly after treatment, it must meet the discharge standard, so its ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com