Method and special-purpose device for producing chlorine dioxide disinfectant having concentration of 4%

A chlorine dioxide and production method technology, applied in the direction of chlorine oxide, disinfectant, botany equipment and methods, etc., to achieve the effect of increasing investment, improving safety, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

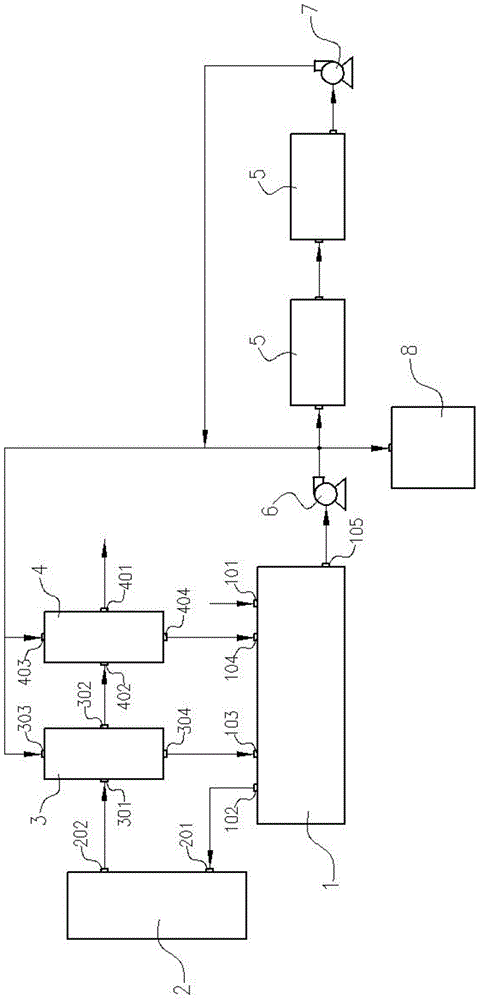

[0029] Such as figure 1 As shown, the special equipment for producing 4% chlorine dioxide disinfectant of the present invention includes: absorption tank 1, including absorption liquid inlet 103,104, air inlet 101, hot gas outlet 102 and mixed absorption liquid outlet 105, the absorption The liquid inlets 103 and 104 are respectively connected with the absorption tower 3 and the washing tower 4; the reaction kettle 2 includes a hot gas inlet 201 and a reaction gas outlet 202, and the hot gas inlet 201 is connected with the hot gas outlet 102 of the absorption tank 1, and the reaction Still 2, described absorption tower 3 and described washing tower 4 are communicated in sequence through chlorine dioxide gas guide pipe, and described washing tower 4 also comprises the air outlet 401 that is communicated with atmosphere;

[0030] Absorption pump 6, the inlet end of which is connected to the mixed absorption liquid outlet 105 of the absorption tank 1, the pipeline connected to th...

Embodiment 2

[0032] Such as figure 1 Shown, the special equipment of producing 4% chlorine dioxide disinfectant of the present invention comprises:

[0033] The absorption tank 1 is provided with an absorption liquid inlet, an air inlet 101 and a hot gas outlet 102 at the upper part, and a mixed absorption liquid outlet 105 is provided at the lower part of the absorption tank 1, and the air inlet 101 and the hot gas outlet 102 are respectively arranged at the The two sides of the absorption liquid inlet, the absorption liquid inlet includes a first absorption liquid inlet 103 and a second absorption liquid inlet 104;

[0034] Reactor 2, which includes a hot gas inlet 201 and a first reaction gas outlet 202, and the hot gas inlet 201 communicates with the hot gas outlet 102 of the absorption tank 1;

[0035]Absorption tower 3, which comprises a first reaction gas inlet 301, a second reaction gas outlet 302, a third absorption liquid inlet 303 and a first absorption liquid outlet 304, the f...

Embodiment 3

[0040] A method of producing 4% chlorine dioxide disinfectant, comprising the steps:

[0041] The chlorine dioxide gas produced in the reaction kettle 2 and the hot gas produced by the absorption tank 1 and passed into the reaction kettle 2 are continuously and sequentially transported to the absorption tower 3 and the washing tower 4 through the air duct, and the washed Discharge after gas inspection is qualified; All contain absorption liquid in described absorption tower 3, washing tower 4 and absorption tank 1, described absorption liquid in described absorption tower 3 and described washing tower 4 enters after absorbing chlorine dioxide gas After the absorption tank 1 is mixed with the absorption liquid therein, a part is directly passed into the absorption tower 3 and the washing tower 4 to circulate and absorb chlorine dioxide gas, and the other part passes through the cooler 5 on-line to exchange heat and cool down to make cooling absorption control the temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com